Panel waste recycling system and recycling method

A waste recycling and board technology, applied in the direction of grain processing, etc., can solve the problems of poor quality, a large amount of waste fiber cement board, substandard products, etc., and achieve the effect of increasing the fire resistance limit and density, high slurry quality, and fast grinding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

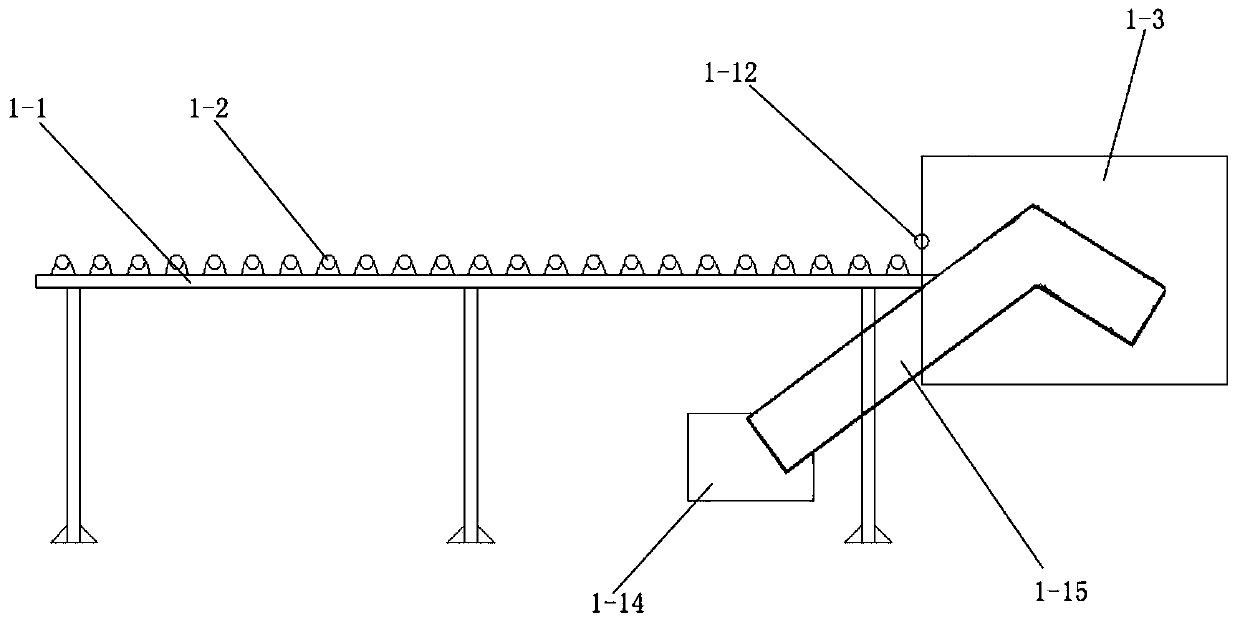

[0036] A board scrap recycling system, see Figure 1-4 , including a frame 1-1, a crusher 1 arranged on the frame for crushing waste materials, a feeder 2 for transporting crushed waste materials, and a conveying belt 3, the end of the conveying belt 3 is connected to the ball mill 4, and the outlet of the ball mill 4 The feed port is connected with a stirring tank 5;

