POSS enhanced high-mehcanical-property silicone rubber and preparing method thereof

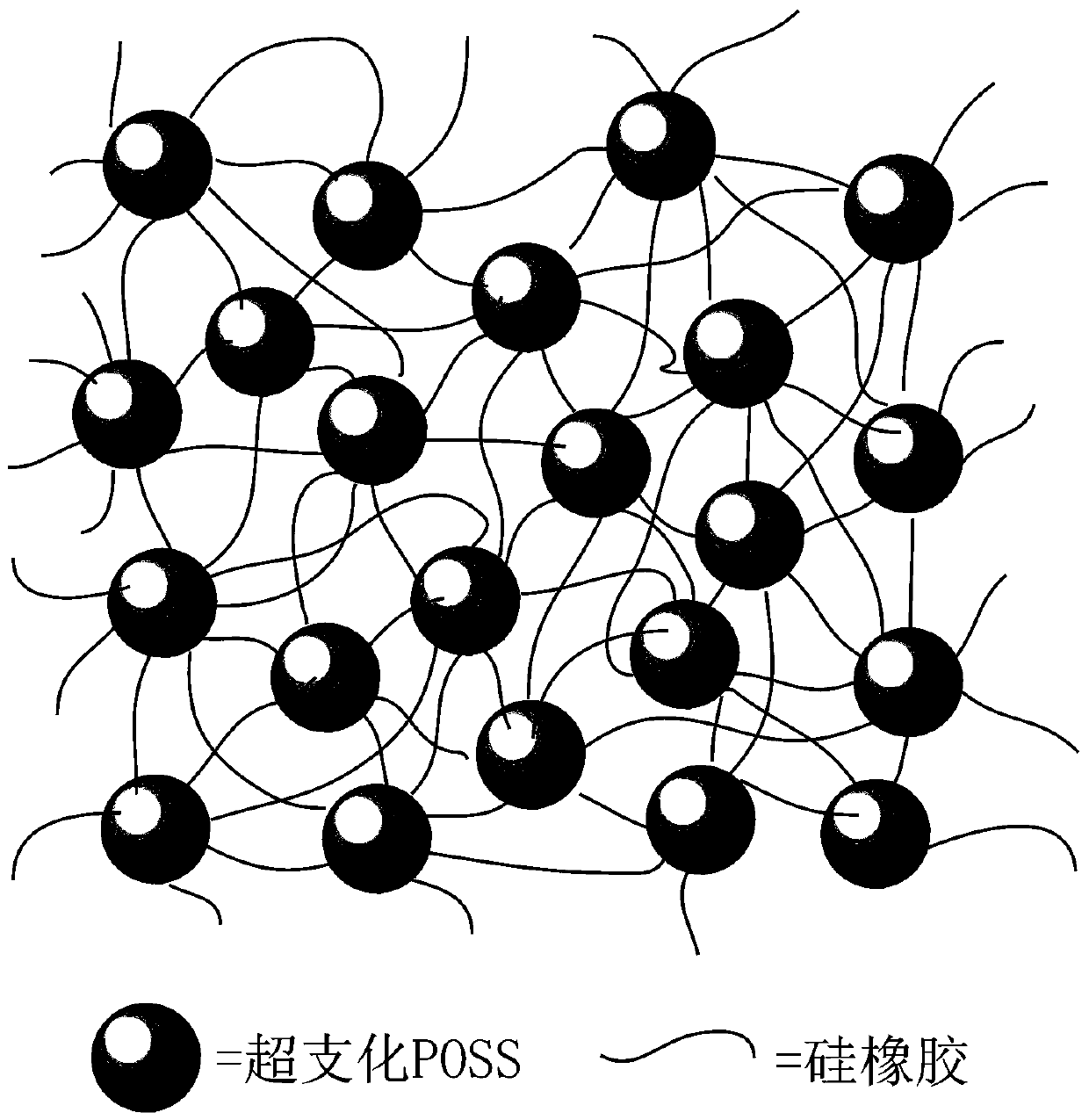

A technology for mechanical properties and silicone rubber, applied in the field of high mechanical properties silicone rubber and its preparation, can solve problems such as insufficient mechanical properties, and achieve the effects of good biocompatibility, increased application range and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

