Preparation method of montmorillonite/graphite phase carbon nitride composite photocatalysis material

A graphite phase carbon nitride, montmorillonite technology, applied in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc., can solve the problems of high raw material cost, complex synthesis process, etc., and achieve low raw material cost. , The preparation method is simple and easy, and the effect is suitable for large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Graphite phase carbon nitride photocatalyst, it is prepared by following steps:

[0026] (1) Take by weighing 10g urea and add in the crucible, add a cover and put into the muffle furnace;

[0027] (2) Raise the temperature to 550° C. at a rate of 5° C. / min, keep the temperature constant for 2 hours, and grind the product to obtain a graphite-phase carbon nitride photocatalyst.

Embodiment 2

[0029] A kind of montmorillonite / graphite phase carbon nitride composite photocatalyst, it is prepared by following steps:

[0030] (1) Add 2 mg of montmorillonite into 30 mL of ultrapure water, stir evenly and then ultrasonically for 30 minutes to obtain a montmorillonite suspension;

[0031] (2) Add 10 g of urea to the above-mentioned montmorillonite suspension, and stir overnight in a water bath at 50° C.;

[0032] (3) The mixture in step (2) is freeze-dried, and the resulting solid mixture is ground and transferred to a covered crucible for

[0033] Raise the temperature at a rate of 5°C / min to 550°C, keep the temperature constant for 2 hours, and grind the product to obtain 1.0% Mt / g-C 3 N 4 composite photocatalyst.

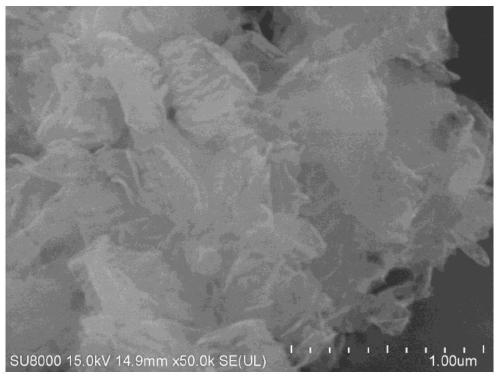

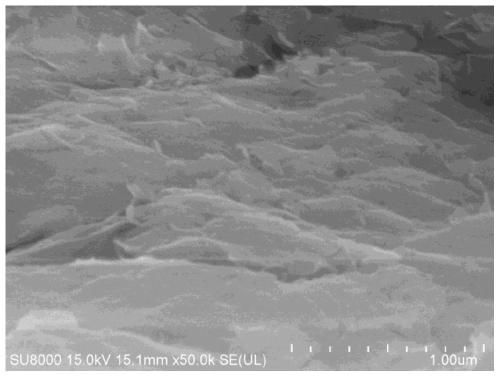

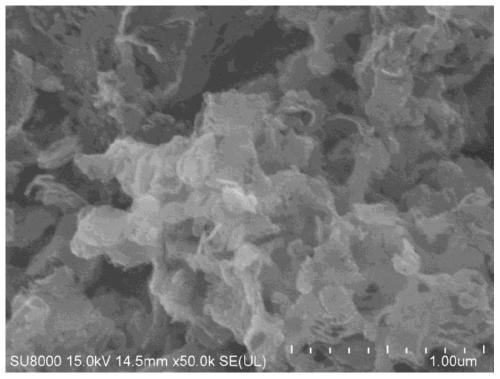

[0034] refer to figure 1 and 2 as shown, figure 1 It is the field emission scanning electron microscope topography figure of the original graphite phase carbon nitride sheet structure and porous structure of the gained example 1; figure 2 It is the m...

Embodiment 3

[0036] Repeat Example 2, with the following differences, the addition of montmorillonite is 0.5mg, 1.0mg, 5mg. Composite materials obtained with different ratios of Mt are recorded as 0.25% Mt / g-C 3 N 4 , 0.5%Mt / g-C 3 N 4 , 2.5% Mt / g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com