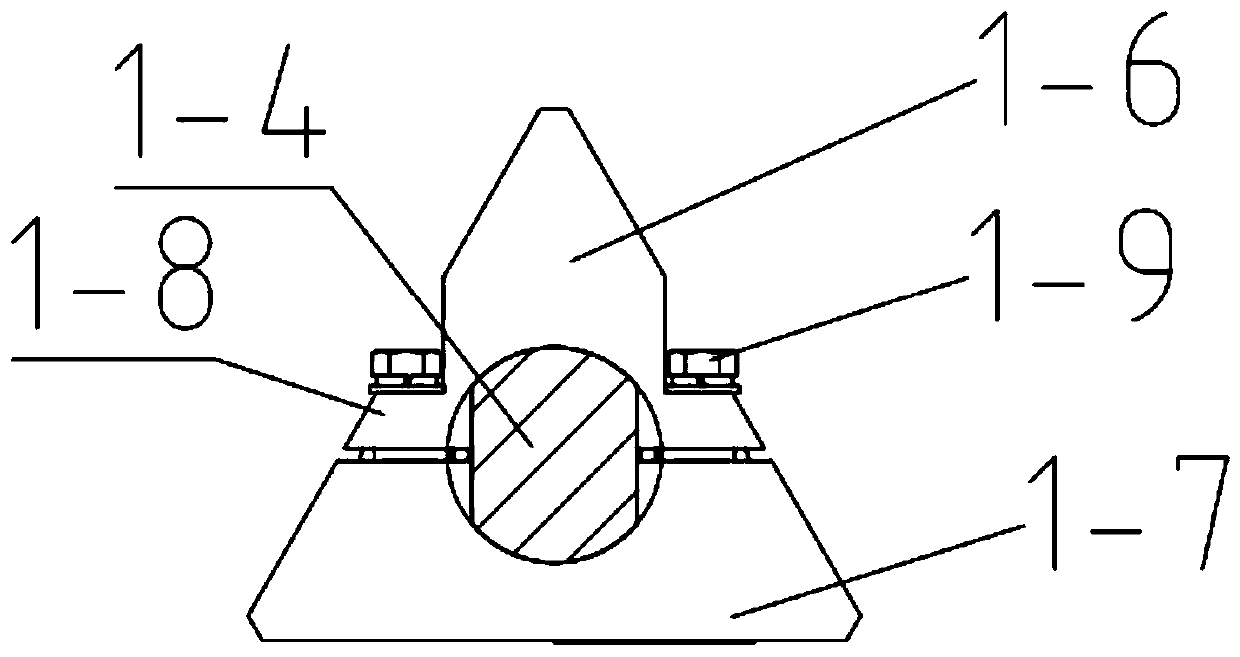

[0037] The crusher 1 includes conveying rollers 1-2 for conveying waste and a crushing box 1-3 for crushing waste. The crushing box 1-3 is provided with a crushing shaft 1-4, and the crushing shaft 1-4 is provided with a plurality of triangular crushing knife 1-5;

[0038] The section of the triangular crushing knife 1-5 is a triangular structure, and the crushing shaft 1-4 passes through the center of the triangle.

[0039] The crusher in the plate waste recycling system of the present invention can effectively crush the waste, and then transport the crushed waste to the ball mill tank. The dosage can be up...

Embodiment 2

[0047] A method for recycling board waste, realized through the above board waste recycling system, comprising:

[0048] Step 1: The discarded scraps and unqualified plates are crushed by a crusher to form irregular block plates with a length of no more than 100mm;

[0049] Step 2: Transport the preliminarily crushed waste to the tank of the ball mill through the feeder and the conveyor belt, and feed 15t; during the feeding process, the hard material (density 1400kg / m 3Above) accounted for 60 parts, soft materials accounted for 40 (density 1400kg / m 3 Below) part, 0.1 part of grinding aid colloidal silicon dioxide;

[0050] Step 3: Add balls into the ball mill first, then add water while adding waste materials, the amount of water added is subject to more than 90% of the barrel of the ball mill, and the grinding time is 10 hours;

[0051] The internal grinding door of the ball mill is lined with medium aluminum bricks, and the grinding balls are medium aluminum balls and SiO...

Embodiment 3

[0054] A method for recycling board waste, realized through the above board waste recycling system, comprising:

[0055] Step 1: The discarded scraps and unqualified plates are crushed by a crusher to form irregular block plates with a length of no more than 100mm;

[0056] Step 2: Transport the preliminarily crushed waste to the ball mill tank through the feeder and the conveyor belt, and feed 16t; during the feeding process, the hard material (density 1400kg / m 3 Above) accounted for 70 parts, soft materials accounted for 30 (density 1400kg / m 3 Below) part, 0.5 part of grinding aid colloidal graphite;

[0057] Step 3: Add balls into the ball mill first, then add water while adding waste materials, the amount of water added is subject to more than 90% of the barrel of the ball mill, and the grinding time is 12 hours;

[0058] The internal grinding door of the ball mill is lined with medium aluminum bricks, and the grinding balls are medium aluminum balls and SiO 2 The balls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com