A kind of car paint surface cleaning and repairing agent and preparation method thereof

A technology of repairing agent and car paint, which is applied in the field of paint repair, can solve the problems of difficult balance between cleaning and repairing functions, very high requirements for operation skills, and difficulty for ordinary consumers to master, so as to save repairing costs and construction costs, and is convenient Spraying, the effect of ensuring the uniformity of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

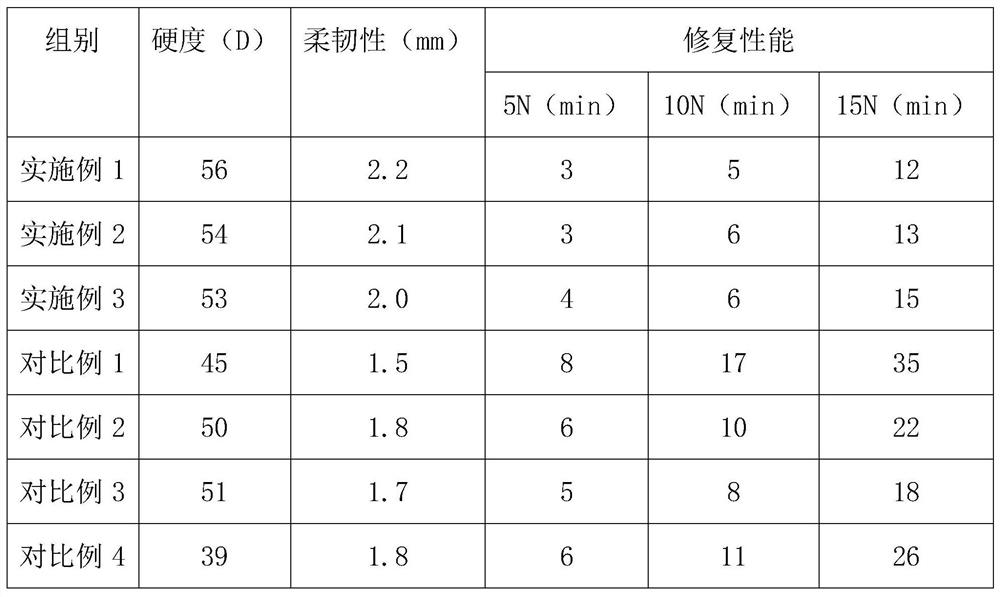

Examples

Embodiment 1

[0038] A cleaning and repairing agent for automobile paint surface of the present embodiment is composed of the following components by weight: 6 parts of fatty alcohol polyoxyethylene ether, 10 parts of oleic acid diethanolamide borate, 1.8 parts of sodium alginate, 10 parts of xylene parts, 4 parts of dimethylformamide, 2 parts of dimethyl silicone oil, 2.7 parts of self-healing filler, 55 parts of diluent; wherein, the diluent consists of acetone, ethyl acetate, toluene, cyclopentanone according to the mass ratio of 3:2 :1:1 mixed and stirred.

[0039] The preparation method of the self-healing filler is as follows:

[0040] 1) In parts by weight, add 52 parts of mesoporous silica to 290 parts of deionized water, centrifuge for 4 minutes to obtain a dispersion of mesoporous silica, raise the temperature to 115°C, add 70 parts of hydroxyethyl chitosan, and Stir at -0.16MPa for 25 minutes to obtain a mixed solution; wherein, the particle size of mesoporous silica is 250-280n...

Embodiment 2

[0049] A cleaning and repairing agent for automobile paint surface of the present embodiment is composed of the following components by weight: 5 parts of fatty alcohol polyoxyethylene ether, 8 parts of oleic acid diethanolamide borate, 2.3 parts of sodium alginate, 12 parts of xylene parts, 5 parts of dimethylformamide, 3 parts of dimethyl silicone oil, 3 parts of self-healing filler, and 58 parts of diluent. Wherein, the diluent is formed by mixing and stirring acetone, ethyl acetate, toluene, and cyclopentanone according to a mass ratio of 3:2:1:1.

[0050] The preparation method of the self-healing filler is as follows:

[0051] 1) In parts by weight, add 53 parts of mesoporous silica to 300 parts of deionized water, centrifuge for 4.2 minutes to obtain a dispersion of mesoporous silica, raise the temperature to 120°C, add 72 parts of hydroxyethyl chitosan, and Stir for 30 minutes under vacuum degree -0.18MPa to obtain a mixed solution; among them, the particle size of me...

Embodiment 3

[0060] A cleaning and repairing agent for automobile paint surface of the present embodiment is composed of the following components by weight: 7 parts of fatty alcohol polyoxyethylene ether, 11 parts of oleic acid diethanolamide borate, 3 parts of sodium alginate, 12 parts of xylene parts, 6 parts of dimethylformamide, 4 parts of simethicone, 3.1 parts of self-healing filler, and 60 parts of diluent. Wherein, the diluent is formed by mixing and stirring acetone, ethyl acetate, toluene, and cyclopentanone according to a mass ratio of 3:2:1:1.

[0061] The preparation method of the self-healing filler is as follows:

[0062] 1) In parts by weight, add 58 parts of mesoporous silica to 305 parts of deionized water, centrifuge for 5 minutes to obtain a dispersion of mesoporous silica, heat up to 120°C, add 72 parts of hydroxyethyl chitosan, and Stir for 30min at -0.2MPa to obtain a mixed solution; wherein, the particle size of mesoporous silica is 250-280nm, and the specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com