Method for carrying out half-in-site observation on initiation position of point corrosion pit

An in-situ, pitting corrosion technology, applied in the field of austenitic-ferritic duplex stainless steel, can solve the problems of unclear G-phase and α effects, inability to determine the location of nano-scale pitting pit initiation, etc. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

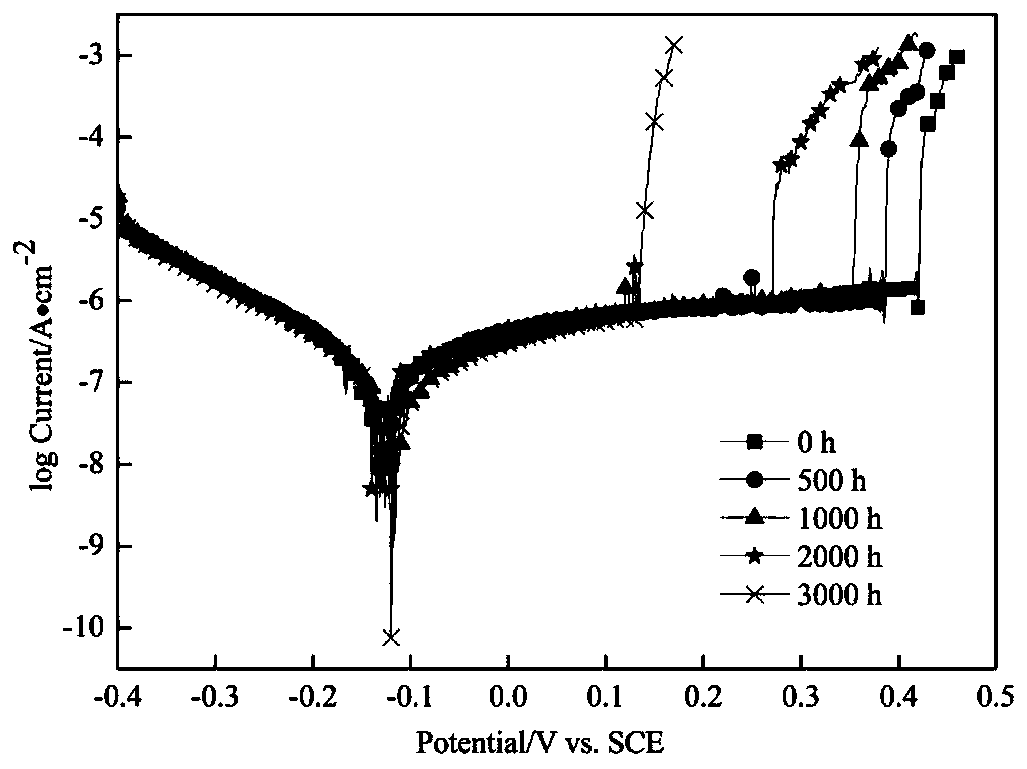

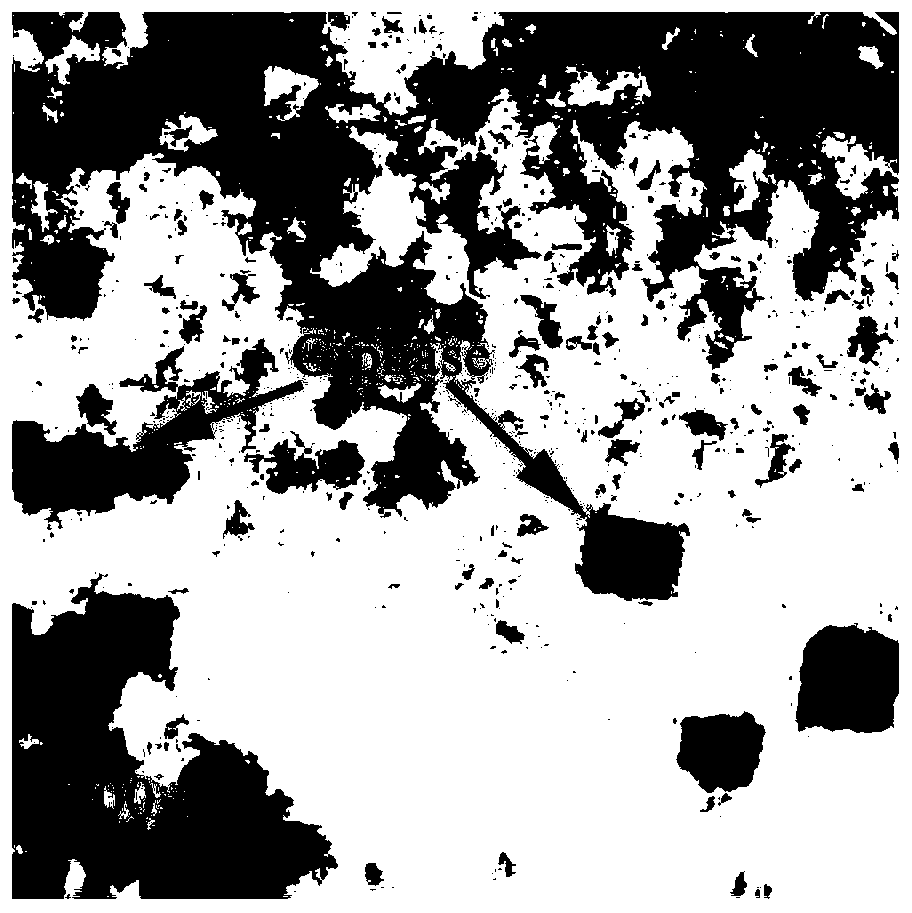

[0031] The Z3CN20.09M stainless steel heat-aged at 475°C for 2000 hours was cut into 15mm×15mm×5mm specimens, which were ground and polished. Put in 6wt.% FeCl at 35°C 3 After soaking in acid solution for 24 hours, the samples were taken out and subjected to ultrasonic pickling treatment immediately, and the corrosion morphology was observed under a metallographic microscope. It can be seen that the location of corrosion is mainly concentrated in the ferrite.

[0032] Cut the Z3CN20.09M stainless steel sample heat-aged at 475°C for 2000 hours into 0.5mm thick slices, grind it with 600#, 1200#, 2000# metallographic sandpaper in turn to 60-100μm and punch into a 3mm diameter disc. Then use 2000# metallographic sandpaper to polish to below 50μm thickness. The polished sample was initially thinned in an electrolytic double-spray apparatus, and the electrolyte was 95% ethanol + 5% perchloric acid, and then the ion thinning apparatus was used to finally thin it into a transmission...

Embodiment 2

[0038] The Z3CN20.09M stainless steel heat-aged at 475°C for 2000 hours was cut into 15mm×15mm×5mm specimens, which were ground and polished. Put in 6wt.% FeCl at 35°C 3 After soaking in acid solution for 24 hours, the samples were taken out and subjected to ultrasonic pickling treatment immediately, and the corrosion morphology was observed under a metallographic microscope. It can be seen that the location of corrosion is mainly concentrated in the ferrite.

