Preparation method of carboxyl and polypeptide modified AIE polymer nanoparticles

A nanoparticle, polypeptide modification technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as limiting the application value in the field of selective cell imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Weigh 0.2g of O-50 emulsifier and dissolve in 12.5g of deionized water to obtain an aqueous solution.

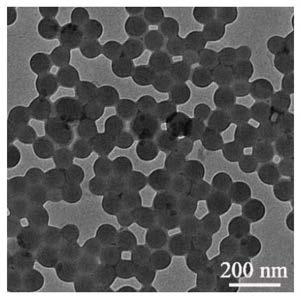

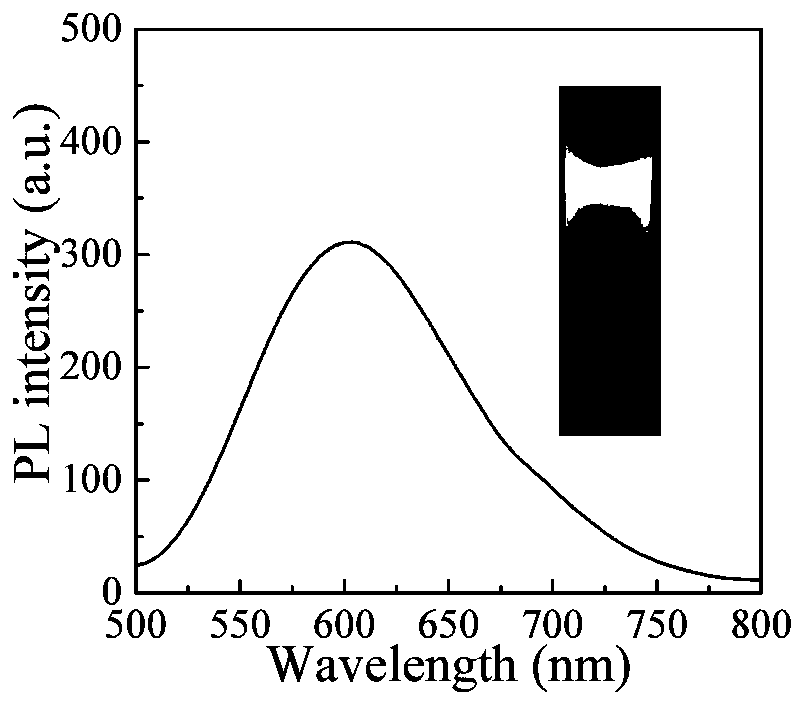

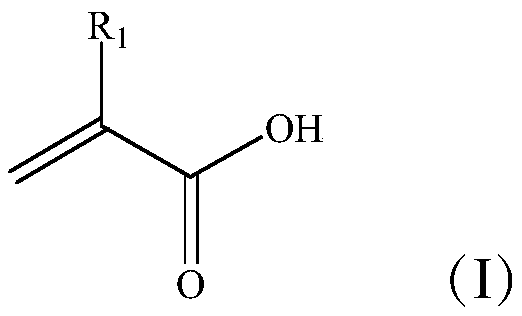

[0072] Weigh 0.01g of AIE-6 molecules and dissolve them in a mixed solution of 0.06g n-hexadecane, 0.1g acrylic acid, 0.45g styrene and 0.45g methyl methacrylate to obtain an oil phase solution; add the water phase solution to In the oil phase solution, a coarse emulsion is prepared after stirring and pre-emulsification; the container containing the coarse emulsion is placed in an ice water bath, and ultrasonic waves with a power of 400W are used for 9min to obtain a stable monomer fine emulsion; nitrogen removal , Adding 0.02g potassium persulfate, raising the temperature to 70°C, and reacting for 6h under the protection of nitrogen to obtain a carboxyl modified AIE polymer nanoparticle emulsion. With molecular weight cutoff 5000g·mol -1 The dialysis bag was dialyzed for three days, and the water change frequency was every 2h on the first day, every 3h on the second da...

Embodiment 2

[0086] Weigh 0.5 g of Tween 20 and dissolve in 15 g of deionized water to obtain an aqueous solution.

[0087] Weigh 0.0075g of AIE-12 molecule and dissolve it in a mixed solution of 0.08g n-hexadecane, 0.15g methacrylic acid and 1.35g methyl methacrylate to obtain an oil phase solution; add the water phase solution to the oil phase solution After stirring and pre-emulsification, the coarse emulsion is prepared; the container containing the coarse emulsion is placed in an ice water bath, and ultrasonic waves with a power of 200 W are used for 20 minutes to obtain a stable monomer fine emulsion; 0.015g of ammonium persulfate, the temperature was raised to 70°C, and the reaction was carried out for 10 hours under the protection of nitrogen to prepare the carboxyl modified AIE polymer nanoparticle emulsion. With a molecular weight cutoff of 5000g·mol -1 The dialysis bag was dialyzed for three days, and the water change frequency was every 2h on the first day, every 3h on the second...

Embodiment 3

[0093] Weigh 0.3 g of MOA-9 and dissolve in 15 g of deionized water to obtain an aqueous phase solution.

[0094] Weigh 0.003g of AIE-15 molecule and dissolve it in a mixed solution of 0.08g n-hexadecane, 0.05g methacrylic acid, 0.45g methyl methacrylate and 0.5g styrene to obtain an oil phase solution; Add it to the oil phase solution, stir and pre-emulsify to obtain a coarse emulsion; place the container with the coarse emulsion in an ice water bath, and sonicate it with an ultrasonic wave with a power of 600W for 5 minutes to obtain a stable monomer fine emulsion; Deoxygenation, adding 0.05g potassium persulfate, raising the temperature to 72°C, and reacting for 6h under the protection of nitrogen to prepare a carboxyl modified AIE polymer nanoparticle emulsion. With molecular weight cutoff 5000g·mol -1 The dialysis bag was dialyzed for three days, and the water was changed every 2h on the first day, every 3h on the second day, and every 6h on the third day to prepare purifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com