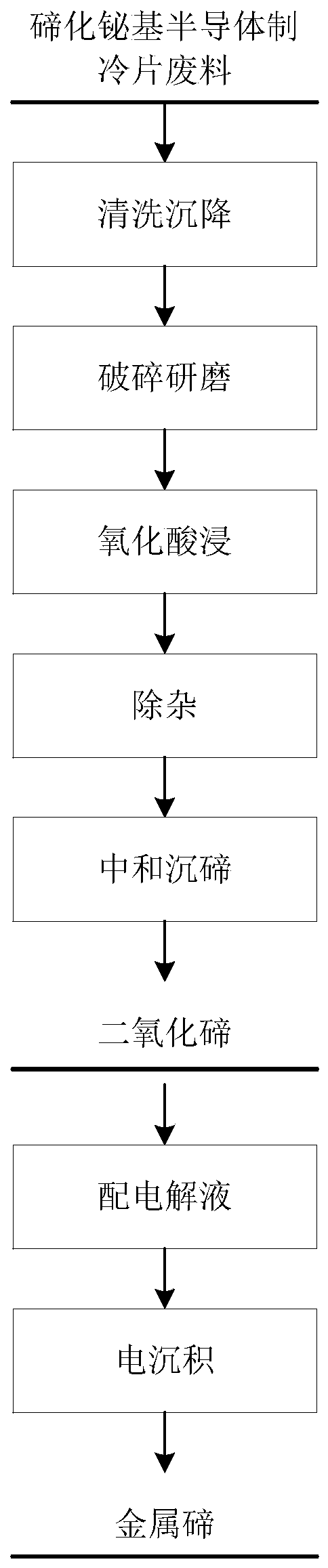

Method for recovering tellurium from bismuth telluride-based thermoelectric cooler wastes

A bismuth telluride-based and semiconductor technology is applied in the field of recycling tellurium, which can solve the problems of high energy consumption and large environmental impact, and achieve the effects of reducing energy consumption, strong applicability, and improved recycling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 130g of bismuth telluride-based semiconductor refrigeration sheet waste into 5wt% sodium hydroxide solution and soak for 8h at 50°C, stirring continuously in the middle, cleaning to remove organic impurities such as oil, filtering, crushing and grinding, to obtain a particle size of 0.1 mm tellurium-containing material powder.

[0030] (2) Prepare a hydrochloric acid solution with a concentration of 4mol / L, measure 520mL of the hydrochloric acid solution according to the solid-liquid mass volume ratio of 1:4, and add the tellurium-containing material powder and the hydrochloric acid solution into the reaction vessel.

[0031] (3) Raise the reaction temperature in step 2 to 80° C., slowly add sodium hypochlorite whose mass is twice the mass of tellurium metal, keep the reaction for 2 hours, filter, and collect the filtrate A.

[0032] (4) Raise the reaction temperature to 85° C., add sodium sulfite whose mass is 8 times the mass of selenium metal to the filtrate ...

Embodiment 2

[0036](1) Add 100g of bismuth telluride-based semiconductor refrigeration sheet waste into 2wt% sodium tetrapolypropylene benzene sulfonate and soak for 10h at 30°C, stirring continuously in the middle, cleaning to remove organic impurities such as oil, filtering, crushing and grinding, and obtaining the particle size It is 0.1mm tellurium-containing material powder.

[0037] (2) Prepare a hydrochloric acid solution with a concentration of 6mol / L, measure 500mL of the hydrochloric acid solution according to the solid-liquid mass volume ratio of 1:5, and add the tellurium-containing material powder and the hydrochloric acid solution into the reaction vessel.

[0038] (3) Raise the reaction temperature in step 2 to 60° C., slowly add sodium chlorate whose mass is 0.5 times the mass of tellurium metal, keep the reaction for 1 hour, filter, and collect the filtrate A.

[0039] (4) Raise the reaction temperature to 75° C., add hydroxylamine hydrochloride whose mass is 5 times that ...

Embodiment 3

[0043] (1) Add 160g of bismuth telluride-based semiconductor refrigeration chip waste into 8wt% sodium carbonate solution and soak at 60°C for 6 hours, stirring continuously in the middle, cleaning and removing organic impurities such as oil, filtering, crushing and grinding to obtain a particle size of 0.1mm containing Tellurium material powder.

[0044] (2) Prepare a hydrochloric acid solution with a concentration of 5 mol / L, measure 960 mL of the hydrochloric acid solution according to the solid-liquid mass volume ratio of 1:6, and add the tellurium-containing material powder and the hydrochloric acid solution into the reaction vessel.

[0045] (3) Raise the reaction temperature in step 2 to 70° C., slowly add calcium hypochlorite whose mass is 1 times the mass of tellurium metal, keep the reaction for 3 hours, filter, and collect the filtrate A.

[0046] (4) Raise the reaction temperature to 80° C., add hydrazine hydrate whose mass is 6 times the mass of selenium metal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com