Method for broadening torque-constant frequency-variable speed regulation scope via Y type winding with tap connection

A technology of variable frequency speed regulation and winding taps, which is applied in the direction of control of generators, electronic commutation motor control, control systems, etc., can solve the problem of increasing system cost and control complexity, cannot expand the range of constant torque speed regulation, and increase semiconductor power Problems such as device pressure, to achieve the effect of expanding the range of constant torque frequency conversion speed regulation, significant benefits, and fewer switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

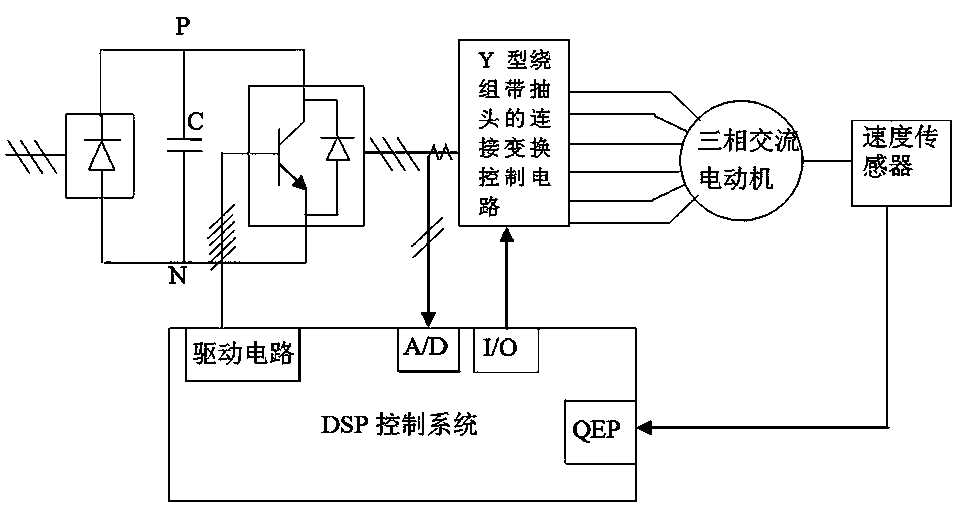

[0067] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

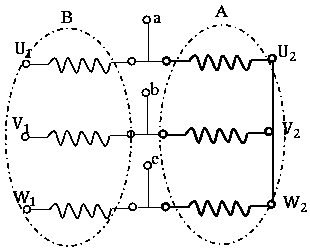

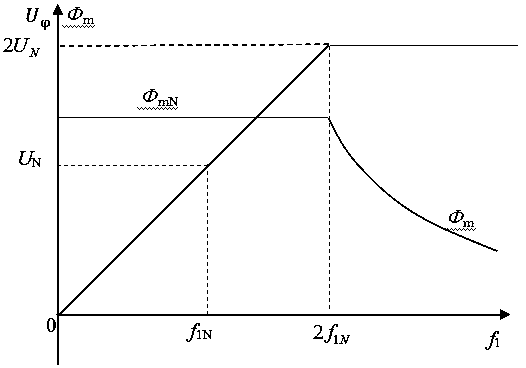

[0068] The invention proposes a technology combining the connection conversion of the winding with taps and the change of the conductor cross-section to realize the goal of expanding the range of constant torque speed regulation. The basic idea is to divide each phase of the Y-shaped three-phase winding into two parts with the same structure and number of turns, but different cross-sectional areas, and the two parts are connected in series, and a tap is drawn between them. When the motor voltage rises to the rated value with the frequency, the PWM power supply is transferred to the tap through the transfer switch, so that the part of the winding with a larger area is connected to the power supply, and the other part of the winding is disconnected from the power supply. As a result, the number of series turns of the winding is reduced by h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com