Method for determining minimum safety flow of turbine low-pressure cylinder

A minimum flow, low-pressure cylinder technology, applied in the direction of instrumentation, calculation, electrical digital data processing, etc., can solve the inaccurate determination of the peak-shaving depth of thermal power units, the inaccurate determination of the minimum flow rate of low-pressure cylinders, and the inability to fully utilize the peak-shaving potential of thermal power units And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Embodiment: determine the minimum safe flow of a certain 300MW steam turbine low-pressure cylinder through a method for determining the minimum safe flow of the low-pressure cylinder of the steam turbine, including the following steps:

[0101] (1) Model pre-processing: For a 300MW steam turbine unit, extract the blade data and operating parameters, and establish the final stage flow field of the unit's low-pressure cylinder and the solid structure model of the blade. The steps are as follows:

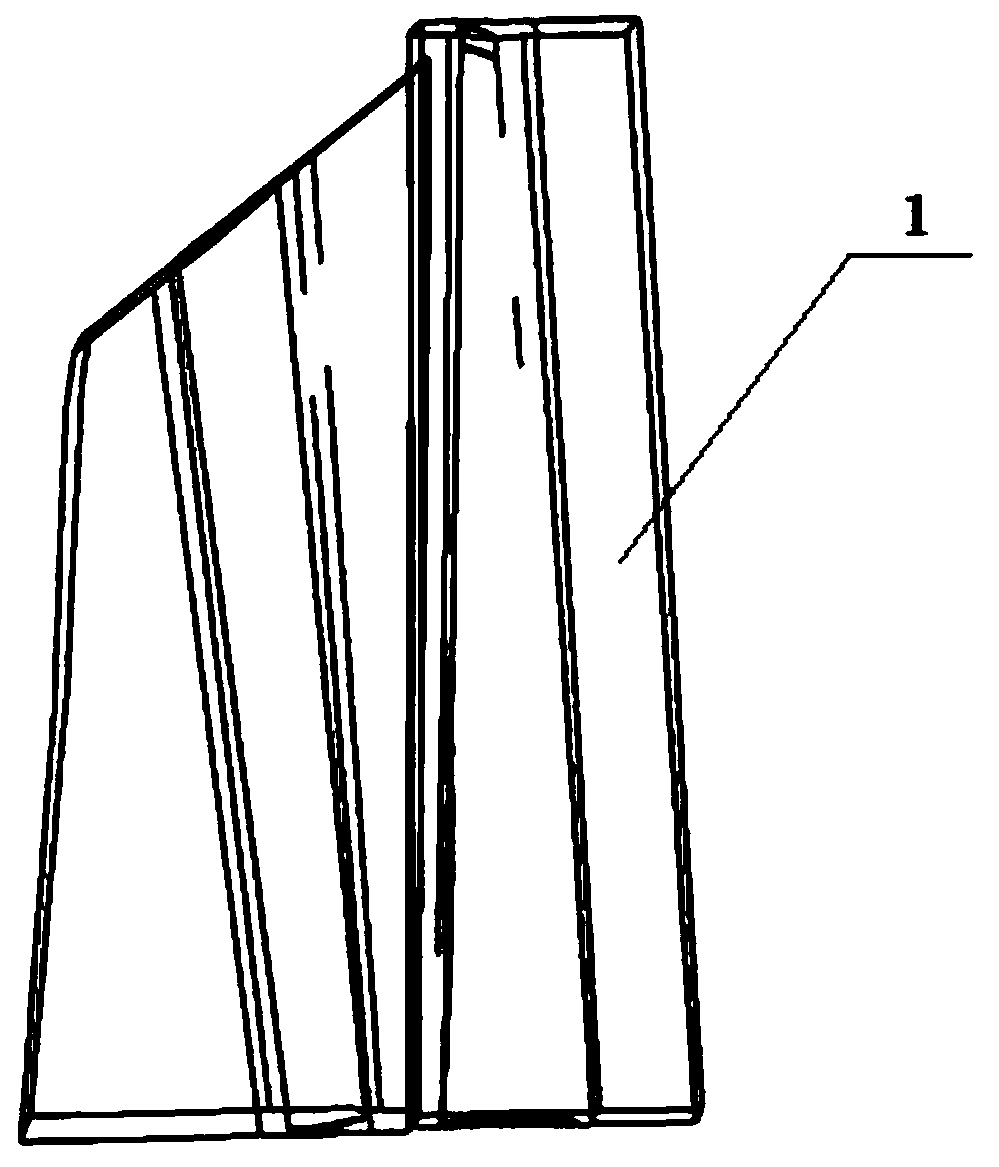

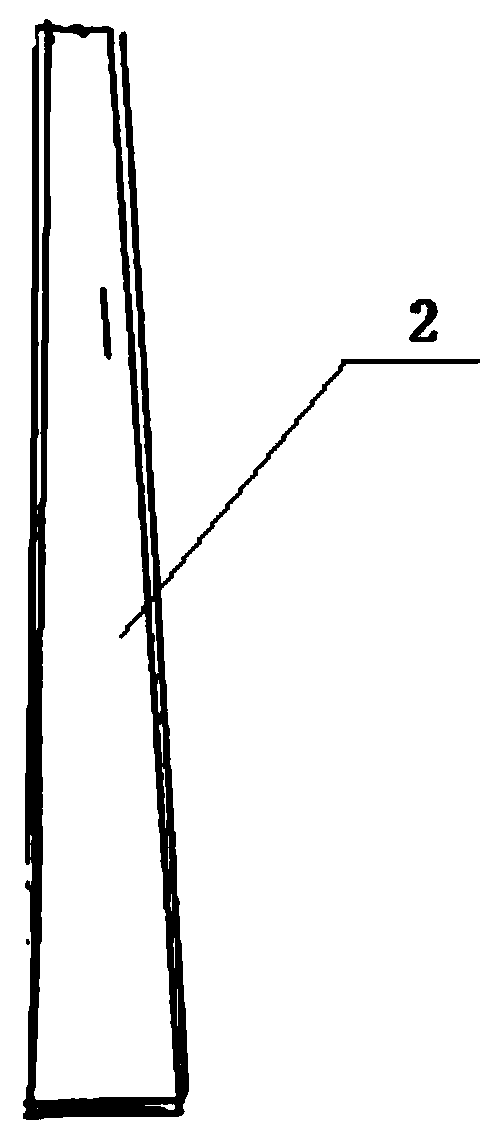

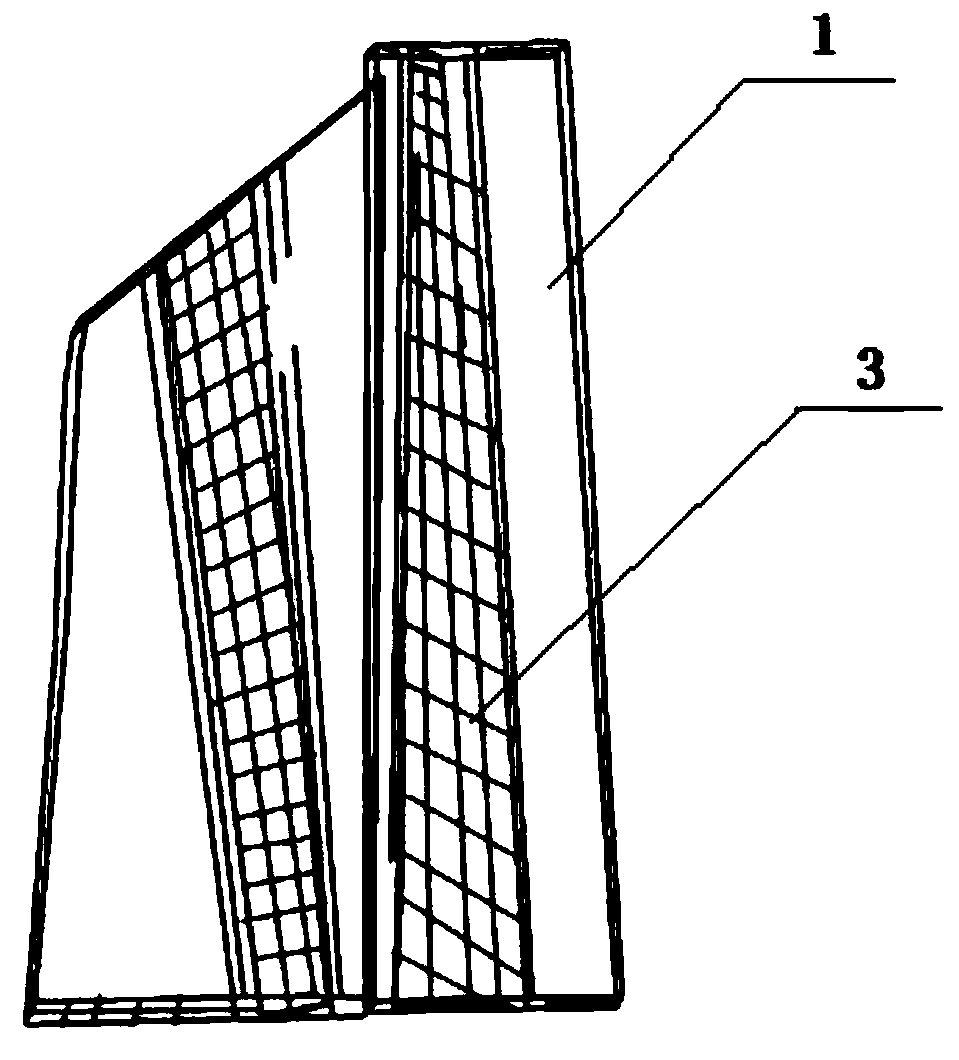

[0102] (1.1) Through the three-dimensional scanning of a 300MW steam turbine final stage blade model to form data points, set up in Gambit as attached figure 1 shown, the physical model and the attached figure 2 The moving blade structure model shown, the number of moving blades is 80, the number of stationary blades is 52, and the blade height is 906mm;

[0103] (1.2) Since the blade model is periodic, in order to save calculation time, a single-channel physical model is esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com