Blast furnace blown pulverized coal and air heating furnace air/coal gas series connection preheating process and system

A technology of gas preheater and air preheater, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as waste of heat, high preheating temperature, and high outlet temperature, and achieve improved combustion rate and coal injection The effect of increasing the air temperature level and high preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

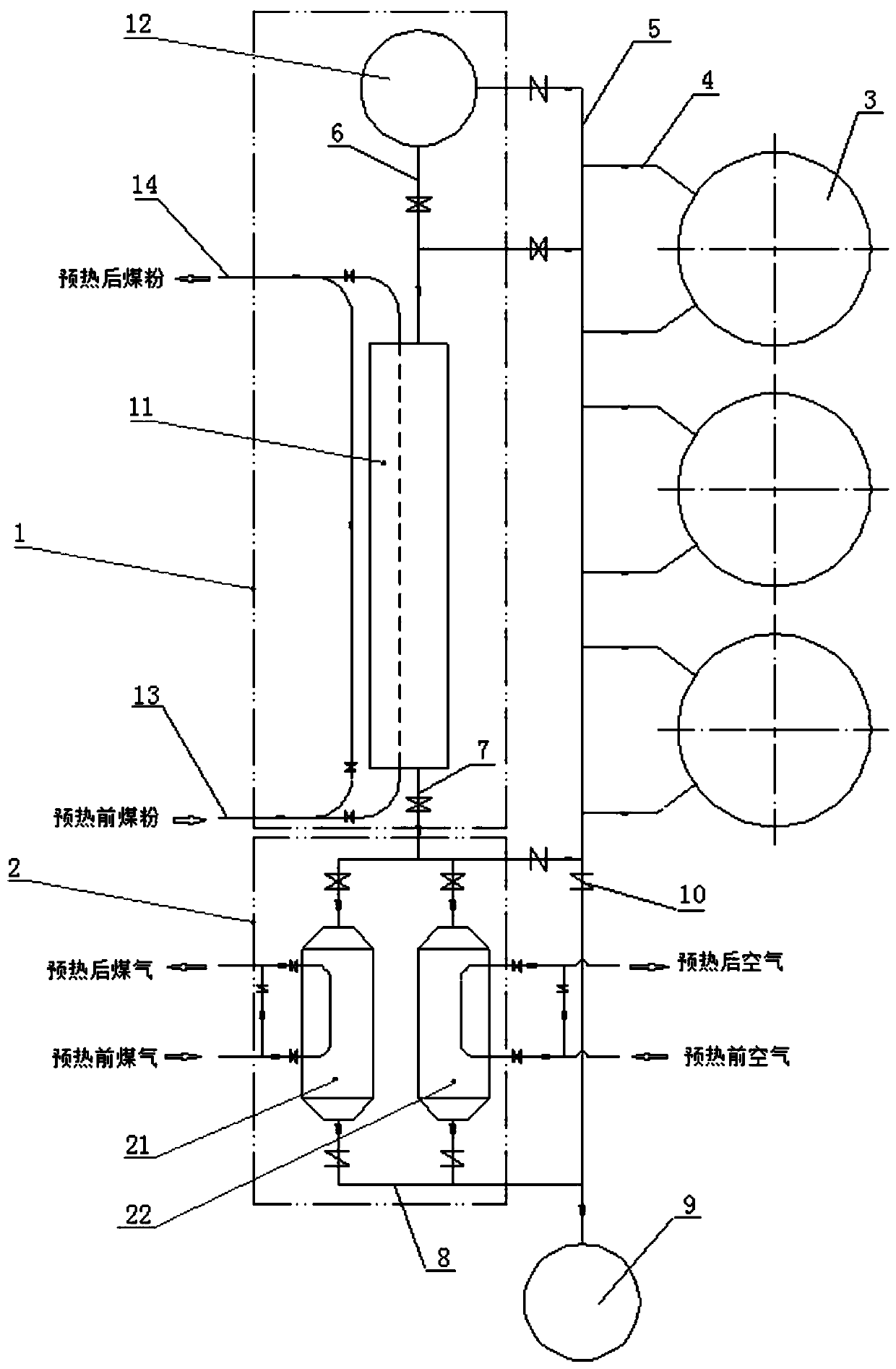

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] Blast furnace pulverized coal injection and hot blast stove air / gas preheating process in series, the high temperature flue gas from hot blast stove 3 first enters pulverized coal preheating system 1 for coal preheating, and the flue gas after heat exchange enters air / gas preheating Thermal system 2 is used for air and / or gas preheating to realize graded utilization of high-temperature flue gas waste heat.

[0026] Blast furnace pulverized coal injection and hot blast stove air / coal gas series preheating process, specifically including: the high temperature flue gas at 250-350°C drawn from the hot blast stove 3 is directly sent to the pulverized coal preheater 11, or the high temperature flue gas passes through the combustion furnace first 12 heats up to 300°C-600°C and then sends it to the pulverized coal preheater 11, and preheats the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com