A wire laser cladding device

A laser cladding and wire technology, applied in metal material coating process, coating and other directions, can solve the problems of low cladding efficiency, many defects, hinder the development of wire laser cladding technology, etc., and achieve the effect of flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

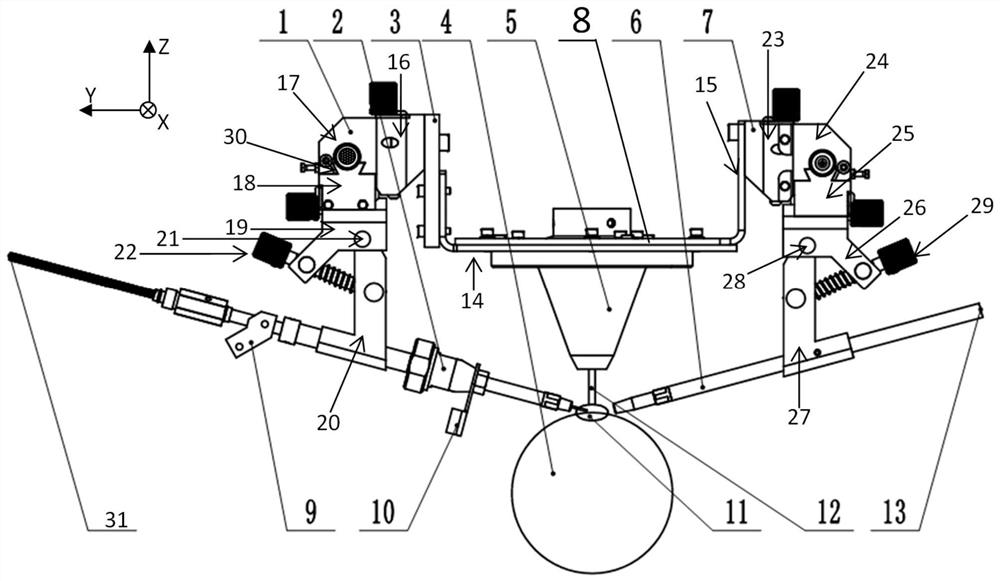

[0038] In this embodiment, the laser cladding device for workpieces according to the present invention is used for laser cladding processing of workpieces. Specifically, hot wire laser cladding is performed on a cylindrical workpiece. First, the workpiece 4 is clamped to a workbench with a rotating function. Above, the laser head 5 is mounted on a worktable that moves along the axis of the workpiece 4 .

[0039] In this example, the heating wire can be used in advance, that is, the first electrode interface 9 and the second electrode interface 10 are respectively connected to the two poles of the heating wire machine, and there is an insulating terminal and an insulating tube between the first electrode interface 9 and the second electrode interface 10. After passing through, it can only conduct electricity through the welding wire, so as to realize heating; or the workpiece 4 conductive heating wire can be used, that is, the first electrode interface 9 is connected with one el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com