A kind of palm oil-based polyurethane porous material and preparation method thereof

A technology of porous material and palm oil, applied in the field of palm oil-based polyurethane porous material and palm oil-based polyurethane porous material preparation, can solve problems such as large environmental pollution, reduce environmental pollution, ensure sound absorption performance and compression performance, and improve the Effects of low frequency sound absorption and compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

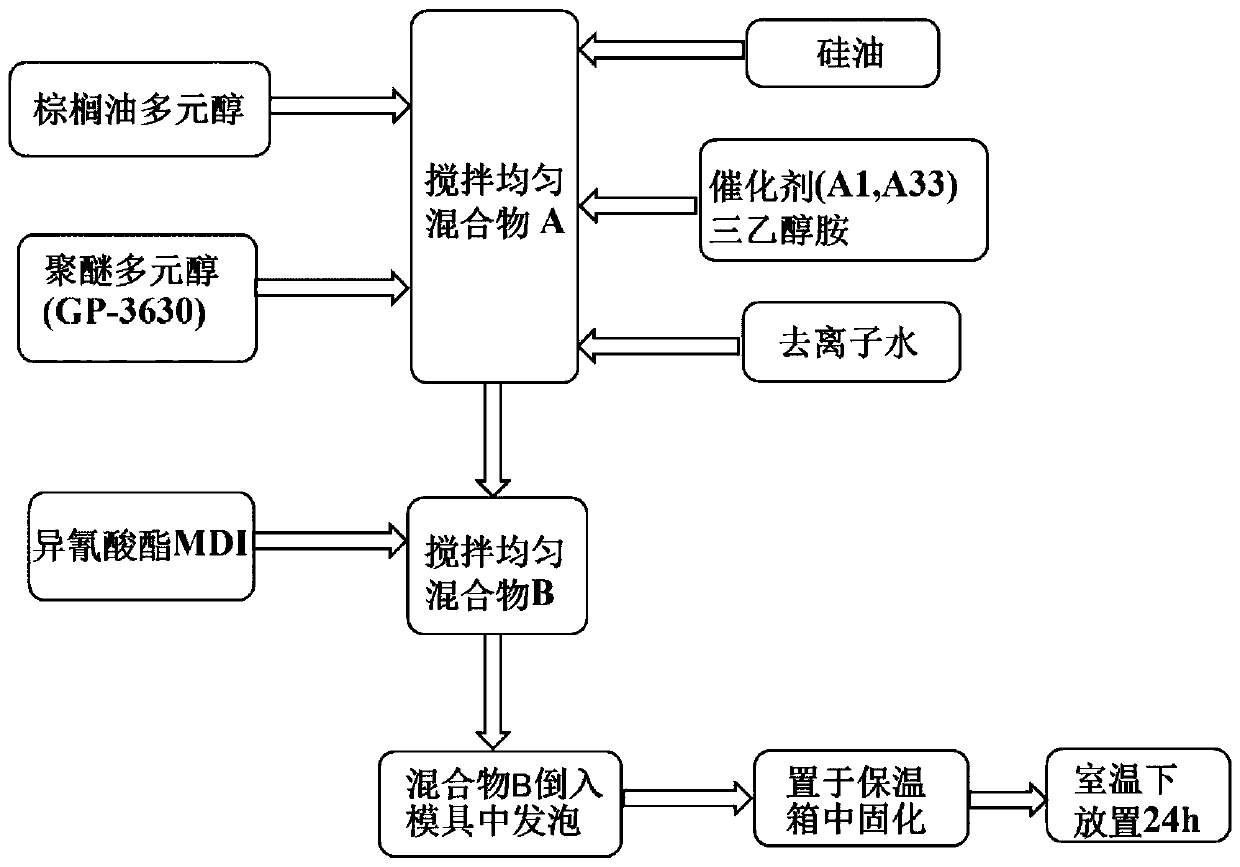

[0036] like figure 1 Shown, a kind of palm oil based polyurethane porous material preparation method comprises the steps:

[0037] Step 1, take the following raw materials according to the mass fraction:

[0038] Palm oil polyol: 43-49 parts, polyether polyol: 51-57 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.05 parts, catalyst A33: 1.0 parts, deionized water: 2.5 parts share;

[0039] Wherein, the hydroxyl value scope of described palm oil polyol is 170~200mg KOH / g;

[0040] Step 2, adding the raw material into the stirring device, and 1 Stir to prepare mixture A, and let it stand for 3 to 5 minutes; wherein, the speed n 1 =1500rpm;

[0041] Step 3, add 30 to 35 parts of polymerized MDI, and 2 Stir to obtain mixture B, speed n 2 =1300rpm;

[0042] Step 4: Pour the mixture B into the mold for free foaming, put it into the incubator for curing for 2 hours, and set the temperature of the incubator to 50°C.

