Flexible electrode film and preparation method and application thereof

A flexible electrode and film technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as poor cycle stability, low capacity utilization efficiency of positive electrode materials, and low electronic conductivity, so as to reduce reaction polarization, Inhibit the shuttle effect and improve the effect of liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

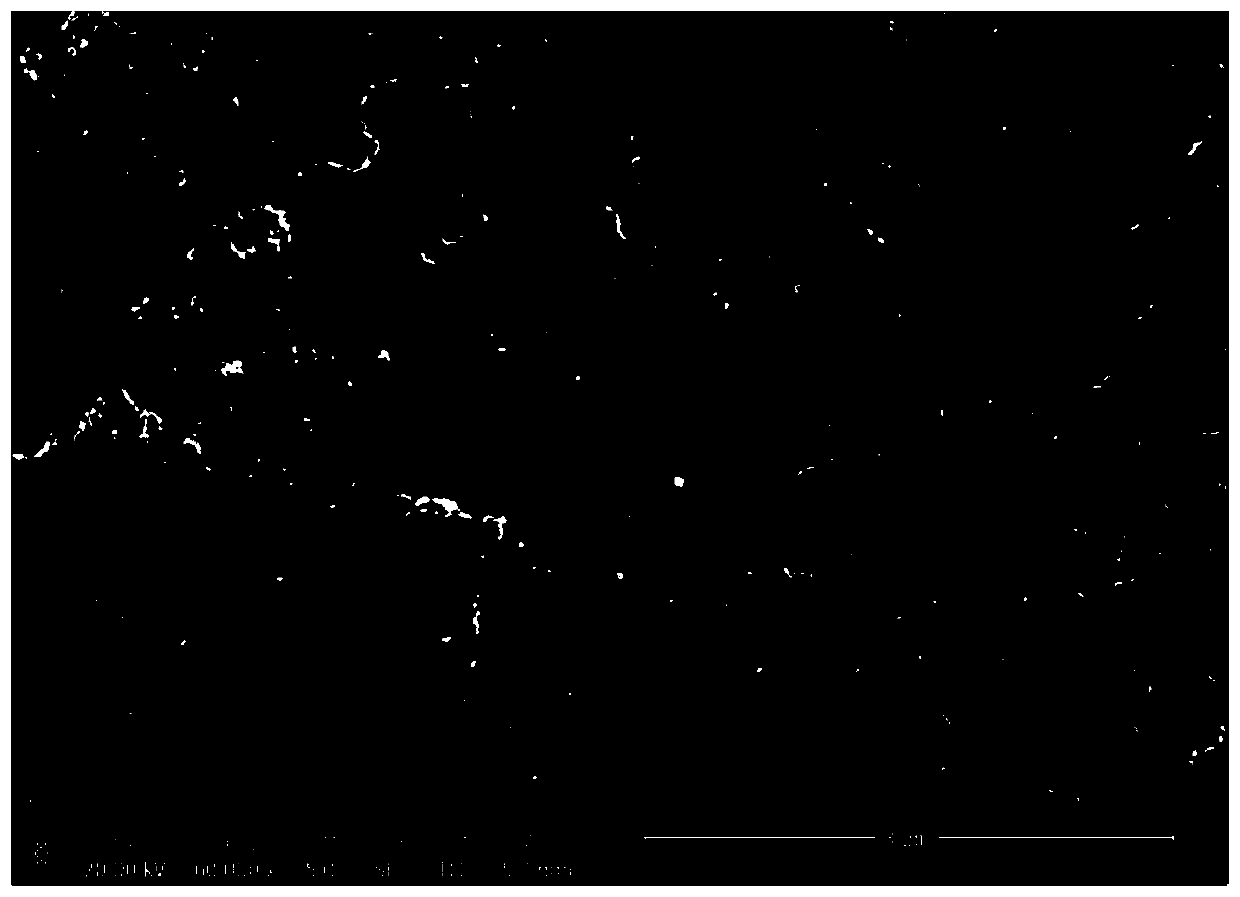

Image

Examples

Embodiment 1

[0059] Step 1: The specific surface area of elemental sulfur and BET is 400m 2 / g of fluorinated carbon black is mechanically mixed according to a mass ratio of 1:0.3, then added to a ball mill, and dry ball milled for 0.5h, then the above materials are kept in an argon atmosphere at a temperature of 155°C for 24h, and the argon environment is cooled to room temperature. Then, the above materials are ground and refined, and passed through a 300-mesh sieve to obtain a carbon fluoride-loaded sulfur composite material;

[0060] Step 2: Grind and mix the carbon fluoride-supported sulfur composite material and carbon nanotubes with a diameter of less than 5nm at a mass ratio of 8:1 for more than 30 minutes, and then use the carbon fluoride-supported sulfur composite material: carbon nanotubes: polytetrafluoroethylene The mass ratio of the mixture is 8:1:1, adding 15% by mass of polytetrafluoroethylene emulsion, grinding and stirring into a snow flake mixture;

[0061] Step 3: Ad...

Embodiment 2

[0066] Step 1: Make the specific surface area of elemental sulfur and BET 300m 2 / g of porous fluorinated graphene is mechanically mixed according to the mass ratio of 1:0.2, then added to the ball mill, dry ball milled for 1.0h, and then the above materials are kept in an argon atmosphere at a temperature of 155°C for 12h, and the argon environment is cooled to room temperature , and then grind and refine the above-mentioned materials and pass through a 300-mesh sieve to obtain a carbon fluoride-loaded sulfur composite material;

[0067] Step 2: Grind and mix the carbon fluoride-supported sulfur composite material and carbon nanotubes with a diameter of less than 5nm at a mass ratio of 8:1 for more than 30 minutes, and then use the carbon fluoride-supported sulfur composite material: carbon nanotubes: polytetrafluoroethylene The mass ratio of the mixture is 8:1:1, adding 15% by mass of polytetrafluoroethylene emulsion, grinding and stirring into a snow flake mixture;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com