Pre-laying self-adhesion polymer modified bituminous waterproof sheet material and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of textiles and paper making, which can solve the problems of poor peel strength, poor water channeling resistance, poor static load capacity, etc., and achieve good self-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

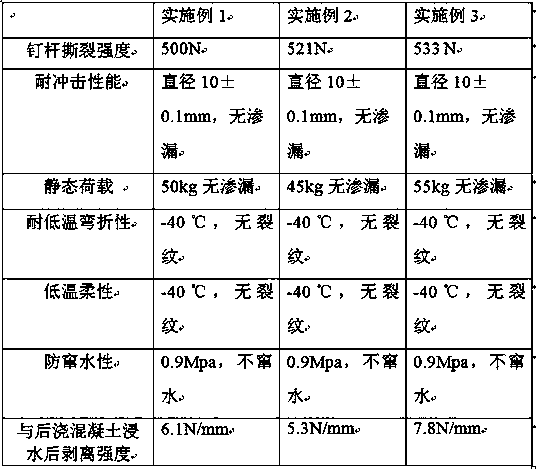

[0034] Example 1 A pre-paved self-adhesive polymer modified asphalt waterproof membrane

[0035] The pre-paved self-adhesive polymer modified asphalt waterproofing membrane includes an isolation layer, a polyester tire base cloth, a modified asphalt layer, an anti-seepage layer, and a bottom isolation membrane;

[0036] The isolation layer is: fine sand with a thickness of 0.5 mm and a fineness of 100 mesh;

[0037] The polyester base fabric: 195g / ㎡ filament polyester base fabric, tensile strength > 500N / 5cm, thickness 1.15mm, moisture content ≤ 1.5%.

[0038] The modified asphalt layer includes the following raw material components in parts by weight:

[0039] 75 parts of No. 130 bitumen, 55 parts of No. 90 bitumen, 8 parts of wood wax oil, 8 parts of propyl paraben, 14 parts of coumarone resin, 9 parts of SBR, 5 parts of EVA, 9 parts of coal tar, xanthan gum 7 parts, 12 parts of dicyclopentadiene-based petroleum resin, 17 parts of terpene phenolic resin, 2.5 parts of sorbi...

Embodiment 2

[0044] Example 2 A pre-paved self-adhesive polymer modified bitumen waterproof membrane

[0045] The pre-paved self-adhesive polymer modified asphalt waterproofing membrane includes an isolation layer, a polyester tire base cloth, a modified asphalt layer, an anti-seepage layer, and a bottom isolation membrane;

[0046] The isolation layer is: fine sand with a thickness of 0.8 mm and a fineness of 200 mesh;

[0047] The polyester base fabric: 195g / ㎡ filament polyester base fabric, tensile strength > 500N / 5cm, thickness 1.15mm, moisture content ≤ 1.5%.

[0048] The modified asphalt layer includes the following raw material components in parts by weight:

[0049] 80 parts of No. 130 bitumen, 50 parts of No. 90 bitumen, 9 parts of wood wax oil, 7 parts of propyl paraben, 11 parts of coumarone resin, 12 parts of SBR, 5.8 parts of EVA, 7 parts of coal tar, xanthan gum 8 parts, 15 parts of dicyclopentadiene-based petroleum resin, 15 parts of terpene phenolic resin, 2 parts of sorb...

Embodiment 3

[0054] Example 3 A pre-paved self-adhesive polymer modified bitumen waterproof membrane

[0055] The pre-paved self-adhesive polymer modified asphalt waterproofing membrane includes an isolation layer, a polyester tire base cloth, a modified asphalt layer, an anti-seepage layer, and a bottom isolation membrane;

[0056] The isolation layer is: fine sand with a thickness of 0.5 mm and a fineness of 100 mesh;

[0057] The polyester base fabric: 195g / ㎡ filament polyester base fabric, tensile strength > 500N / 5cm, thickness 1.15mm, moisture content ≤ 1.5%.

[0058] The modified asphalt layer includes the following raw material components in parts by weight:

[0059] 78 parts of No. 130 bitumen, 53 parts of No. 90 bitumen, 8.4 parts of wood wax oil, 7.5 parts of propyl paraben, 13 parts of coumarone resin, 10 parts of SBR, 5.5 parts of EVA, 8 parts of coal tar, xanthan gum 7.2 parts, 13 parts of dicyclopentadiene petroleum resin, 16 parts of terpene phenolic resin, 2.3 parts of so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com