Preparation method of high-purity metal hafnium

A high-purity, metal technology, applied in the field of rare metals, can solve the problems of uneven particle size, low purity of metal hafnium, complex process, etc., and achieve the effect of uniform size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing high-purity metal hafnium, including:

[0024] S1. Dissolve the hafnium tetrachloride solid in deionized water to obtain a hafnium oxychloride solution with a concentration of 0.01g / mL. At room temperature, slowly add the sodium hydroxide solution with a concentration of 0.01g / mL to the oxygen chloride In the hafnium solution, a mixed solution is obtained;

[0025] S2. Pour the mixed solution into a high-pressure hydrothermal reaction kettle, put the reaction kettle in an oven, the temperature of the oven is 120°C, and place it in the oven for 12 hours;

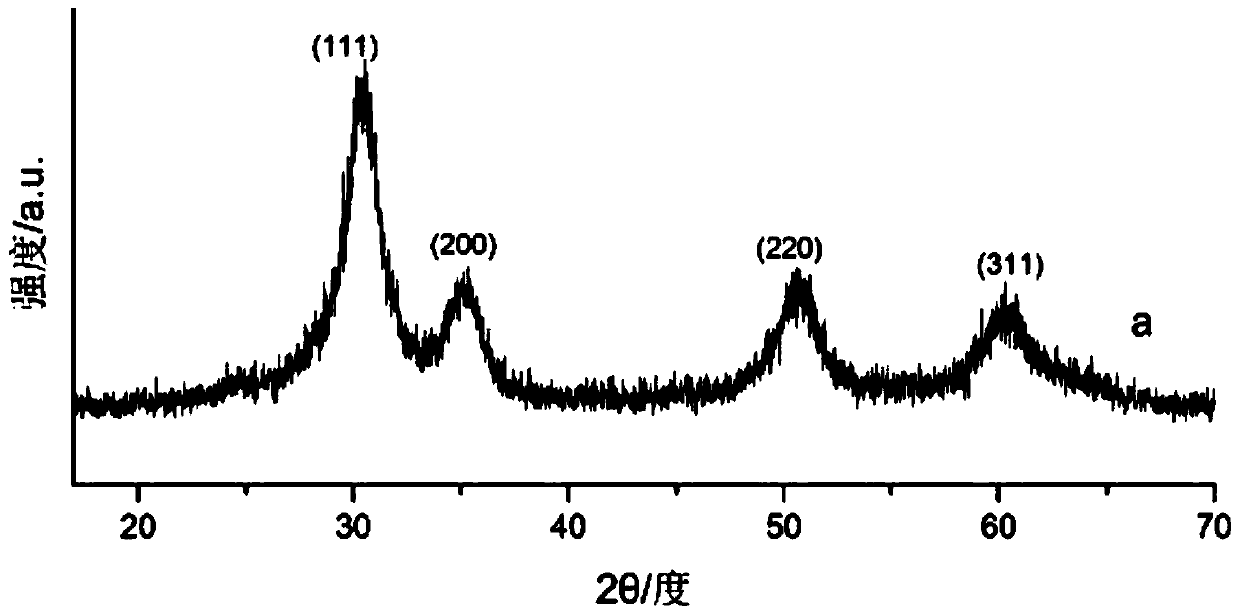

[0026] S3. Pour the suspension of the reaction kettle into the flask, wash the solid obtained by centrifugation with ethanol and deionized water alternately, centrifuge, and repeat three times. The final product is dried at 60℃ for 12h to obtain hafnium oxide, such as figure 1 As shown, the positions of the diffraction peaks of hafnium oxide are 24.64°, 28.30°, 31.76° and 50.46°, and the corresponding c...

Embodiment 2

[0029] A method for preparing high-purity metal hafnium, including:

[0030] S1. Dissolve the solid hafnium tetrachloride in deionized water to obtain a hafnium oxychloride solution with a concentration of 0.05g / mL. At room temperature, slowly add a sodium hydroxide solution with a concentration of 0.05g / mL to the oxygen chloride. In the hafnium solution, a mixed solution is obtained;

[0031] S2. Pour the mixed solution into a high-pressure hydrothermal reaction kettle, put the reaction kettle in an oven, the temperature of the oven is 100°C, and place it in the oven for 24 hours;

[0032] S3. Pour the suspension in the reaction kettle into the flask, wash the solid obtained by centrifugation alternately with ethanol and deionized water, centrifuge, and repeat three times. The final product obtained is dried at 60°C for 24 hours to obtain hafnium oxide, monoclinic crystal form, Hafnium oxide with a particle size of 120nm;

[0033] S4. Mixing excess Ca powder with a particle size of ...

Embodiment 3

[0035] A method for preparing high-purity metal hafnium, including:

[0036] S1. Dissolve the hafnium tetrachloride solid in deionized water to obtain a hafnium oxychloride solution with a concentration of 0.02g / mL. At room temperature, slowly add a sodium hydroxide solution with a concentration of 0.02g / mL to the oxygen chloride In the hafnium solution, a mixed solution is obtained;

[0037] S2. Pour the mixed solution into a high-pressure hydrothermal reaction kettle, and place the reaction kettle in an oven with a temperature of 110°C and place it in the oven for 16 hours;

[0038] S3. Pour the suspension of the reaction kettle into the flask, wash the solid obtained by centrifugation alternately with ethanol and deionized water, centrifuge, and repeat three times. The final product obtained is dried at 50°C for 16 hours to obtain hafnium oxide, monoclinic crystal, Hafnium oxide with a particle size of 80nm;

[0039] S4. Mixing excess Ca powder with a particle size of 1 μm and haf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com