An automatic sub-mesh grinding and collecting device for raw ore and its application method

A collection device and grinding technology, used in cleaning methods and utensils, chemical instruments and methods, grain processing, etc. Simple, easy to operate, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

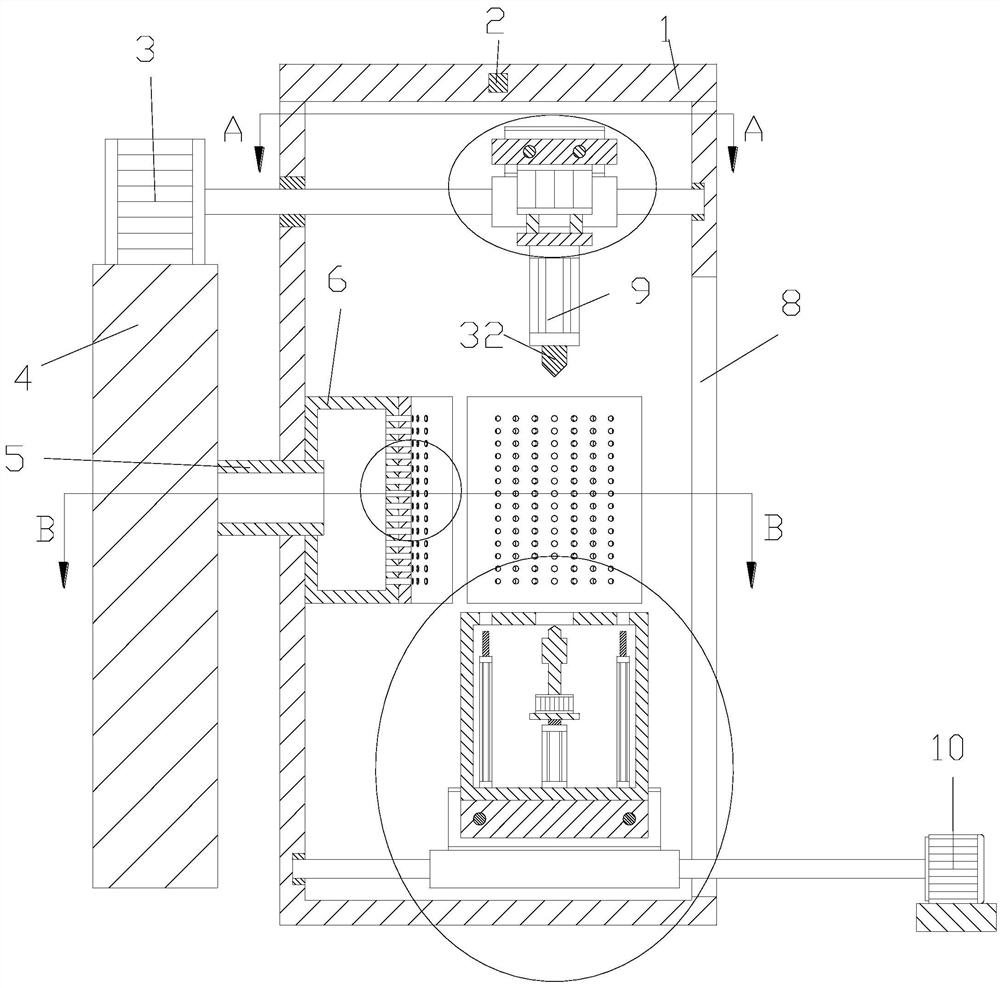

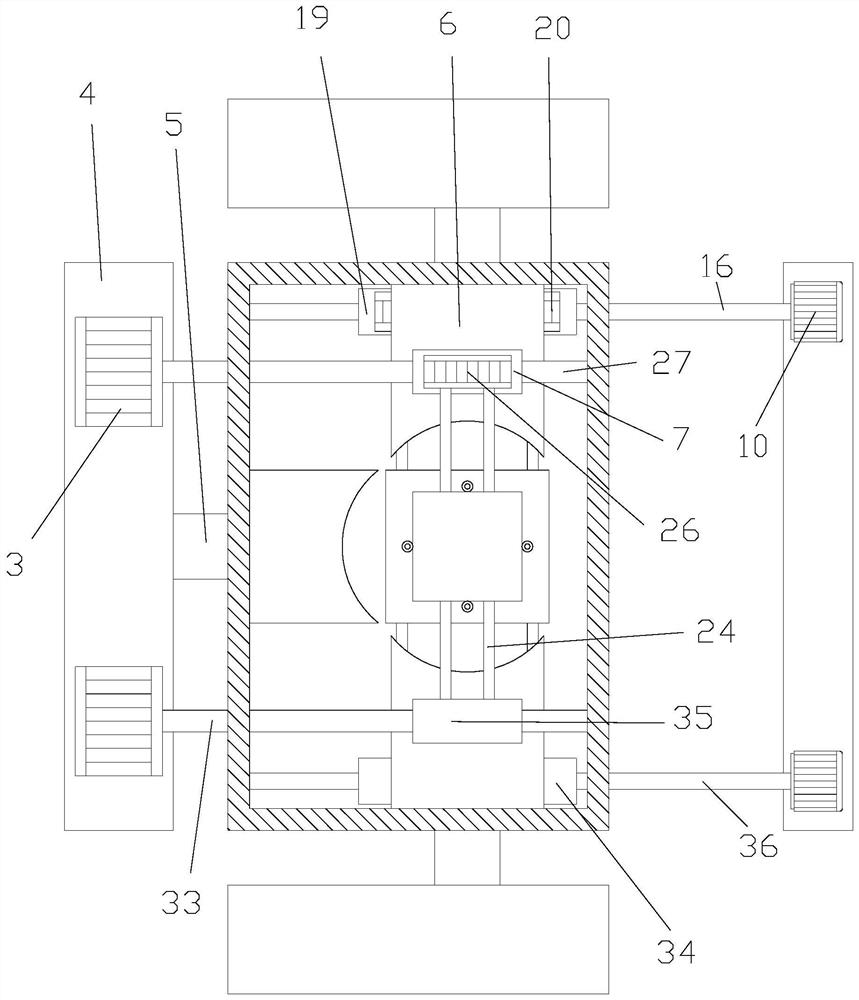

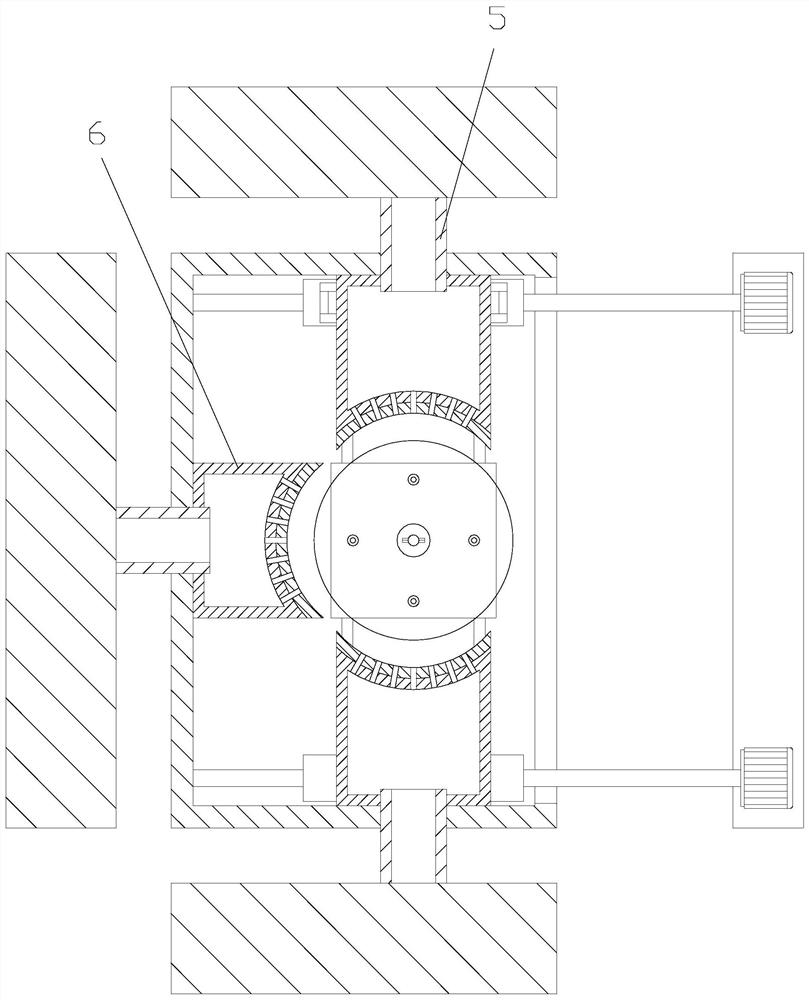

[0022] Refer to attached figure 1 , 2, 3, 4, 5, 6, 7, 8: In the present embodiment, this kind of automatic subhead grinding and collecting device for raw ore includes a box body 1, and the front, rear, left three sides of the box body 1 are provided with a vacuum cleaner 4 fixedly connected to the ground The front and rear ends on the right side of the box body 1 are provided with a motor one 10 fixedly connected to the ground, and the front half and the rear half of the top of the vacuum cleaner 4 on the left side are fixedly equipped with a motor two 3, and the box body 1 The inner wall of the right end is provided with an inlet and outlet 8 communicating with the outside world, and a dust collection box 6 is fixedly installed in the middle of the inner wall of the front, rear, left three ends of the box body 1, and a grinding layer 30 is fixedly installed at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com