[0043] Step 5. After standin...

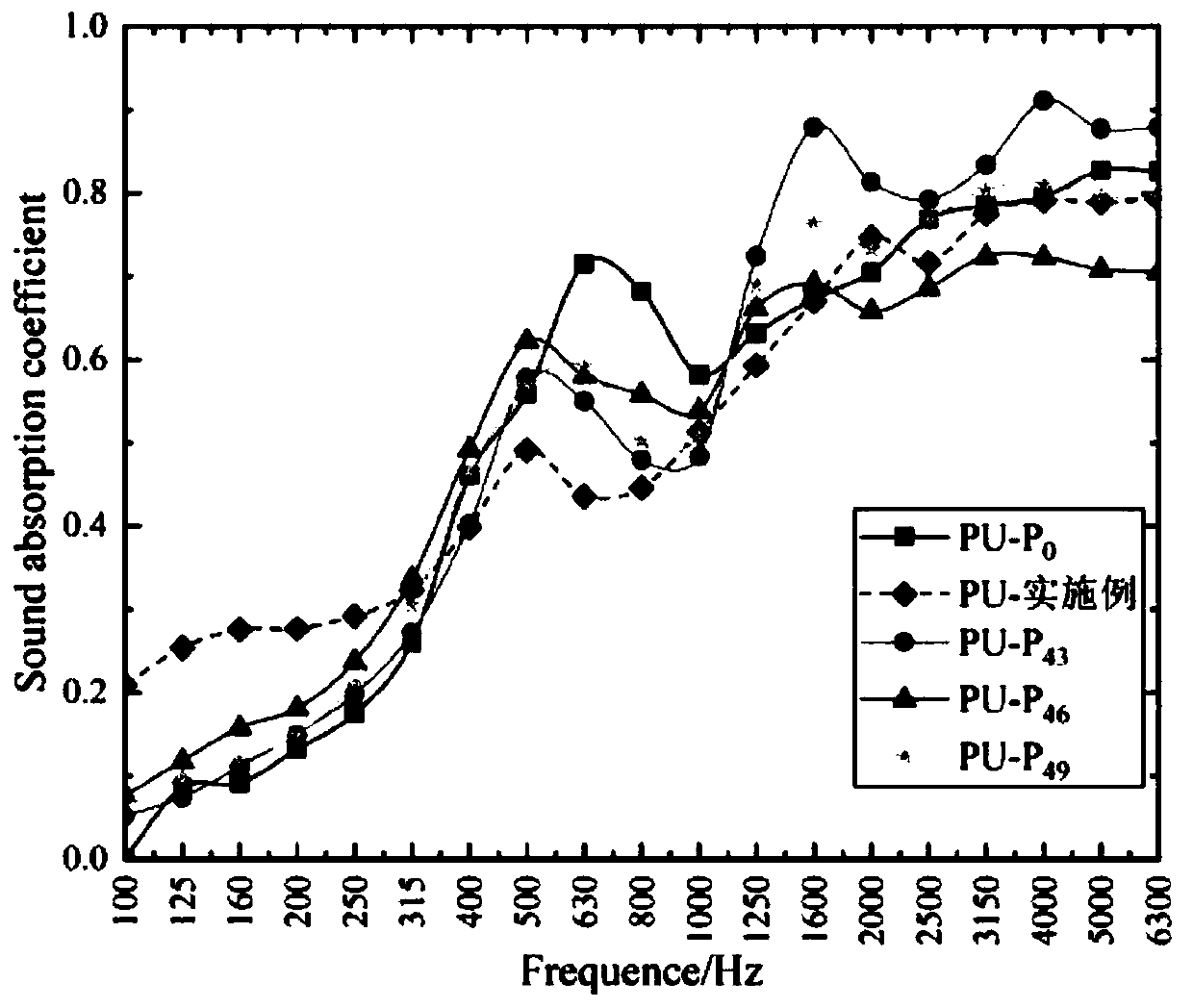

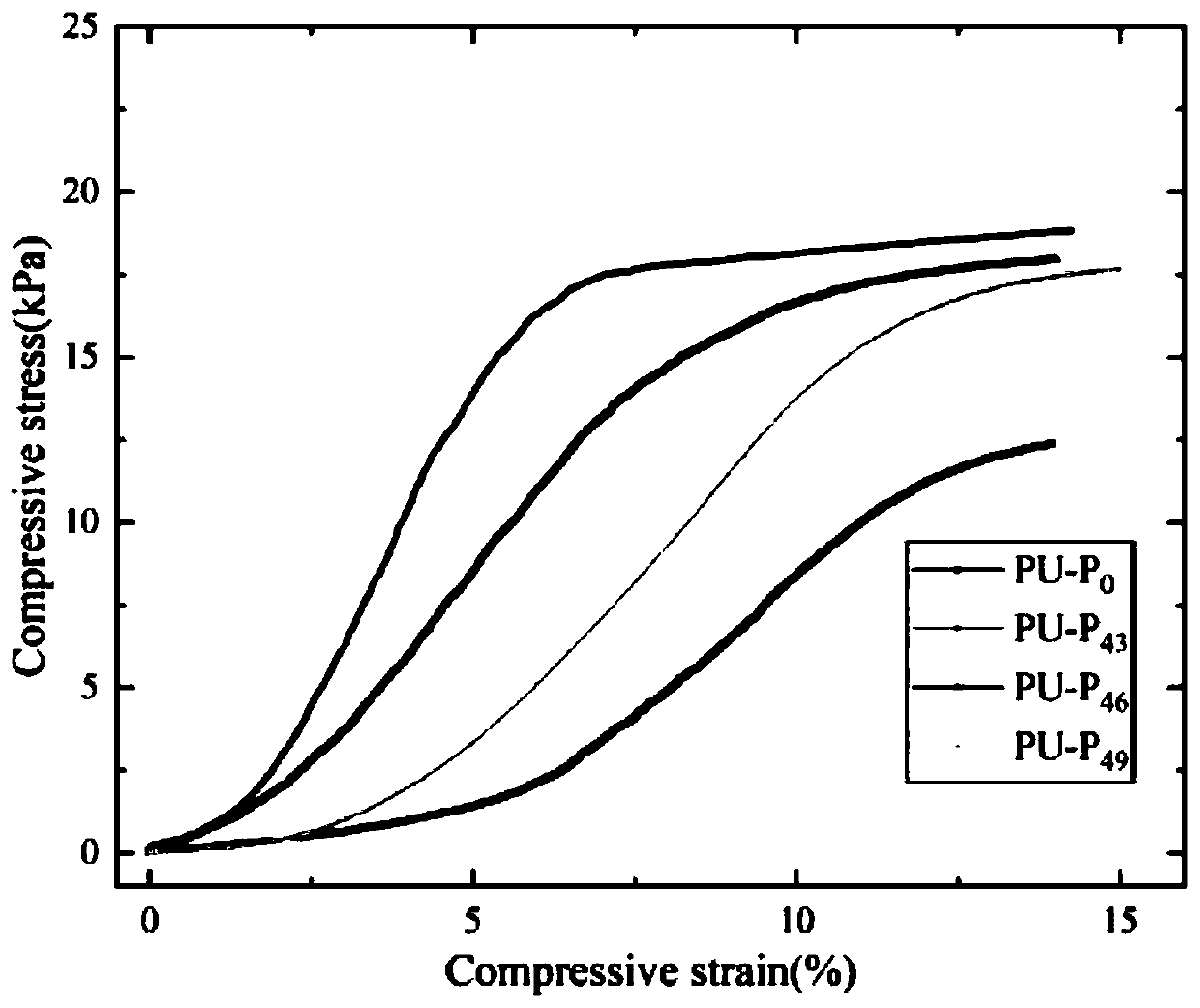

experiment example 1

[0045] Step 1, take the following raw materials according to the mass fraction:

[0046] Palm oil polyol: 43 parts, polyether polyol: 57 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.05 parts, catalyst A33: 1.0 parts, water: 2.5 parts;

[0047] Wherein, the hydroxyl value scope of described palm oil polyol is 170~200mg KOH / g;

[0048] Step 2. Add the raw materials into the stirring device, and 1 =1500rpm is stirred, and mixture A is obtained, and left standstill;

[0049] Step 3, add 30 to 35 parts of polymerized MDI, and 2 =1300rpm is stirred, obtains mixture B;

[0050] Step 4. Pour the mixture B into the mold for free foaming, and put it into an incubator for curing. The temperature of the incubator is set at 50°C.

experiment example 2

[0052] Step 1, take the following raw materials according to the mass fraction:

[0053] Palm oil polyol: 46 parts, polyether polyol: 54 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.05 parts, catalyst A33: 1.0 parts, water: 2.5 parts;

[0054] Wherein, the hydroxyl value scope of described palm oil polyol is 170~200mg KOH / g;

[0055] Step 2. Add the raw materials into the stirring device, and 1 =1500rpm is stirred, and mixture A is obtained, and left standstill;

[0056] Step 3, add 30 to 35 parts of polymerized MDI, and 2 =1300rpm is stirred, obtains mixture B;

[0057] Step 4. Pour the mixture B into the mold for free foaming, and put it into an incubator for curing. The temperature of the incubator is set at 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com