[0039] Cut the Z3CN20.09M stainless steel sample heat-aged at 475°C for 2000 hours into 0.5mm thick slices, grind them to 60-100μm with 600#, 1200#, and 2000# metallographic sandpaper in turn, and punch them into discs with a diameter of 3mm. Then use 2000# metallographic sandpaper to polish to below 50μm thickness. The polished sample was initially thinned in an electrolytic double-spray apparatus, and the electrolyte was 95% ethanol + 5% perchloric acid, and then the ion thinning apparatus was used to finally thin i...

Embodiment 3

[0045]The Z3CN20.09M stainless steel heat-aged at 475°C for 3000 hours was cut into 15mm×15mm×5mm specimens, which were ground and polished. Put in 6wt.% FeCl at 35°C 3 After soaking in acid solution for 24 hours, the samples were taken out and subjected to ultrasonic pickling treatment immediately, and the corrosion morphology was observed under a metallographic microscope. It can be seen that the location of corrosion is mainly concentrated in the ferrite.

[0046] The Z3CN20.09M stainless steel sample that was heat-aged at 475°C for 3000 hours was cut into 0.5mm thick slices, polished with 600#, 1200#, 2000# metallographic sandpaper to 60-100μm in turn and punched into a 3mm diameter disc. Then use 2000# metallographic sandpaper to polish to below 50μm thickness. The polished sample was initially thinned in an electrolytic double-spray apparatus, and the electrolyte was 95% ethanol + 5% perchloric acid, and then the ion thinning apparatus was used to finally thin it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com