Preparation method and application of highly crystalline carbon nitride photocatalytic material

A carbon nitride photocatalytic material technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve problems such as CCN crystallinity is not ideal, achieve enhanced photocatalytic hydrogen production activity, increase electronic Delocalized, effects suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

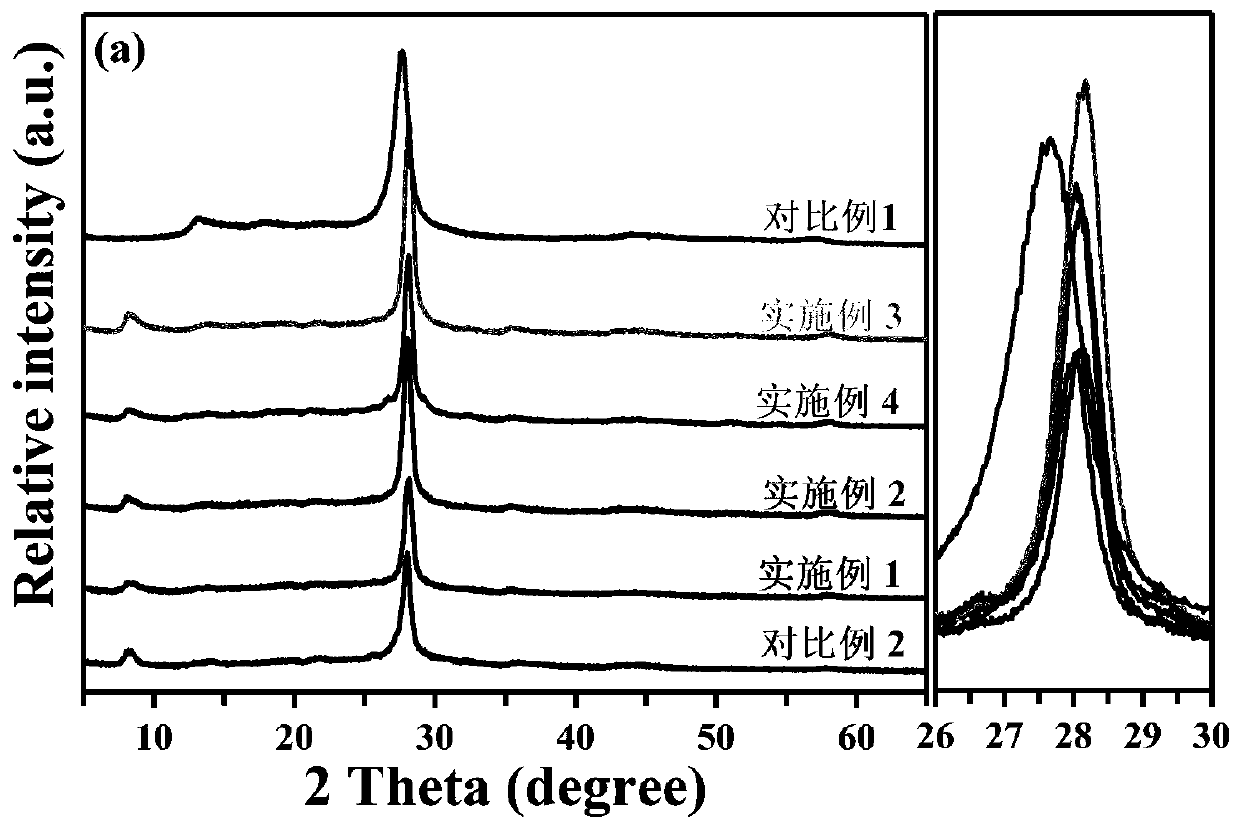

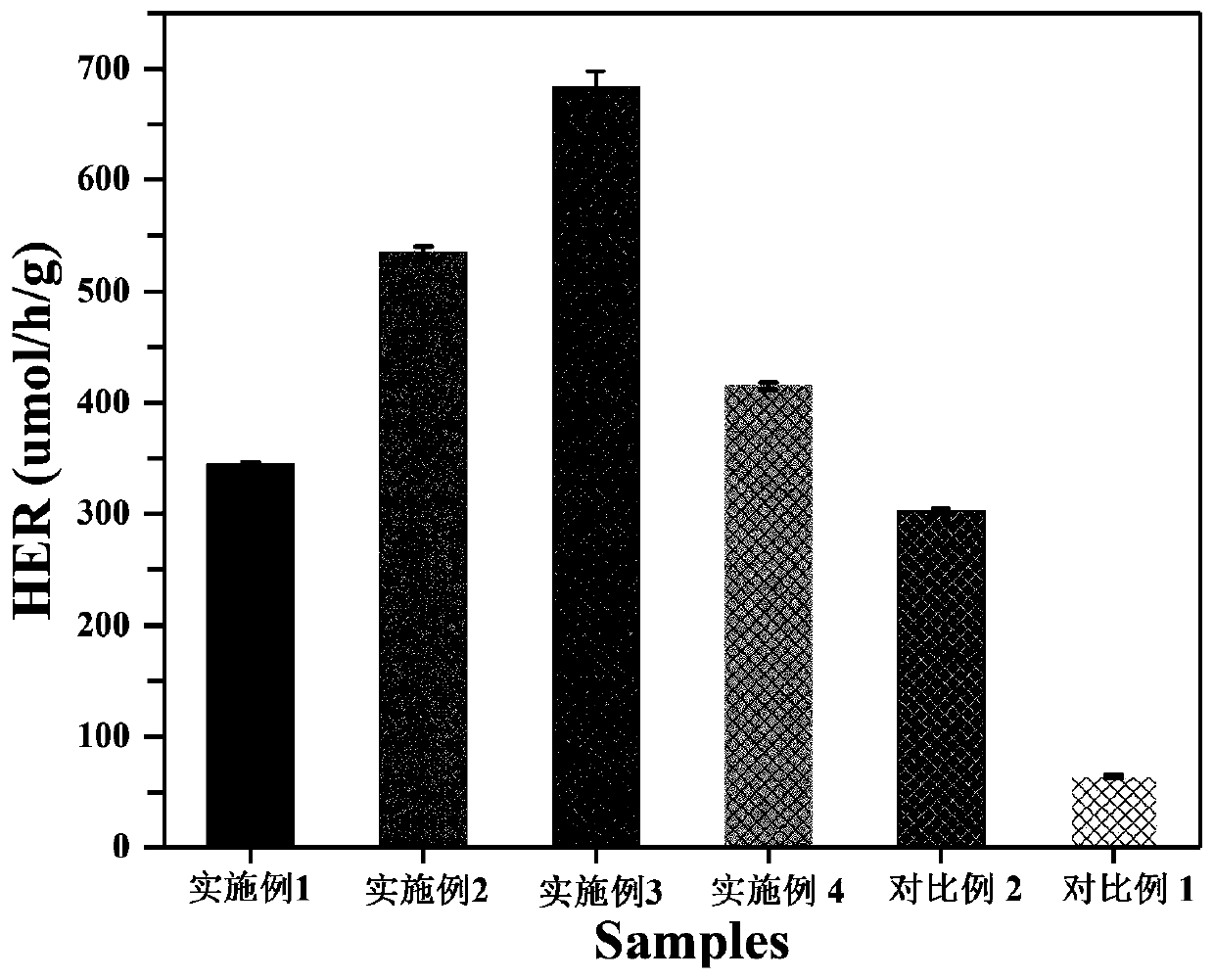

[0027] A preparation method of a highly crystalline carbon nitride photocatalytic material, specifically comprising the following steps:

[0028] Step 1. Preparation of the heptazine precursor: Weigh a certain amount of melamine in a semi-closed crucible and place it in a muffle furnace for calcination. After the calcination, cool naturally to room temperature to obtain the heptazine precursor;

[0029] Step 2, preparation of crystallized carbon nitride: Grind the heptazine precursor, potassium chloride and lithium chloride obtained in step 1 in a mortar, mix evenly, transfer the obtained mixture into a semi-closed crucible, and place Carry out calcination in a muffle furnace, after calcination, naturally cool to room temperature; the obtained product is washed with hot water and ethanol, dried to obtain crystallized carbon nitride; wherein, the mass ratio of heptazine precursor, potassium salt and lithium salt It is 1: (3~10): (3~10);

