Mobile terminal component and preparation method thereof

A mobile terminal and component technology, applied in the field of mobile terminal components and their preparation, can solve problems such as mechanical properties decline, and achieve the effects of increasing surface area, improving roughness, and high bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

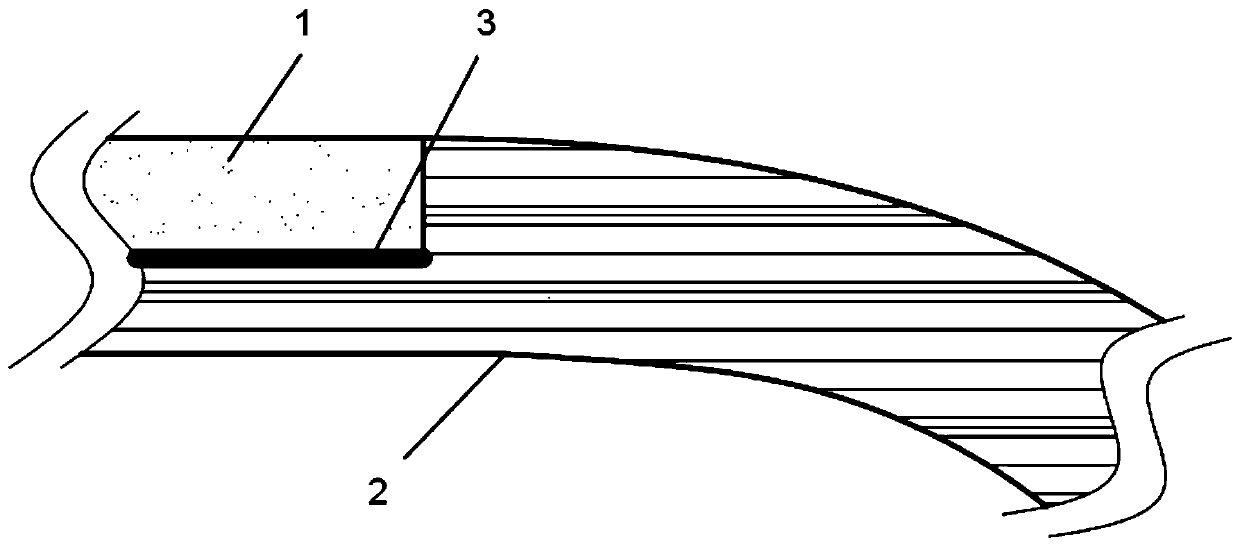

[0056] An embodiment of the mobile terminal component of the present invention, the mobile terminal component in this embodiment includes a ceramic component, a plastic component and an adhesive layer; the adhesive layer is used to connect the ceramic component and the plastic component; the ceramic component A gravel layer is provided on the surface in contact with the bonding layer, the particle size of the gravel in the gravel layer is 65 μm in D50, the roughness is 20 μm, and the gravel is white corundum sand; the ceramic component is black ceramic with a thickness of 0.5 mm Cover plate; the plastic component is PA material; the material of the bonding layer is a hot-melt acrylic resin, which is a mixture of acrylic resin with a molecular weight of 42,000 and acrylic resin with a molecular weight of 200,000, and acrylic resin with a molecular weight of 42,000 The mass ratio of the resin to the acrylic resin with a molecular weight of 200,000 is 1:9, and the dry film thickne...

Embodiment 2

[0063] An embodiment of the mobile terminal component of the present invention, the mobile terminal component in this embodiment includes a ceramic component, a plastic component and an adhesive layer; the adhesive layer is used to connect the ceramic component and the plastic component; the ceramic component A gravel layer is arranged on the surface in contact with the bonding layer, the particle size of the gravel in the gravel layer is 120 μm in D50, the roughness is 8 μm, and the gravel is white corundum sand and glass sand; the ceramic component is 0.5mm emerald Green ceramic cover plate; the plastic component is PPS material; the material of the bonding layer is hot-melt polyurethane resin, which is a mixture of polyurethane resin with a molecular weight of 49,000 and a polyurethane resin with a molecular weight of 210,000, and a molecular weight of 49,000 The mass ratio of the polyurethane resin with a molecular weight of 210,000 is: 1:6, the R value is 6, and the dry fi...

Embodiment 3

[0070] An embodiment of the mobile terminal component of the present invention, the mobile terminal component in this embodiment includes a ceramic component, a plastic component and an adhesive layer; the adhesive layer is used to connect the ceramic component and the plastic component; the ceramic component A gravel layer is provided on the surface in contact with the bonding layer, the particle size of the gravel in the gravel layer is 150 μm in D50, the roughness is 25 μm, and the gravel is glass sand and brown corundum sand; the thickness of the ceramic component is 0.5 mm The white ceramic cover plate; the plastic component is PC material; the material of the bonding layer is a hot-melt silane coupling agent, which is a silane coupling agent with a molecular weight of 52,000 and a silane coupling agent with a molecular weight of 260,000 The mass ratio of the silane coupling agent with a molecular weight of 52,000 to the silane coupling agent with a molecular weight of 260...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com