Conductive silver paste for touch screen using transfer process and preparation method thereof

A technology of conductive silver paste and touch screen, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of high manufacturing costs, flat screen printing technology cannot meet three-dimensional printing technology, etc., and achieve The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of conductive silver paste for a transfer printing process touch screen, the method comprising the following steps:

[0024] (1) Preparation of organic carrier: Prepare 100Kg of carrier, weigh 30kg of polyurethane resin, 35kg of ester solvent and 35kg of ketone solvent, stir to wet the resin, then heat it up to 80°C and keep the temperature constant until the resin is completely dissolved. When it is cooled to below 40°C, it is filtered on a 300-400-mesh mesh cloth to obtain an organic carrier.

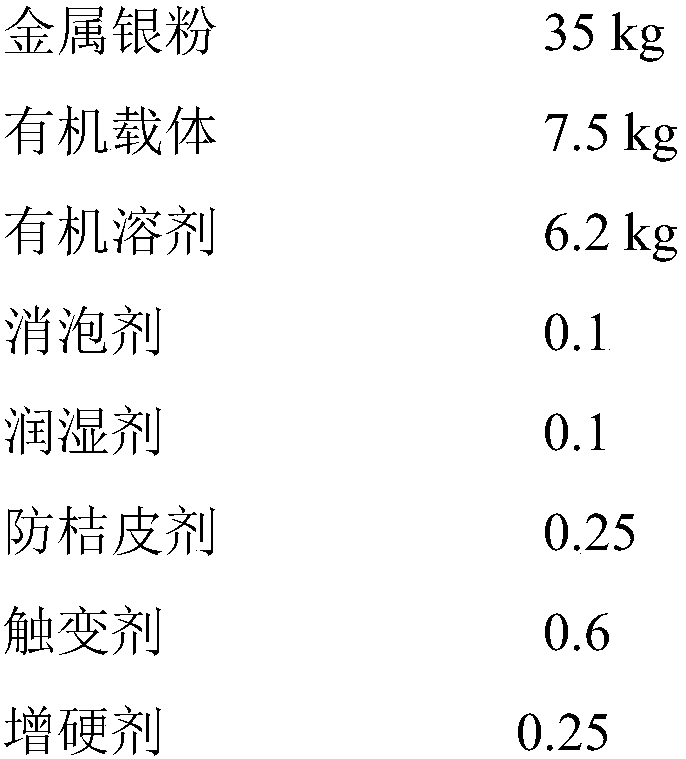

[0025] (2) Prepare materials, prepare materials according to the following components and contents:

[0026]

[0027] In the metal silver powder used, the particle size is 1.2 μm, and the tap density is 4.8 g / ml;

[0028] (3) Preparation of silver paste: Weigh metal silver powder, mix it with organic carrier, defoamer, wetting agent, anti-orange peel agent, thixotropic agent, hardening agent in a mixer, and then use The high-speed disperser performs hi...

Embodiment 2

[0032] A preparation method of conductive silver paste for a transfer printing process touch screen, the method comprising the following steps:

[0033] (1) Preparation of organic carrier: Prepare 100Kg of carrier, weigh 30kg of polyurethane resin and 70kg of ester solvent, stir to wet the resin, then heat it up to 80°C and keep the temperature constant until the resin is completely dissolved, then cool to below 40°C Filter it on a mesh cloth of 300-400 mesh to remove impurities to obtain an organic carrier.