[0030] Step 3. Preparation of highly c...

Embodiment 1

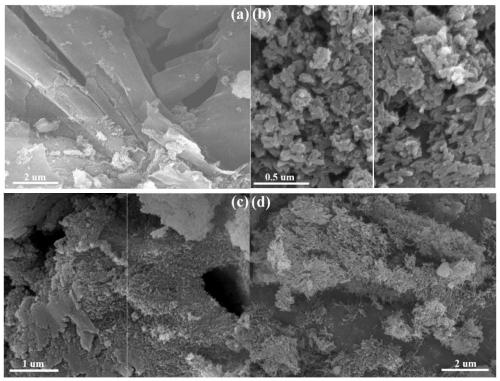

[0043] A method for preparing a highly crystalline carbon nitride photocatalytic material, comprising the steps of:

[0044](1) Preparation of the heptazine precursor: Weigh 5 g of melamine in a semi-closed crucible and place it in a muffle furnace for calcination at 500° C. for 4 hours. After the calcination, cool naturally to room temperature to obtain the heptazine precursor;

[0045] (2) Preparation of crystallized carbon nitride: first, weigh 0.6g of the heptazine precursor prepared in step (1), 3.3g of potassium chloride and 2.7g of lithium chloride and grind and mix them uniformly in a mortar; then Transfer the mixture into a semi-closed crucible, and place it in a muffle furnace for calcination at 550°C for 4 hours. After the calcination, it is naturally cooled to room temperature and taken out; the obtained product is washed with hot water at 85°C and ethanol in sequence, and dried to obtain The crystallized carbon nitride;

[0046] (3) Preparation of highly crystall...

Embodiment 2

[0048] Compared with Example 1, this example differs in that: the concentration of the aqueous hydrochloric acid solution in step (3) is 0.01mol / L; the rest of the steps are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com