Surface-chemically-modified mica iron oxide powder and preparation method thereof

A technology of mica iron oxide and surface chemistry, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, coatings, etc., can solve the problems affecting the quality and storage stability of coatings, agglomeration of mica iron oxide powder, and damage to lamellar structure, etc. problem, to achieve the effect of no agglomeration, uniform surface modification, and no change in particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

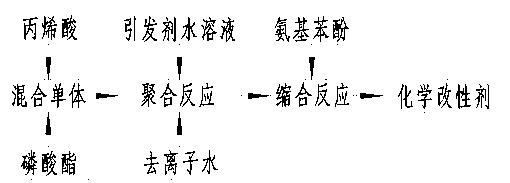

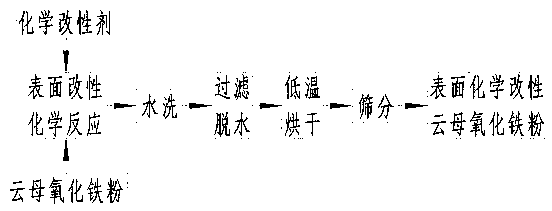

[0027] Such as figure 1 , figure 2 , image 3 Shown, a kind of surface chemically modified mica iron oxide powder and preparation method thereof, comprises the following steps:

[0028] Step 1. Synthesis of chemical modifiers

[0029] 1. Prepare the mixed monomer of acrylic acid and phosphoric acid ester, and prepare the aqueous initiator solution.

[0030] 2. Add 30% mixed monomer, 40% initiator aqueous solution, and deionized water into the reaction kettle with stirring and reflux condenser, heat to 80-85°C with a constant temperature water bath, and carry out solution polymerization for 0.5h.

[0031] 3. Add the remaining 70% of the mixed monomer and 60% of the initiator aqueous solution to the reaction kettle slowly and simultaneously, for 3-4 hours, while maintaining the temperature of the material at 80-85°C, and continue the solution polymerization reaction.

[0032] 4. After the dropwise addition of the mixed monomer and initiator aqueous solution is completed, ad...

Embodiment 1

[0042] Step 1. Synthesis of chemical modifiers

[0043] 1. Prepare 100 g of mixed monomer by mixing 70 g of acrylic acid and 30 g of methacrylic acid-β-hydroxyethyl phosphate, and prepare 40 g of ammonium persulfate initiator aqueous solution.

[0044] 2. Add 30g of mixed monomers, 16g of ammonium persulfate initiator aqueous solution, and 160g of deionized water into a 500ml reactor with stirring and reflux condenser, heat to 80°C with a constant temperature water bath, and carry out solution polymerization for 0.5h .

[0045] 3. Slowly add the remaining 70g of mixed monomer and 24g of ammonium persulfate initiator aqueous solution into a 500ml reaction kettle synchronously and slowly for 3 hours while maintaining the material temperature at 80°C to continue the solution polymerization reaction.

[0046] 4. After the aqueous solution of the mixed monomer and ammonium persulfate initiator is added dropwise, add 60 g of o-aminophenol into a 500 ml reaction kettle, and maintain...

Embodiment 2

[0054] Step 1. Synthesis of chemical modifiers

[0055] 1. Mix 90g of acrylic acid and 10g of methacrylic acid-β-hydroxyethyl phosphate to make 100g of mixed monomer, and prepare 40g of sodium persulfate initiator aqueous solution.

[0056] 2. Add 30g of mixed monomer, 16g of sodium persulfate initiator aqueous solution, and 160g of deionized water into a 500ml reactor with stirring and reflux condenser, heat it to 85°C with a constant temperature water bath, and carry out solution polymerization for 0.5h .

[0057] 3. Add the remaining 70g of mixed monomer and 24g of sodium persulfate initiator aqueous solution into a 500ml reaction kettle slowly and dropwise for 4 hours, while maintaining the temperature of the material at 85°C to continue the solution polymerization reaction.

[0058] 4. After the dropwise addition of the mixed monomer and sodium persulfate initiator aqueous solution, add 30 g of m-aminophenol into a 500 ml reaction kettle, and maintain the material temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com