Method for controlling rotation of liquid drops after collision

A technology of rotating motion and controlling fluid, which is applied in fluid dynamics tests, testing of machine/structural components, measuring devices, etc., and can solve problems such as rough adjustment and inability to control precisely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

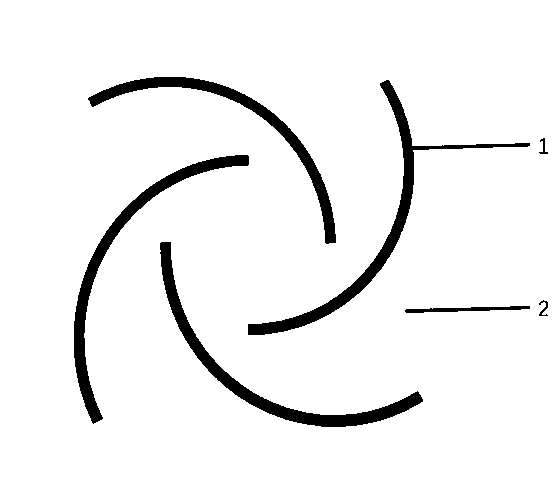

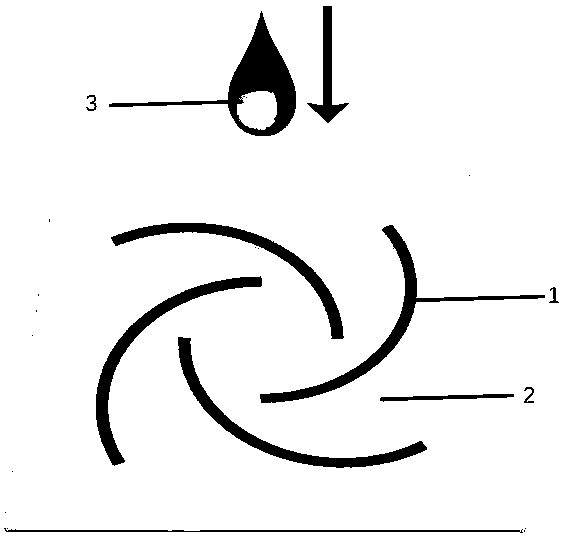

Method used

Image

Examples

Embodiment 1

[0024] Control the rotation and rebound behavior of water droplets after impact. The single crystal silicon wafer is cleaned, and the specific steps are as follows: ultrasonically clean the silicon wafer with acetone, ethanol and deionized water respectively. Then soak in 5% hydrofluoric acid aqueous solution for 3 minutes, 24% hydrofluoric acid / 0.5% silver nitrate mixed solution for 3 minutes, and 24% hydrofluoric acid / 5% hydrogen peroxide mixed solution for 2 hours. After taking it out, blow it dry with ultra-pure nitrogen, then immerse the single crystal silicon wafer in a methanol solution with a concentration of 1% 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane, let it stand for 5 minutes, and then use Drying with ultra-pure nitrogen, the obtained substrate has the properties of super-hydrophobic and ultra-low adhesion. A metal hollow mask is covered on the substrate, and a selective exposure treatment is carried out with an ultraviolet lamp. The area irradiated by light ...

Embodiment 2

[0026] The rotating droplet drives the substrate to rotate. Preparation of high-adhesion / hydrophobic-low-adhesion substrates: Ultra-thin aluminum sheets with a thickness of 50 μm were ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and then dried with high-purity nitrogen. Prepare Baker's solution: Mix 40 mL of concentrated hydrochloric acid, 2.5 mL of hydrofluoric acid, and 12 mL of deionized water. Immerse the aluminum piece in Baker's solution, take it out after 10 seconds, rinse it with deionized water quickly, and blow it dry with high-purity nitrogen. Place the aluminum sheet in a clean glass vacuum desiccator, place a glass slide in it, drop a drop of octadecyltrichlorosilane on the glass slide with a dropper, evacuate it with a vacuum pump for 30 minutes, and then place it at 80 Stand still in the forced air drying oven at 100°C for 2 hours. After the treatment, the contact angle of the aluminum sheet is 165 degrees, and the adhesion for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com