Heat distortion temperature measuring method for thermoplastic sealing stripes for furniture

A heat distortion temperature, thermoplastic technology, applied in the investigation stage/state change, etc., can solve the problems of complex and cumbersome measurement methods, inability to measure products, etc., and achieve the effect of saving test costs and test time, and simple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

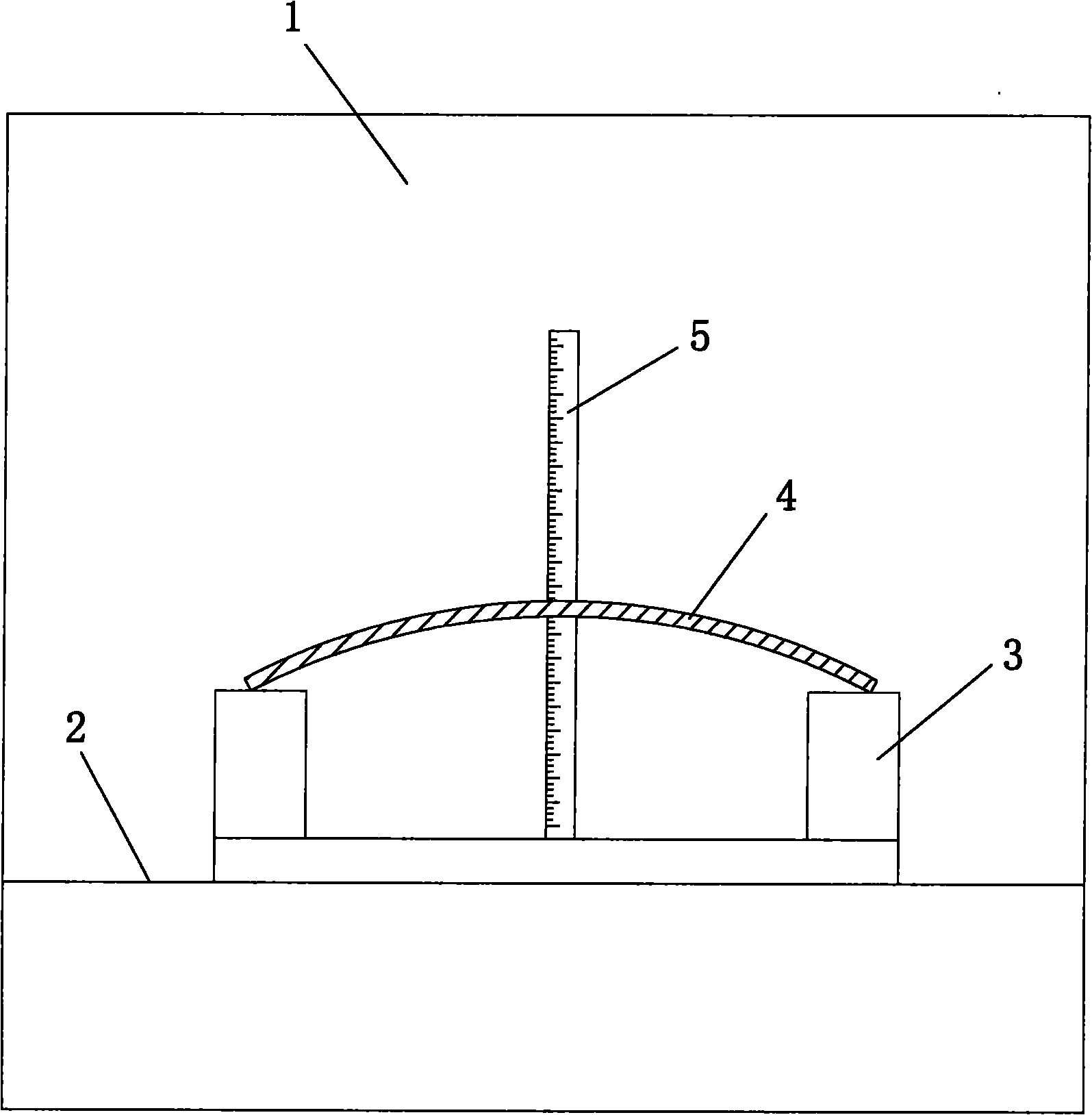

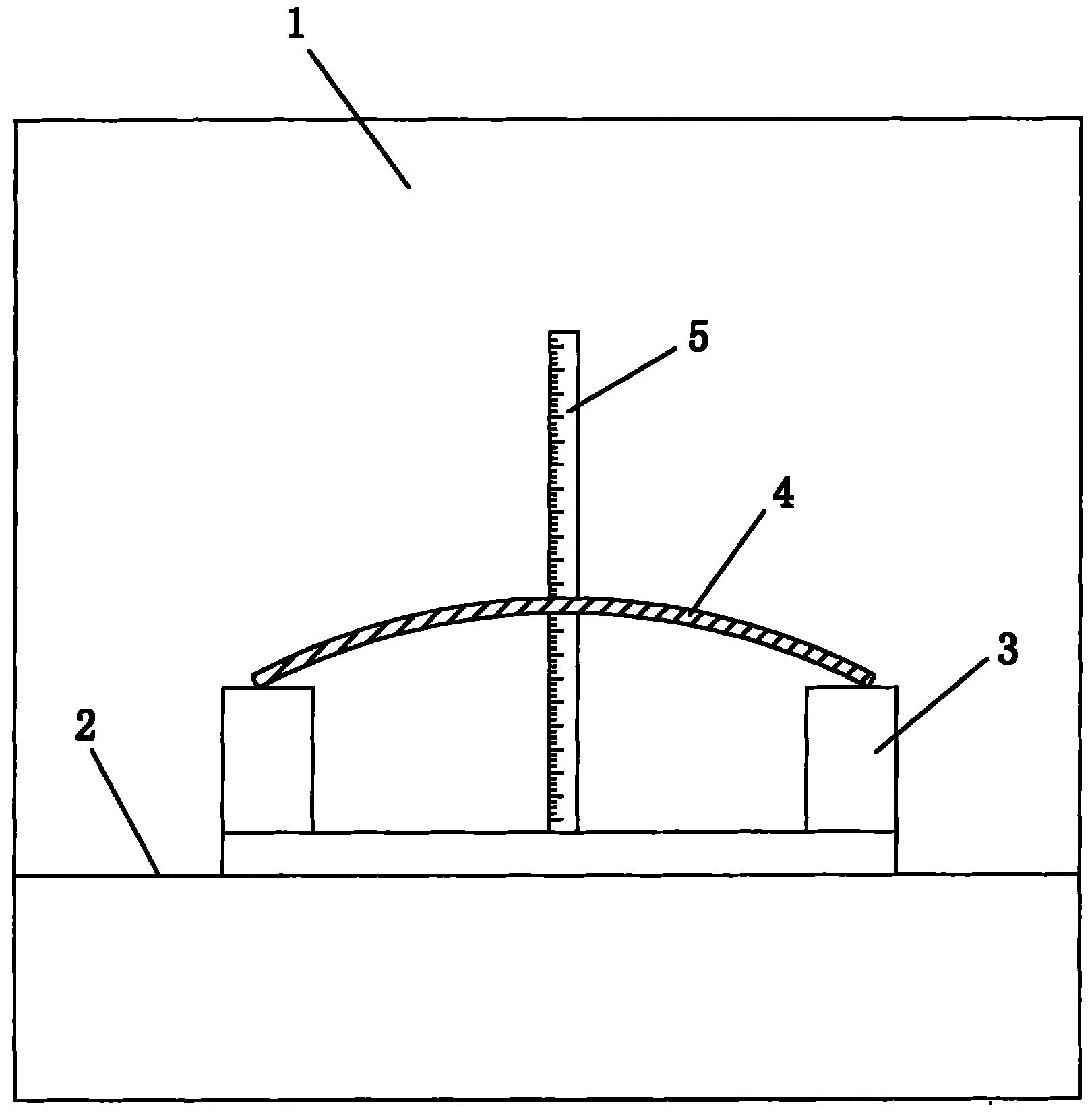

[0021] In this example, refer to figure 1 , the method for measuring the heat distortion temperature of the furniture thermoplastic edge banding, including a test process and a comparative test;

[0022] A. The test process is carried out in the following steps:

[0023] 1), prepare the circulating air oven 1, test bench, timer (not shown), wherein the test bench is composed of a support frame 2, a sample support table 3 and a scale 5, and the sample support table 3 and the scale bar 5 are fixed on the support frame 2 together to form the entire test bench;

[0024] 2), prepare 5 edge banding samples 4, of course, it can also be 3 or 4, and the length is 160-170mm;

[0025] 3), according to different samples, set the circulating air oven to the corresponding initial temperature, and put it into the test stand; the sample support platform 3 is placed on the support frame 2, and the sample support platform 3 includes two support units, two The distance between the support uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com