Treatment system for electroplating wastewater

A treatment system and technology for electroplating wastewater, applied in the fields of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of surface water, soil pollution, complex electroplating wastewater quality, environmental pollution, etc., to improve treatment efficiency , Improve the quality of electroplating wastewater treatment, improve the effect of treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The electroplating wastewater treatment system will be further described with reference to the accompanying drawings.

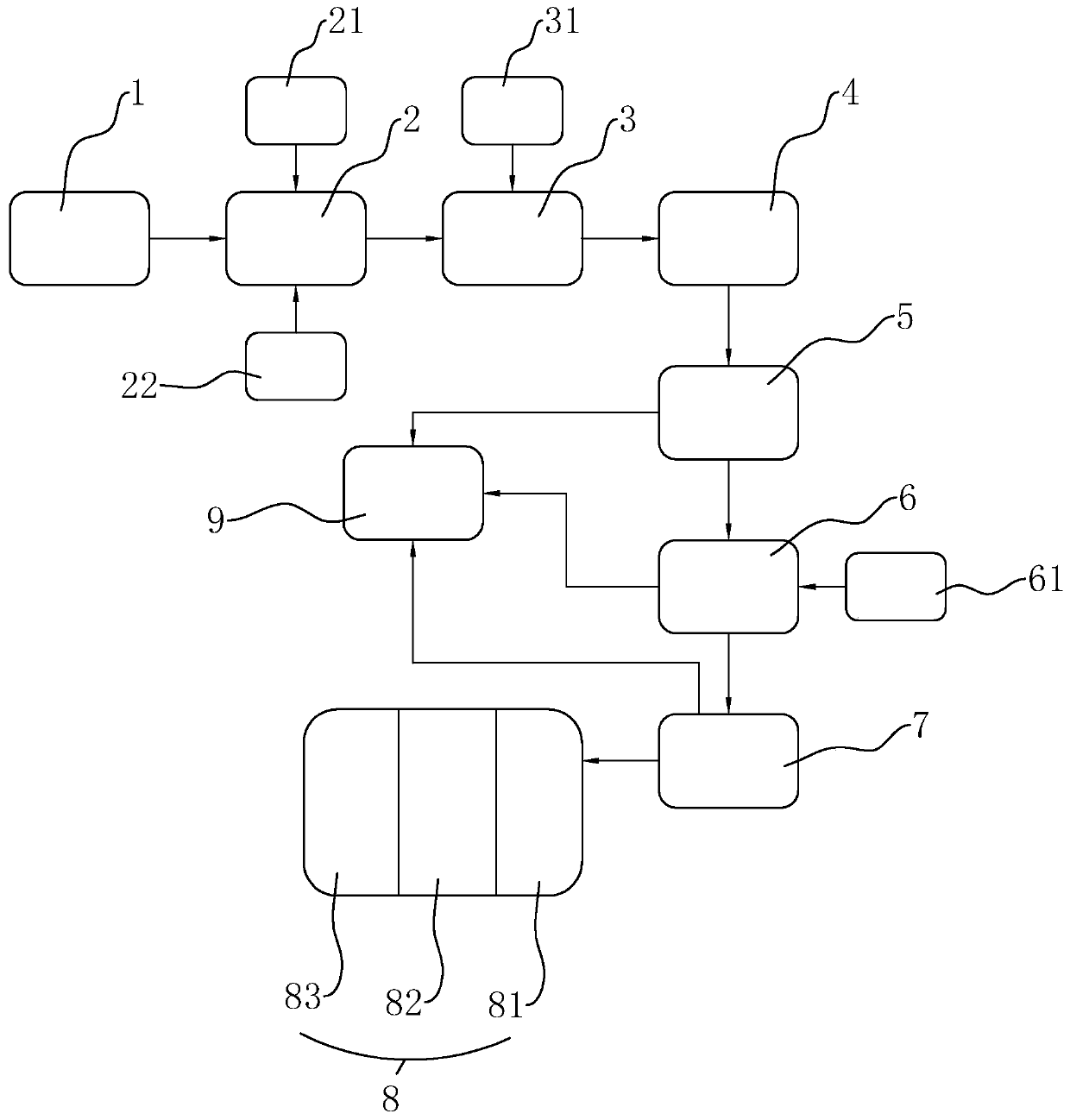

[0036] An electroplating wastewater treatment system, such as figure 1As shown, it includes natural sedimentation tank 1, chromium breaking reaction tank 2, neutralization reaction tank 3, flocculation tank 4, first flocculation sedimentation tank 5, electrolysis tower 6, second flocculation sedimentation tank 7 and comprehensive filtration device 8 connected in sequence , and the sludge outlets of the natural sedimentation tank 1, the first flocculation sedimentation tank 5, the electrolysis tower 6, and the second flocculation sedimentation tank 7 are all connected to a sludge compression device 9 to realize the compression treatment process of the sedimentation sludge.

