Magnetic cyclodextrin-based crosslinked polymer adsorption material and preparation method thereof

A cross-linked polymer and adsorption material technology, which is applied in the field of magnetic cyclodextrin-based cross-linked polymer adsorption materials and its preparation, can solve the problems of complex treatment process, complex wastewater composition, and failure, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

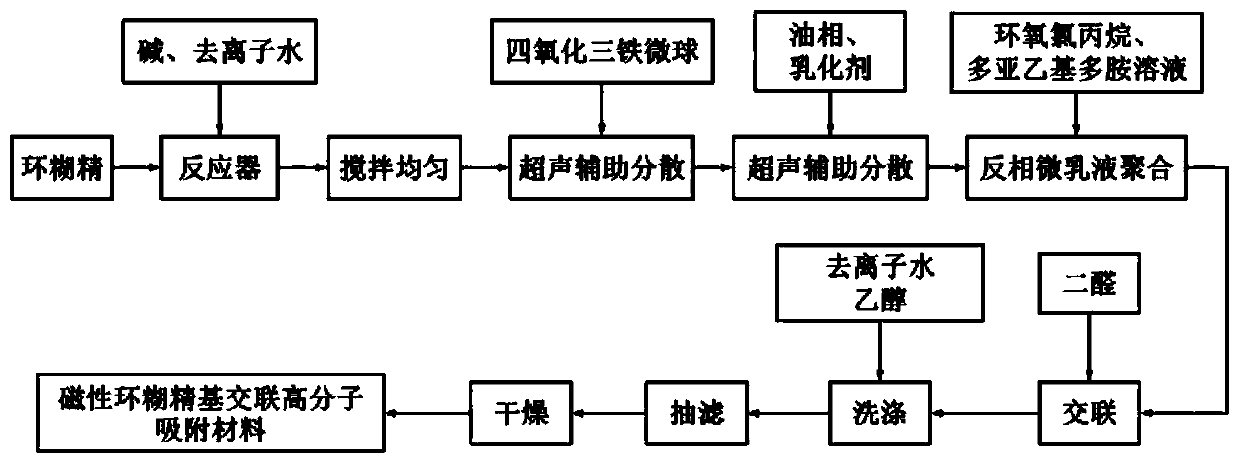

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 5.54 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensing device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 15%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:30, and 1.08 g of sodium hydroxide with a mass fraction of 96% is added to a three-necked flask for dissolution ;

[0035] (2) Add 0.50 g of ferric oxide microspheres into the solution in step (1) according to the mass ratio of β-cyclodextrin and ferric oxide microspheres to 1:0.5, and ultrasonically assisted stirring for 30 min;

[0036] (3) Add 22.18mL of liquid paraffin and 1.48g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:4, the mass volume ratio of the emulsifier to the oil phase is 1:15g / mL, and ultrasonic After auxiliary stirring for 30 minut...

Embodiment 2

[0039] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 3.91 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensation device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 20%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:40, and 1.44g of mass fraction of 96% sodium hydroxide is added to a three-necked flask for dissolution ;

[0040] (2) Add 1.00 g of ferric oxide microspheres into the solution of step (1) according to the mass ratio of β-cyclodextrin and ferric oxide microspheres as 1:1, and ultrasonically assist stirring for 40 min;

[0041] (3) Add 23.45mL of liquid paraffin and 1.56g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:6, the mass volume ratio of the emulsifier to the oil phase is 1:15g / mL, and ultrasonic After auxiliary stirring for 30 minutes, the te...

Embodiment 3

[0044] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 3.91 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensation device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 20%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:50, and 1.80 g of sodium hydroxide with a mass fraction of 96% is added to a three-necked flask for dissolution ;

[0045] (2) Add 1.50 g of ferric oxide microspheres into the solution in step (1) according to the mass ratio of β-cyclodextrin and ferric oxide microspheres to 1:1.5, and ultrasonically assisted stirring for 60 min;

[0046] (3) Add 31.26mL of liquid paraffin and 1.56g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:8, the mass volume ratio of the emulsifier to the oil phase is 1:20g / mL, and ultrasonic After auxiliary stirring for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com