A static stiffness test device and test method for a ship system pipeline support

A pipeline support and testing device technology, which is applied in the direction of measuring devices, elastic testing, mechanical parts testing, etc., can solve problems such as difficult installation and disassembly, lack of versatility, inaccurate test results, etc., to achieve convenient replacement and The effect of disassembly, large loading range and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will now be described in conjunction with the accompanying drawings, and the present invention is not limited to the following embodiments.

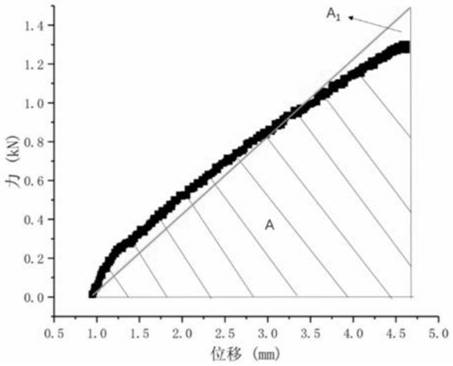

[0027] Such as Figure 1-Figure 2 As shown, a device for testing the static stiffness of a ship system pipeline support includes a main body frame, a loading device and a pipeline support clamping device. The lower fixing seats are connected by four guide posts 7 located at the four corners, and a through hole is opened in the center of the upper fixing frame so that the oil cylinder can pass through up and down; Connected, the bottom is provided with connecting lugs 11 and the hinged support provided on the top of the sliding platform is hingedly connected through the rotating shaft, the pressure head is connected with the bottom of the sliding platform, and the four corners of the sliding platform are respectively connected with four guide columns. Sliding, by fixing the pressure head on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com