Nano-micron pressure-bearing plugging agent for drilling fluid, and evaluation method thereof

A technology of pressure-bearing plugging agent and evaluation method, applied in chemical instruments and methods, drilling composition, construction, etc., can solve the problems of material waste cost, failure to pass, lack of experimental results, etc., and achieve good plugging effect , Good blocking effect, and the effect of reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a pressure-bearing plugging agent for nano-micron drilling fluid, which is composed of the following raw materials in parts by weight: 91 parts of calcium carbonate micro particles, 3 parts of silica nanoparticles, 28 parts of fine fibers and 2 parts of nano Titanium dioxide surface treatment agent;

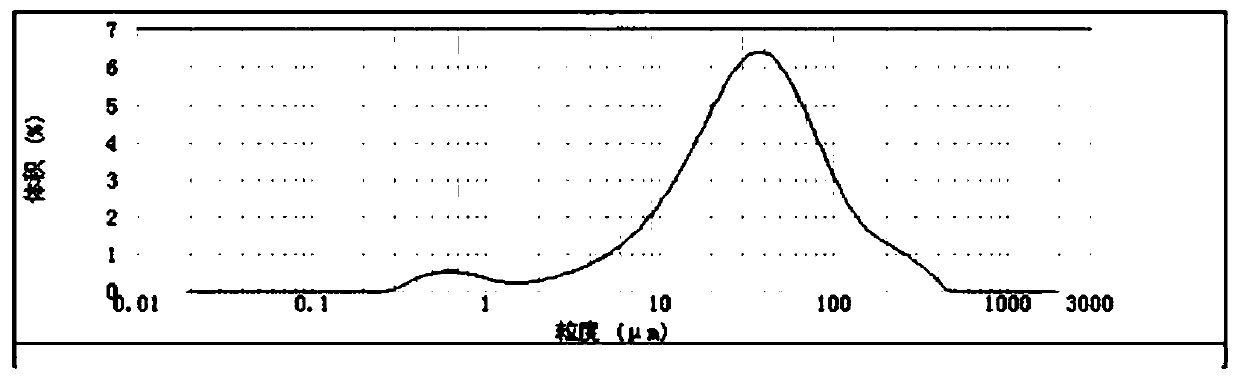

[0033] Specifically, the particle size of calcium carbonate micron particles is normally distributed in the interval of 1-450 microns, such as figure 1 As shown, the micron-sized particles with a particle size of 1-10 μm account for 14% of the total volume of the micron-sized particles, the micron-sized particles with a particle size of 10-50 μm account for 55% of the total volume of the micron-sized particles, and the micron-sized particles with a particle size of 50-100 μm The particles accounted for 17% of the total volume of the micron-sized particles, and the micron-sized particles with a particle diameter of 100-450 μm accounted for 14% of th...

Embodiment 2

[0041] This embodiment provides a pressure-bearing plugging agent for nano-micron drilling fluid, which is composed of the following raw materials in parts by weight: 95 parts of calcium carbonate micro-particles and aluminum oxide micro-particles mixed in any proportion, 3 parts in any proportion Mixed silica nanoparticles, iron ferric oxide nanoparticles and calcium carbonate nanoparticles, 20 parts of fine fibers and 2 parts of nano-titanium dioxide surface treatment agent;

[0042] Specifically, the particle diameters of calcium carbonate micro-particles and aluminum oxide micro-particles mixed in any proportion are normally distributed within the interval of 1-450 microns, specifically as figure 1 As shown, the micron-sized particles with a particle size of 1-10 μm account for 14% of the total volume of the micron-sized particles, the micron-sized particles with a particle size of 10-50 μm account for 55% of the total volume of the micron-sized particles, and the micron-si...

Embodiment 3

[0050] This embodiment provides a pressure-bearing plugging agent for nano-micro drilling fluid, which is composed of the following raw materials in parts by weight: 97 parts of calcium carbonate micro-particles, aluminum oxide micro-particles and titanium dioxide micro-particles mixed in any proportion, 3 Parts of silicon dioxide nanoparticles, iron ferric oxide nanoparticles, calcium carbonate nanoparticles and zinc oxide nanoparticles mixed in any proportion, 20 parts of fine fibers and 2 parts of nano-titanium dioxide surface treatment agent;

[0051] Specifically, the particle diameters of calcium carbonate micro-particles, aluminum oxide micro-particles and titanium dioxide micro-particles mixed in any proportion are normally distributed within the range of 1-450 microns, specifically as figure 1 , wherein micron-sized particles with a particle size of 1-10 μm account for 14% of the total volume of micron-sized particles, micron-sized particles with a particle size of 10-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com