Silicon deoxidizing process for silicon-contained steel grades

A technology of silicon steel and process, which is applied in the field of silicon deoxidation process, can solve the problems of high deoxidation cost and inclusion of aluminum and iron, and achieve the effect of reducing the probability of water blocking and no downflow, low cost and good deoxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

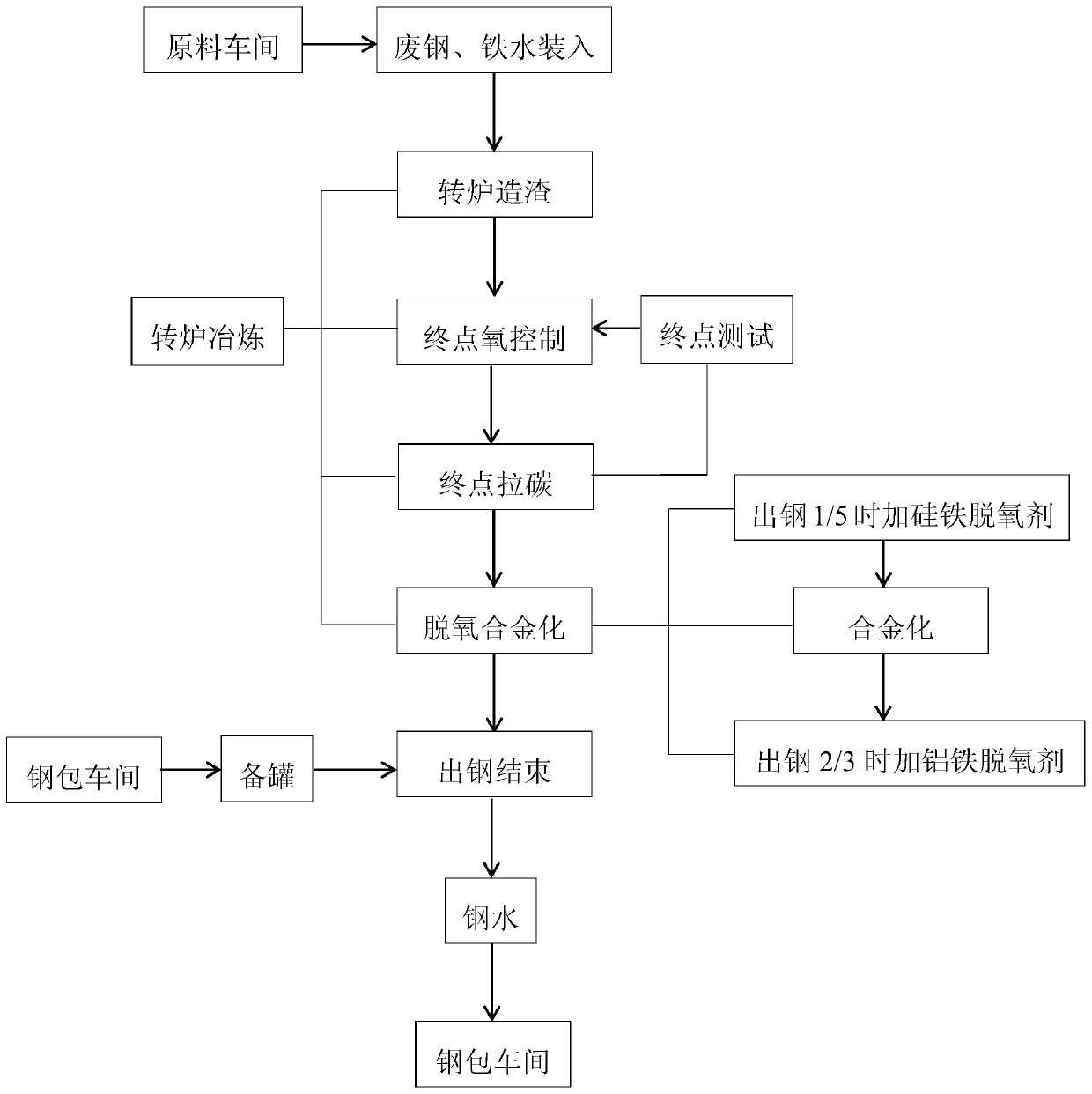

Method used

Image

Examples

Embodiment 1

[0024] Aiming at 175-ton converter smelting, a silicon deoxidation process for silicon-containing steel includes the following steps:

[0025] In terms of mass fraction, the silicon content in steel is required to be 0.12%. Add 100kg of ferrosilicon deoxidizer when 1 / 5 of the converter is tapped, then add ferromanganese alloy and recarburizer in turn, and finally add aluminum when 2 / 3 of the converter is tapped Iron deoxidizer 100kg;

[0026] After the molten steel enters the LF furnace, the first slagging and desulfurization operation is carried out. When the S content before argon meets the standard, the amount of slagging aluminum added is 68kg; after the first slagging and desulfurization, the S content and the color of the slag All meet the regulatory requirements.

Embodiment 2

[0028] Aiming at 175-ton converter smelting, a silicon deoxidation process for silicon-containing steel includes the following steps:

[0029] In terms of mass fraction, the content of silicon in steel is required to be 0.08%, and the content of manganese is less than 1.00%. Add 30kg of ferrosilicon deoxidizer when 1 / 5 of the converter is tapped, and then add ferromanganese alloy and recarburizer in turn. Add 200kg of aluminum iron deoxidizer when steel 2 / 3;

[0030] After the molten steel enters the LF furnace treatment position, the first slagging and desulfurization operation is carried out. When the S content before argon meets the standard, the amount of slagging aluminum is 65kg; after the first slagging and desulfurization, the S content does not meet the regulations It is required that the refining performs the second slagging and desulfurization operation, the color of steel slag is white and green, the amount of aluminum added for the second slagging is 10kg, and after th...

Embodiment 3

[0032] Aiming at 175-ton converter smelting, a silicon deoxidation process for silicon-containing steel includes the following steps:

[0033] In terms of mass fraction, the silicon content in the steel is required to be 0.10%, and the manganese content is less than 1.00%. Add 30kg of ferrosilicon deoxidizer when 1 / 5 of the converter is tapped, and then add ferromanganese alloy and recarburizer in turn. Add 250kg of aluminum-iron deoxidizer for steel 2 / 3; after molten steel enters the LF furnace treatment position, perform the first slagging and desulfurization operation. When the S content before argon meets the standard, the amount of slagging aluminum added is 63kg; After the completion of the secondary slagging and desulfurization, the S content does not meet the requirements of the regulations. The refining performs the second slagging and desulfurization operation. The color of the steel slag is dark green. The amount of aluminum added in the second slagging is 30kg. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com