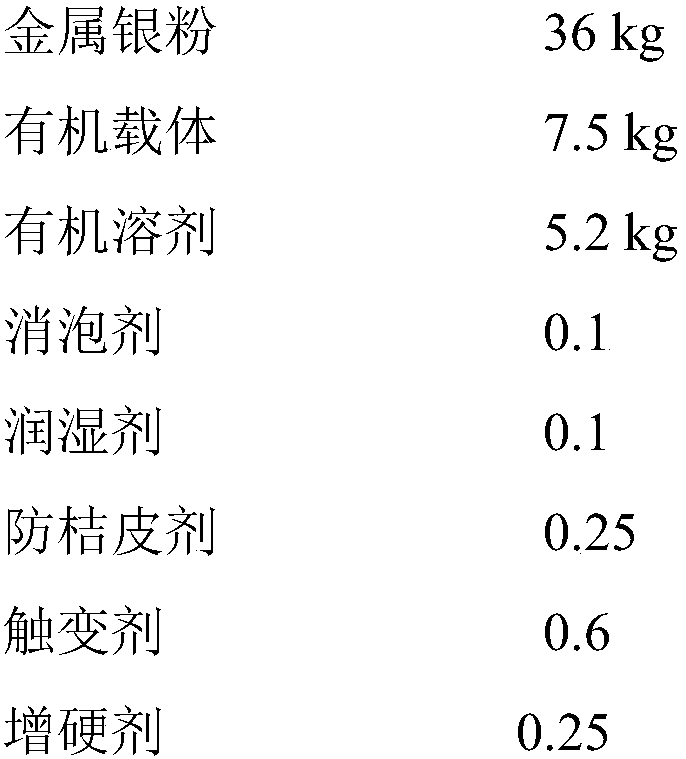

[0034] (2) Prepare materials, prepare materials according to the following components and contents:

[0035]

[0036] The metal silver powder used had an average particle diameter of 1.5 μm and a tap density of 4.8 g / ml. ;

[0037] (3) Preparation of silver paste: Weigh metal silver powder, mix it with organic carrier, defoamer, wetting agent, anti-orange peel agent, thixotropic agent, hardening agent in a mixer, and then use The high-speed disperser performs high-...

Embodiment 3

[0041] A preparation method of conductive silver paste for a transfer printing process touch screen, the method comprising the following steps:

[0042] (1) Preparation of organic carrier: Prepare 100Kg of carrier, weigh 30kg of saturated polyester resin, 30kg of ester solvent and 40kg of ketone solvent, stir to wet the resin, then heat it up to 80°C and keep the temperature constant until the resin is completely Dissolve it, and when it is cooled to below 40°C, filter it on a 300-400-mesh mesh cloth to obtain an organic vehicle.

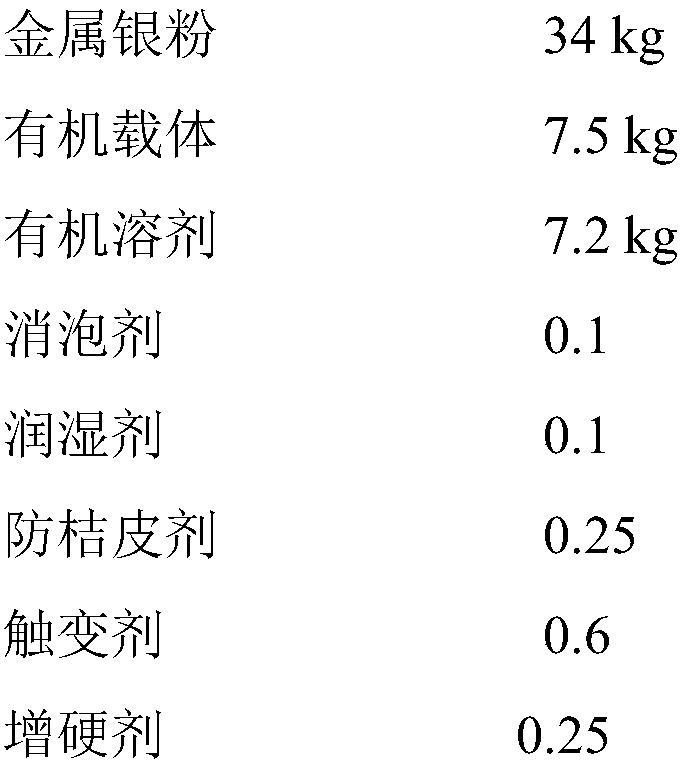

[0043] (2) Prepare materials, prepare materials according to the following components and contents:

[0044]

[0045] The metal silver powder used has a particle size of 2 μm and a tap density of 4.0 g / ml;

[0046] (3) Preparation of silver paste: Weigh metal silver powder, mix it with organic carrier, defoamer, wetting agent, anti-orange peel agent, thixotropic agent, hardening agent in a mixer, and then use The high-speed disperser performs h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com