A refined simulation device and method for gas variable negative pressure drainage system

A simulation device and negative pressure technology, which is applied in the field of fine simulation device of gas variable negative pressure drainage system, can solve problems such as limiting the extraction efficiency of drainage holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

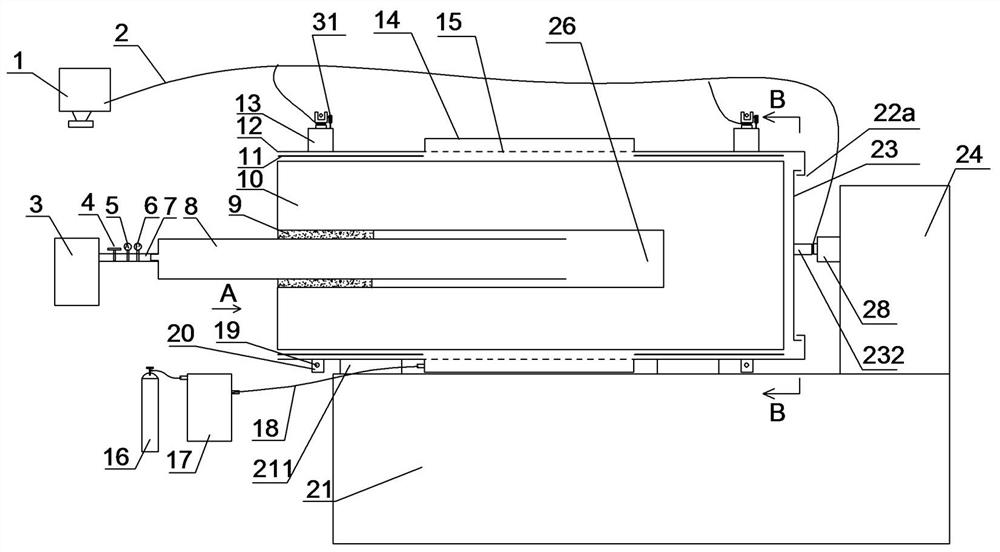

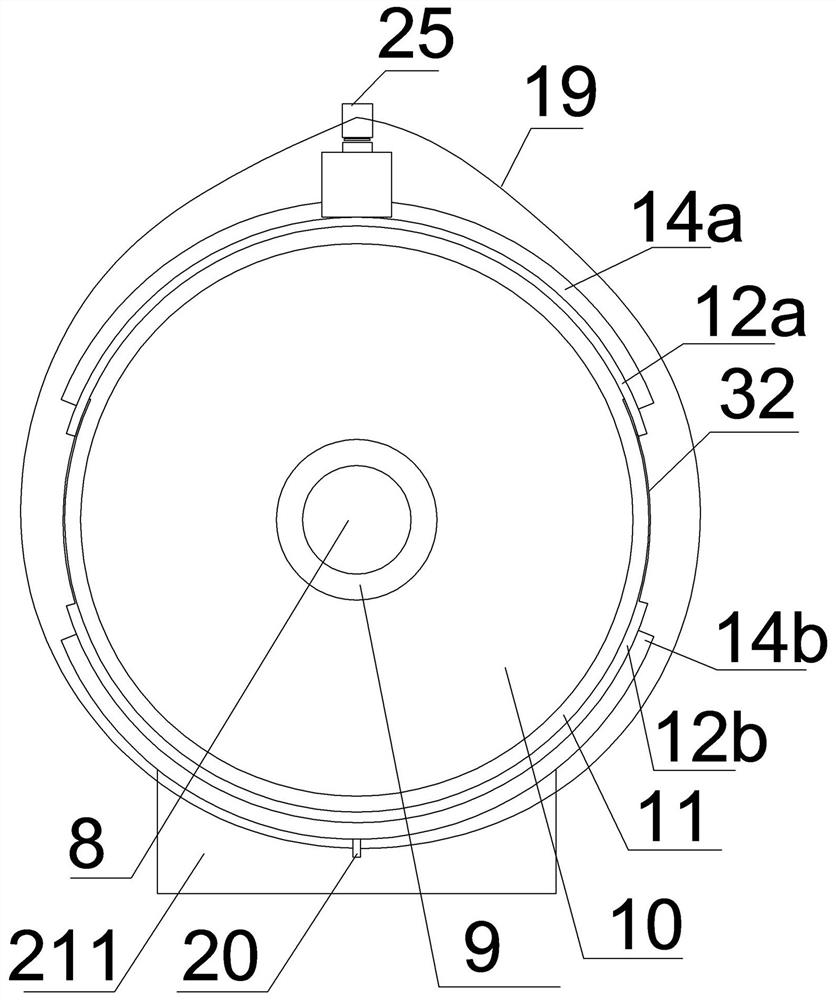

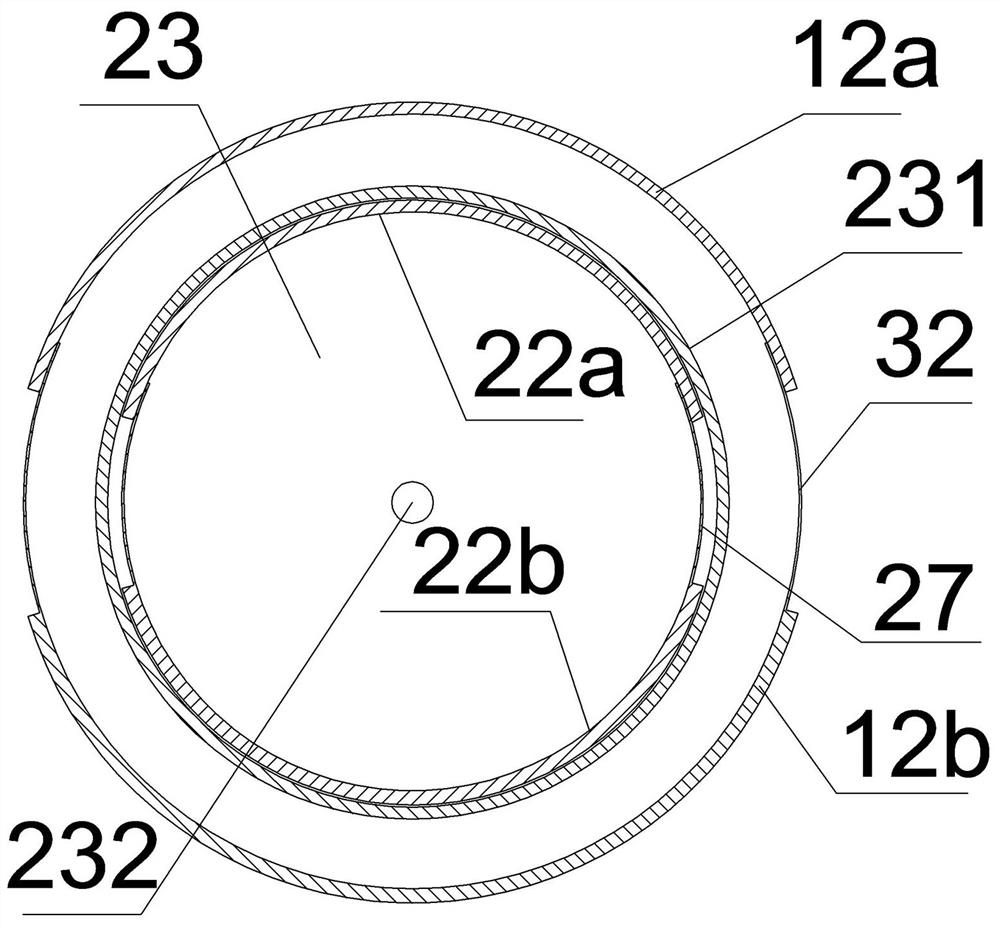

[0036] The specific embodiment of the present invention sees Figure 1-5 :

[0037] A refined simulation device for gas variable negative pressure drainage system, such as Figure 1-5 , comprising a base 21, a sample cylinder 12 placed on the base 21 and a coal body 10 filled in the sample cylinder 12, the base 21 is provided with a support seat 211, and the top of the support seat 211 is a groove adapted to the shape of the sample cylinder 12, The gap between the coal body 10 and the sample cylinder 12 is provided with a rubber body 11, and also includes a negative pressure pump 3, a gas cylinder 16, a pressure pump 17 and a gas injection pipe 18. One end of the sample cylinder 12 is open and drilled into the coal seam. There is a borehole 26, and a drainage pipe 8 extends into the borehole 26, and a sealing body 9 located at the entrance of the drilling hole 26 is filled between the drainage pipe 8 and the drilling hole 26, and the sealing body 9 is made of polyurethane mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com