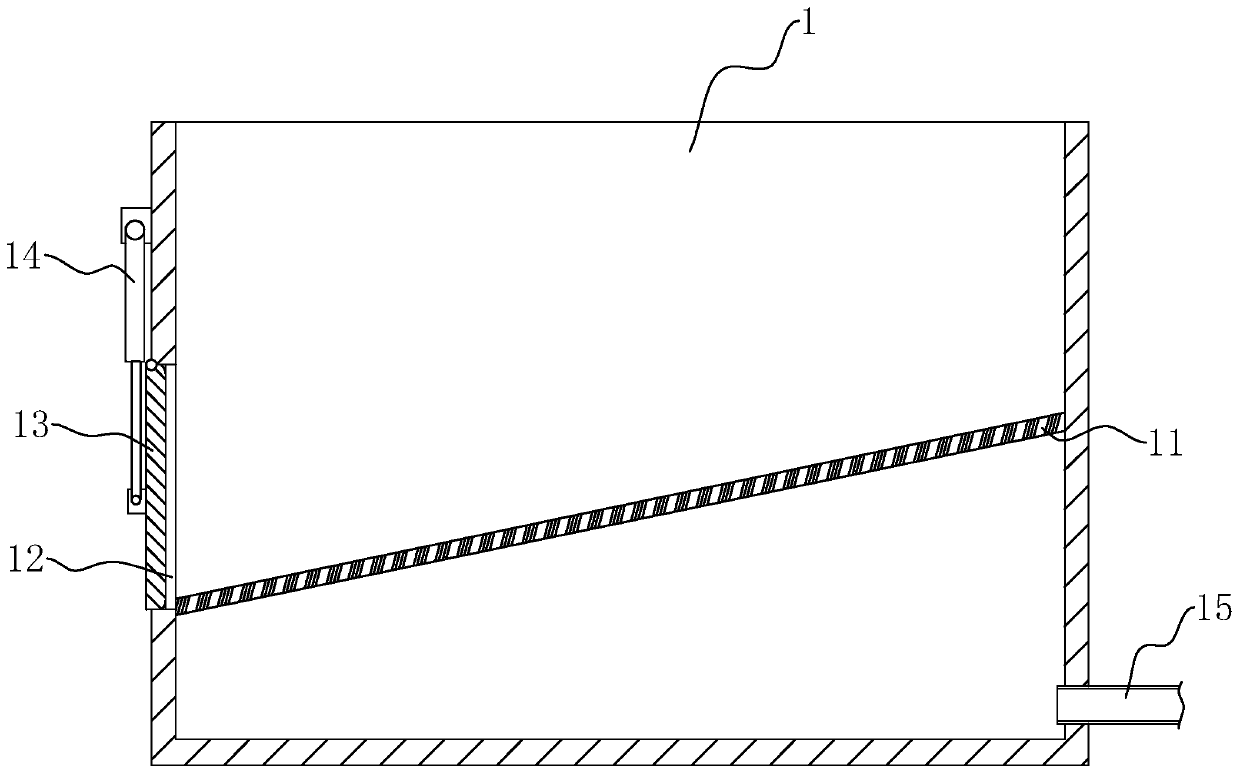

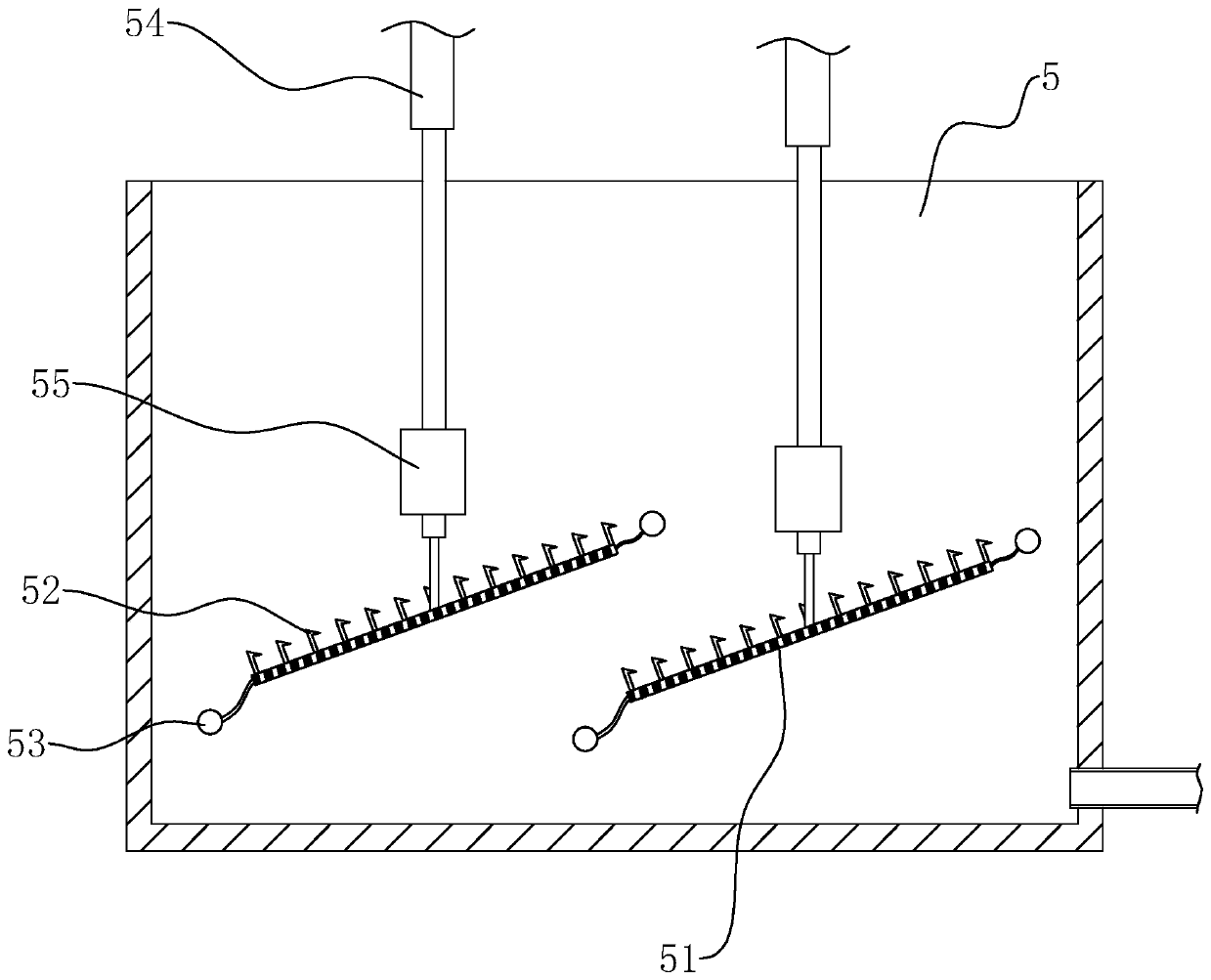

[0037] Such as figure 2 As shown, wherein, in the natural sedimentation tank 1, a filter fine grid 11 is obliquely arranged, and on the side wall of the natural sedimentation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com