Grain-oriented electrical steel sheet and manufacturing method thereof

A technology of grain-oriented electrical steel sheet and manufacturing method, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of coil annealing, coil temperature deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

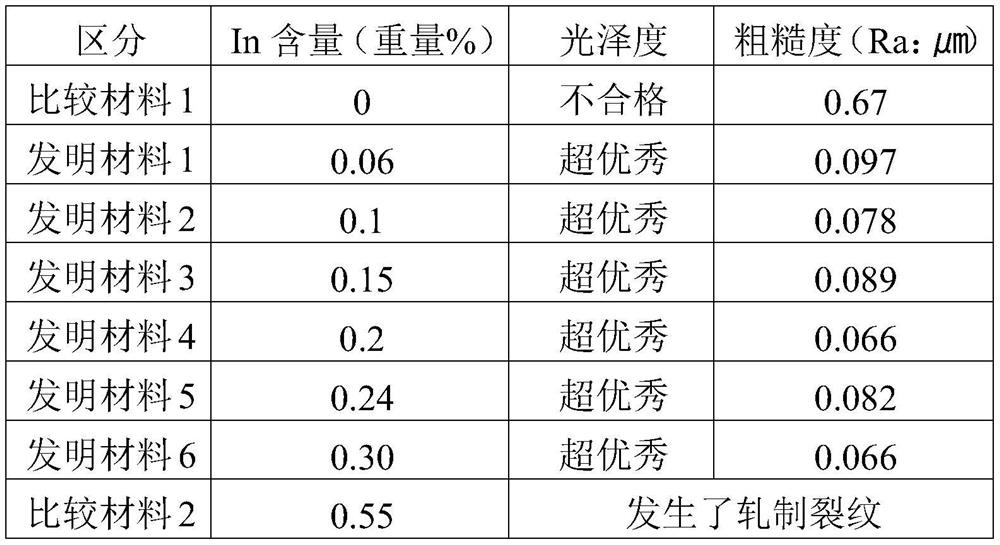

[0087] Steel slabs containing 3.2% by weight of Si, 0.052% of C, additionally added In as organized in Table 1 below, and the remainder including Fe and other unavoidable impurities were produced. The steel billet was hot-rolled to produce a 2.6 mm hot-rolled sheet, and then the hot-rolled sheet was annealed and pickled, and then cold-rolled to a final thickness of 0.3 mm.

[0088] After raising the temperature of the cold-rolled sheet, keep the temperature at 850°C for 120 seconds in a mixed gas atmosphere with a dew point temperature of 63 to 67°C formed by adding 50% by volume of hydrogen and 50% by volume of nitrogen at the same time, and implement decarburization and nitriding at the same time. Treated so that carbon becomes 30 ppm or less and nitrogen becomes 300 ppm.

[0089] On this steel sheet, MgO was coated as an annealing separator, and secondary recrystallization annealing was performed. MgO was applied in a slurry state mixed with water, and no other additives w...

Embodiment 2

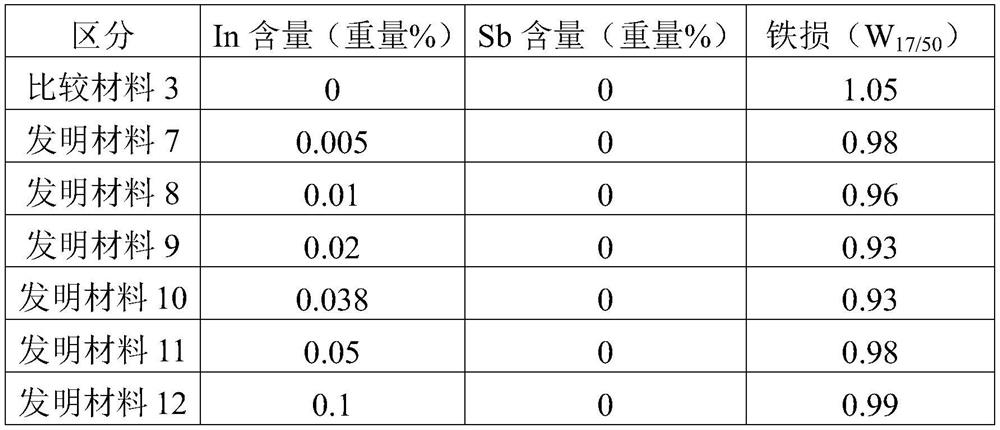

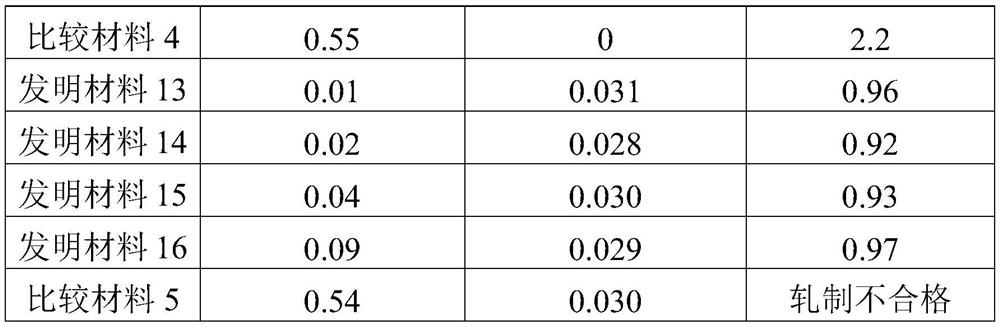

[0095] A slab of grain-oriented electrical steel sheet was prepared, which contained 3.0% of Si, 0.051% of C, 0.09% of Mn, 0.029% of Al, 0.0040% of N and 0.005% of S in % by weight, as shown in Table 2. Indium (In) and Sb changed as described above, the remaining components including Fe and other impurities that are inevitably mixed. The slab was heated at 1150°C for 90 minutes, then hot-rolled, then rapidly cooled to 580°C, annealed at 580°C for 1 hour for furnace cooling, and hot-rolled to produce a 2.3mm-thick hot-rolled sheet.

[0096] After heating this hot-rolled sheet at a temperature of 1,050° C. or higher, it was kept at 910° C. for 80 seconds, rapidly cooled with boiling water, and then pickled. Next, cold rolling was performed to obtain a thickness of 0.30 mm. After raising the temperature of the cold-rolled sheet, keep the temperature at 850°C for 120 seconds in a mixed gas atmosphere with a dew point temperature of 63 to 67°C formed by adding 50% by volume of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com