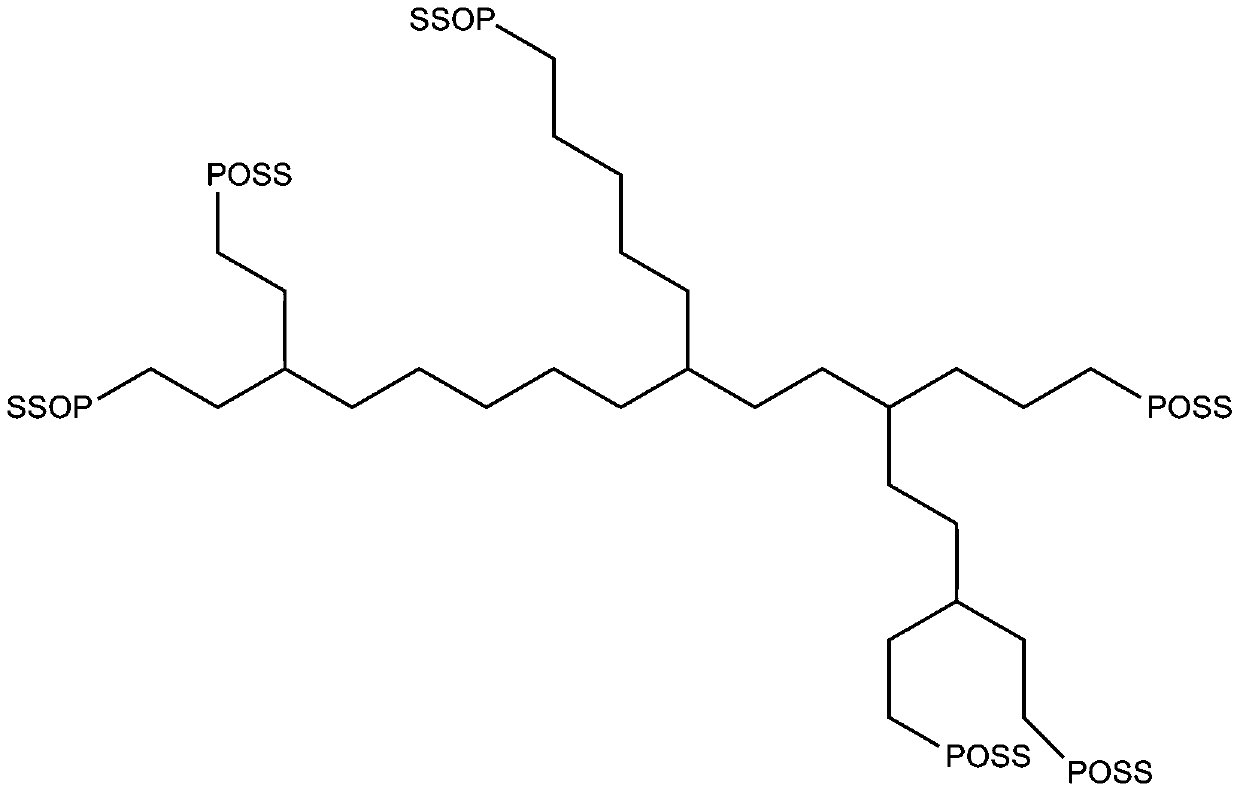

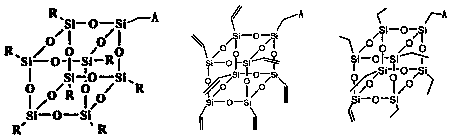

[0033] Example 1: 5g of hyperbranched POSS (the hyperbranched polymer is polyamide-amine dendritic polymer (PAMAM), the branch chain is 18, the molecular weight is 500000, and the molecular formula is AB 18 , B in the molecular formula is a polyhedral cage-type oligomeric silsesquioxane containing 4 vinyl functional groups, and the link between POSS and hyperbranched polymer is an amide bond), 5g of fumed silica and 100g of 70A hardness Methyl vinyl phenyl silicone rubber is mixed evenly in the internal mixer, and then take the silicone rubber after internal mixing and add 4g of hydrogen-containing silicone oil with an active hydrogen content of 1.5% and 3.5 g of chloroplatinic acid / olefin complex. After all the components are mixed evenly, thin pass three times, and finally the mixed rubber is vulcanized on a flat rubber vulcanizing machine at 170°C for 10 minutes to obtain medical silicone rubber with high mechanical properties.

Embodiment 2

[0034] Example 2: The steps are the same as in Example 1, but the difference is that the hyperbranched POSS: the hyperbranched polymer is a polyamide dendritic polymer (polyamide), with 120 branches, a molecular weight of 1,000,000, and a molecular formula of AB 120、 B in the molecular formula is polyhedral cage oligomeric silsesquioxane containing one vinyl functional group, the link between POSS and hyperbranched polymer is an ester bond, and the mass of hyperbranched POSS is 10g.

Embodiment 3

[0035] Example 3: The steps are the same as in Example 1, but the difference is that the hyperbranched POSS: the hyperbranched polymer is a polylysine dendritic polymer (PLL), with 4 branches and a molecular weight of 5000. Molecular formula is AB 4、 B in the molecular formula is a polyhedral cage-type oligomeric silsesquioxane containing 8 vinyl functional groups, the link between POSS and the hyperbranched polymer is a urethane bond, and the mass of the hyperbranched POSS is 0.01 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com