Compound enzyme, highly-fragrant rapeseed oil processing method, highly-fragrant rapeseed oil and edible oil

A processing method, Luzhou-flavored technology, applied in the field of edible oil, can solve the problems of long processing time, high cost, single enzyme, etc., and achieve the effect of good effect, low cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

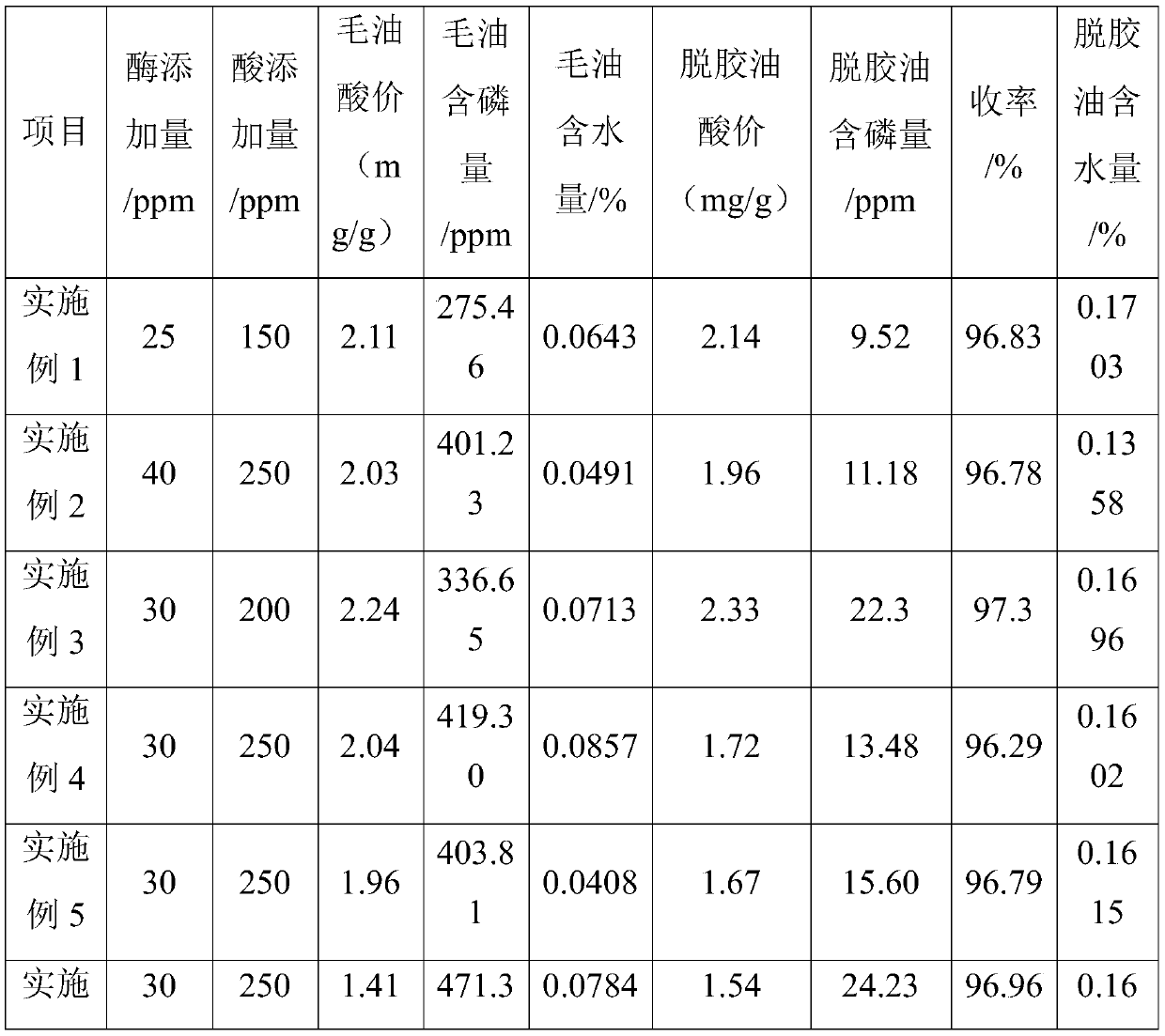

Embodiment 1

[0064] After being transported by a metering oil pump, the crude oil enters the pipeline through a leaf filter, and the oil temperature is controlled at about 53°C through a heat exchanger to obtain crude rapeseed oil; the amount of citric acid is controlled to 150ppm, and the crude rapeseed oil is mixed with citric acid Enter the acid reaction tank after being mixed by a mixer, and stir for 20 minutes at a stirring speed of 100 rpm / min to obtain an acid reaction liquid;

[0065] According to the consumption of compound enzyme is 25ppm, the consumption of water is 1.5wt% of rapeseed crude oil, the acid reaction solution is mixed through the steam explosion system together with water and compound enzyme through the oil pump, enters the enzyme reaction tank to react, and the reaction time is 100 Minutes to obtain the enzyme reaction solution; wherein, the complex enzyme, in terms of enzyme activity, includes phospholipase A 8684U / g, phospholipase C 7642U / g, protease 4414U / g and c...

Embodiment 2

[0068] After being transported by a metering oil pump, the crude oil enters the pipeline through a leaf filter, and the oil temperature is controlled at about 50°C through a heat exchanger to obtain rapeseed crude oil; the amount of citric acid is controlled to 250ppm, and the rapeseed crude oil is mixed with citric acid Enter the acid reaction tank after being mixed by a mixer, and stir for 40 minutes at a stirring speed of 80rpm / min to obtain an acid reaction liquid;

[0069] According to the consumption of compound enzyme is 40ppm, the consumption of water is 2.5wt% of rapeseed crude oil, the acid reaction solution is mixed through steam explosion system together with water and compound enzyme through oil pump, enters enzyme reaction tank reaction, and reaction time is 150 Minutes to obtain the enzyme reaction solution; wherein, the complex enzyme, in terms of enzyme activity, includes phospholipase A 8092U / g, phospholipase C 7915U / g, protease 4154U / g and cellulase 4618U / g; ...

Embodiment 3

[0072] After being transported by a metering oil pump, the crude oil enters the pipeline through a leaf filter, and the oil temperature is controlled at about 55°C through a heat exchanger to obtain crude rapeseed oil; the amount of citric acid is controlled to 200ppm, and the crude rapeseed oil is mixed with citric acid Enter the acid reaction tank after being mixed by a mixer, and stir for 30 minutes at a stirring speed of 90 rpm / min to obtain an acid reaction liquid;

[0073] According to the consumption of compound enzyme is 30ppm, the consumption of water is 2.0wt% of rapeseed crude oil, the acid reaction solution is mixed through the steam explosion system together with water and compound enzyme through the oil pump, enters the enzyme reaction tank to react, and the reaction time is 120 Minutes to obtain the enzyme reaction solution; wherein, the complex enzyme, in terms of enzyme activity, includes phospholipase A 8751U / g, phospholipase C 7317U / g, protease 4767U / g and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com