7-phenylacetamide-3-deacetoxycephalosporanate and preparation method and application thereof

A technology of acetoxycephalosporanic acid salt and acetoxycephalosporanic acid, which is applied in the field of drug synthesis, can solve the problems of raw material drug quality impact, poor quality of 7-ADCA, etc., and achieve the effect of quality improvement and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

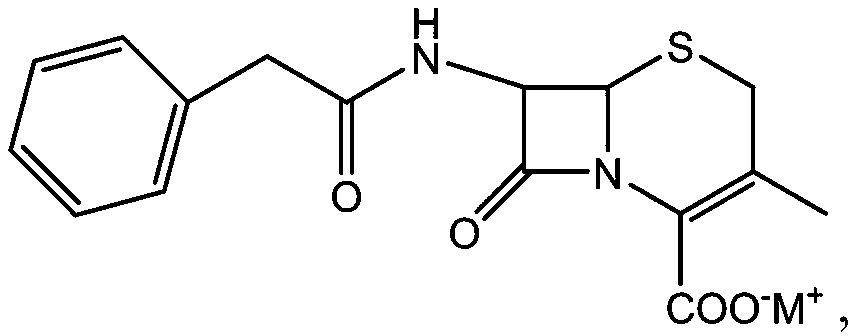

[0066] The preferred synthetic route for preparing high-content 7-ADCA of the present invention is as follows:

[0067]

[0068] In order to obtain the 7-ADCA of high content, the present invention takes preferred technical scheme and comprises the steps:

[0069] (1) Preparation of high-content 7-phenylacetamido-3-desacetoxycephalosporanic acid and salts thereof.

[0070] The crude product of 7-phenylacetamido-3-desacetoxycephalosporanic acid is salt-formed and crystallized to obtain high-purity 7-phenylacetamido-3-desacetoxycephalosporanic acid salt; Add 7-phenylacetamido-3-desacetoxycephalosporanic acid salt into water, adjust the pH to 1-3 with acid, crystallize, and obtain high content of 7-phenylacetamido-3-desacetoxycephalosporanic acid .

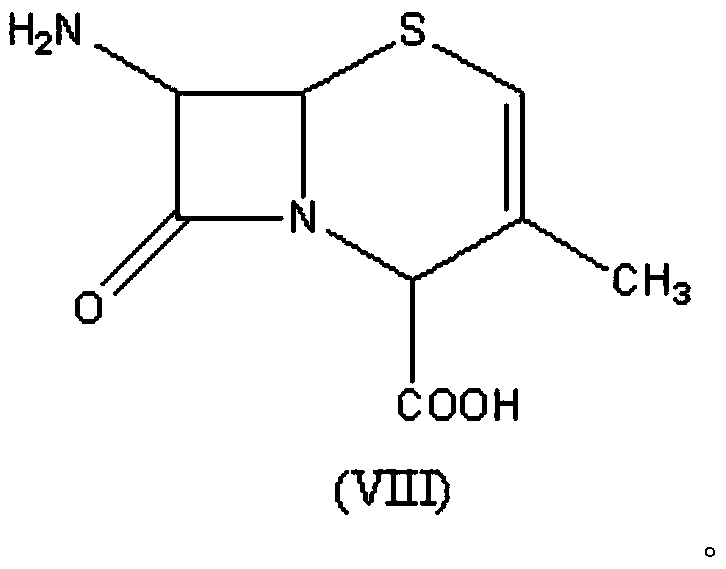

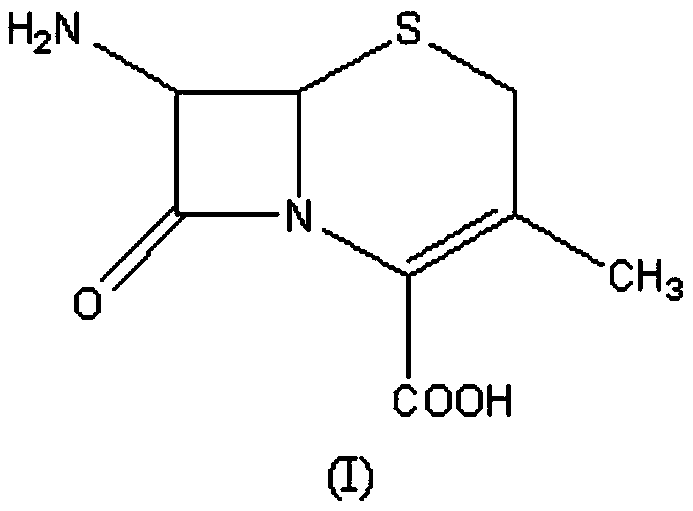

[0071] (2) Preparation of high content 7-ADCA

[0072] The high-purity 7-phenylacetamido-3-desacetoxycephalosporanic acid or its salt obtained in the above step (1) is catalyzed by penicillin acylase to obtain 7-ADCA lysate, an...

Embodiment 1

[0111] Add 20g of crude product of cyclohexanoic acid (content 95.3wt%) into a 500ml reaction bottle, add 40ml of deionized water, add 50ml of acetone (for dispersion, can reduce the amount of water), stir, and dropwise add about 4.2ml of 24wt% ammonia water , adjust the pH to 6.5-7.0, stir for 30 min, add dropwise 400 ml of acetone, cool down to 0-5°C, and stir for 30 min. Filter, wash with 50 ml of acetone, filter dry, and dry under reduced pressure to obtain 19.53 g of cycloexpanded acid ammonium salt (HPLC purity 99.8%), yield 97.5% (mol / mol).

[0112] Add 10 g of the prepared ammonium cyclocyclate salt to 100 ml of water, adjust the pH to 6-8 to dissolve, add 5 g of immobilized penicillin acylase (immobilized enzyme), keep warm at 28-32°C, and maintain pH 7.5-8.5 with ammonia water , until the cleavage reaction is complete, the immobilized enzyme is filtered off to obtain the enzymatic hydrolysis solution. The temperature of the enzymolysis solution was raised to 30-35° ...

Embodiment 2

[0114] Add 20g of the crude product of cyclohexanoic acid (content 95.3wt%) into a 500ml reaction bottle, add 100ml of absolute ethanol, stir to dissolve, add about 4.2ml of 24wt% ammonia water dropwise, adjust the pH to 6.5-7.0, stir for 30min, and then add dropwise Add 200ml of ethanol, cool down to 0-5°C, and stir for 30min. Filter, wash with 50 ml of absolute ethanol, filter dry, and dry under reduced pressure to obtain 19.45 g of cycloexpanded ammonium salt (HPLC purity 99.8%). Yield 97.1% (mol / mol).

[0115] Add 10 g of the prepared cycloexpandant ammonium salt into 100 ml of water, adjust the pH to 6 to 8 to dissolve, add 5 g of immobilized penicillin acylase (immobilized enzyme), keep warm at 28 to 32 ° C, and maintain it with 4 wt % sodium hydroxide aqueous solution. pH 7.5-8.5, until the cleavage reaction is complete, filter out the immobilized enzyme, and obtain the enzymatic hydrolysis solution. The temperature of the enzymolysis solution was raised to 30-35° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com