Self-healing hydrogel and preparation method thereof

A hydrogel and self-healing technology, applied in the field of self-healing hydrogel and its preparation, can solve problems such as lack of self-healing properties, achieve good self-healing effect, simple healing conditions, and super mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

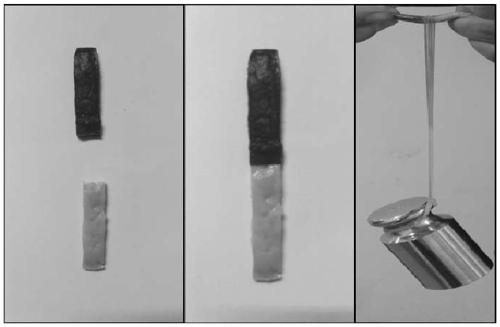

[0019] Firstly, 3 g of isopropylacrylamide, 10 mL of water, and 20 mL of nano-silica sol were uniformly mixed, stirred for 10 min, and ultrasonicated for 30 min to uniformly disperse the nano-silica particles in the solution. Add 80 mg of ammonium persulfate and 150 μL of N,N,N,N-tetramethylethylenediamine, and stir until the solution is uniform and stable. Stand in an oven at 60°C for 30 minutes, then soak in 1mol / L sodium hydroxide solution, and stir gently to fully soak and strengthen the material. Compress the cross-linked gel in a mold. After drying at room temperature for 15 days, a self-healing hydrogel with super-strong mechanical properties was obtained. Such as figure 1 As shown, the self-healing hydrogel was subjected to a shear test using a universal compression testing machine, and the section was soaked in 75% ethanol solution, and after splicing together, it was dried at room temperature for 15 days. A universal testing machine was used to test the shear stre...

Embodiment 2

[0021] Firstly, 3g of isopropylacrylamide, 10mL of water, and 15mL of nano-silica sol were uniformly mixed, stirred for 10 minutes, and ultrasonicated for 30 minutes to evenly disperse the nano-silica particles in the solution. Add 60 mg of ammonium persulfate and 150 μL of N,N,N,N-tetramethylethylenediamine, and stir until the solution is uniform and stable. Stand in an oven at 60°C for 30 minutes. Take out the sample, soak it in 1mol / L sodium hydroxide solution to obtain the colloid, then extrude the colloid into a mold, and dry it at room temperature for 10-15 days to obtain a self-healing hydrogel with super strong mechanical properties. Such as figure 1 As shown, the above self-healing hydrogel was subjected to a shear test using a universal compression testing machine, and the section was soaked in 75% ethanol solution, and after being spliced together, it was dried at room temperature for 15 days. A universal testing machine was used to test the shear stress of the ...

Embodiment 3

[0023] Firstly, 3g of isopropylacrylamide, 15mL of water, and 15mL of nano-silica sol were uniformly mixed, stirred for 10 minutes, and ultrasonicated for 30 minutes to uniformly disperse the nano-silica particles in the solution. Add 60 mg of ammonium persulfate and 150 μL of N,N,N,N-tetramethylethylenediamine, and stir until the solution is uniform and stable. Stand in an oven at 60°C for 30 minutes. Take out the sample, soak it in 1mol / L sodium hydroxide solution to obtain the colloid, then extrude the colloid into a mold, and dry it at room temperature for 10-15 days to obtain a self-healing hydrogel with super strong mechanical properties. Such as figure 1 As shown, the above self-healing hydrogel was subjected to a shear test using a universal compression testing machine. The cross-section was soaked in an aqueous solution, and after being spliced together, it was dried at room temperature for 15 days. A universal testing machine was used to test the shear stress of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com