Flexible organic package composition and preparing and use method thereof

A composition and organic technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as cracking or falling off, and achieve the effects of easy operation, high product purity, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

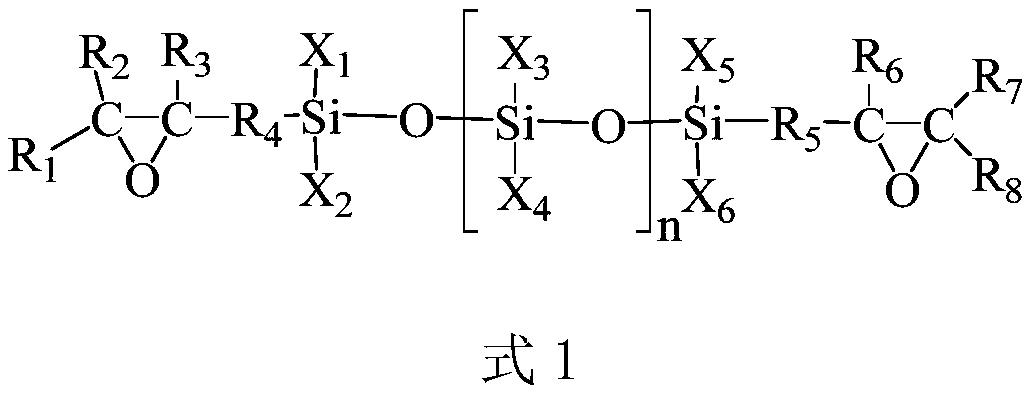

Image

Examples

preparation example Construction

[0041] The preparation method of the composition of the flexible organic package of the present invention is: according to the mass percentage, in a brown glass container, add silicon-based epoxy active monomer, acrylate active monomer, diluent, photoinitiator and auxiliary agent, and then After shaking and mixing at room temperature for 2 hours, the composition for encapsulation was obtained.

[0042] The use method of the composition of the flexible organic package of the present invention is: firstly, the composition of the flexible organic package is uniformly attached on the required surface by flash evaporation, inkjet printing, deposition, screen printing, spin coating or doctor blade coating. The encapsulated device surface is then irradiated by UV to promote the formation of an organic encapsulation film.

[0043] The present invention also proposes a preparation method of more than one component-silicon-based epoxy A: prepare 100 parts of vinyl epoxy, 10-50 parts of ...

Embodiment a

[0049] The preparation method of the silicon-based epoxy A of the present embodiment may further comprise the steps:

[0050] 1a) Weigh the hydrogen-containing siloxane and solvent into the beaker, stir it with a glass rod to make it evenly mixed, then blow nitrogen into it for 5-10 minutes, and finally add it into the three-necked flask, and carry out under nitrogen atmosphere Constant temperature magnetic stirring;

[0051] 2a) Then weigh the vinyl epoxy monomer and the catalyst, mix them uniformly and drop them into the solution in 1a), the dropping time is 20-40min;

[0052] 3a) After the dropwise addition reaction is completed, the reaction temperature is raised, and stirred under constant temperature reflux under a nitrogen atmosphere. After the reaction is completed, a solvent removal treatment is performed to obtain a light yellow viscous liquid.

[0053] Wherein, the mass ratio of vinyl epoxy, hydrogen-containing siloxane, catalyst and solvent is 100:20:3:150.

[00...

Embodiment b

[0059] The preparation method of silicon-based epoxy A of the present embodiment comprises the following steps:

[0060] 1a) Weigh the hydrogen-containing siloxane and solvent into the beaker, stir it with a glass rod to make it evenly mixed, then blow nitrogen into it for 5-10 minutes, and finally add it into the three-necked flask, and carry out under nitrogen atmosphere Constant temperature magnetic stirring;

[0061] 2a) Then weigh the vinyl epoxy monomer and the catalyst, mix them uniformly and drop them into the solution in 1a), the dropping time is 20-40min;

[0062] 3a) After the dropwise addition reaction is completed, the reaction temperature is raised, and stirred under constant temperature reflux under a nitrogen atmosphere. After the reaction is completed, a solvent removal treatment is performed to obtain a light yellow viscous liquid.

[0063] Wherein, the mass ratio of vinyl epoxy, hydrogen-containing siloxane, catalyst and solvent is 100:30:4:250.

[0064] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com