Loop heat pipe with pipe diameter of heat absorption part larger than pipe diameter of condensation part

A loop heat pipe and evaporator technology, applied in the field of heat pipes, can solve problems such as uneven separation of partition devices, excessive local temperature, and narrow area of space A, so as to avoid uneven partition, improve heat exchange effect, and improve steady flow effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0062] In this article, if there are no special instructions, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

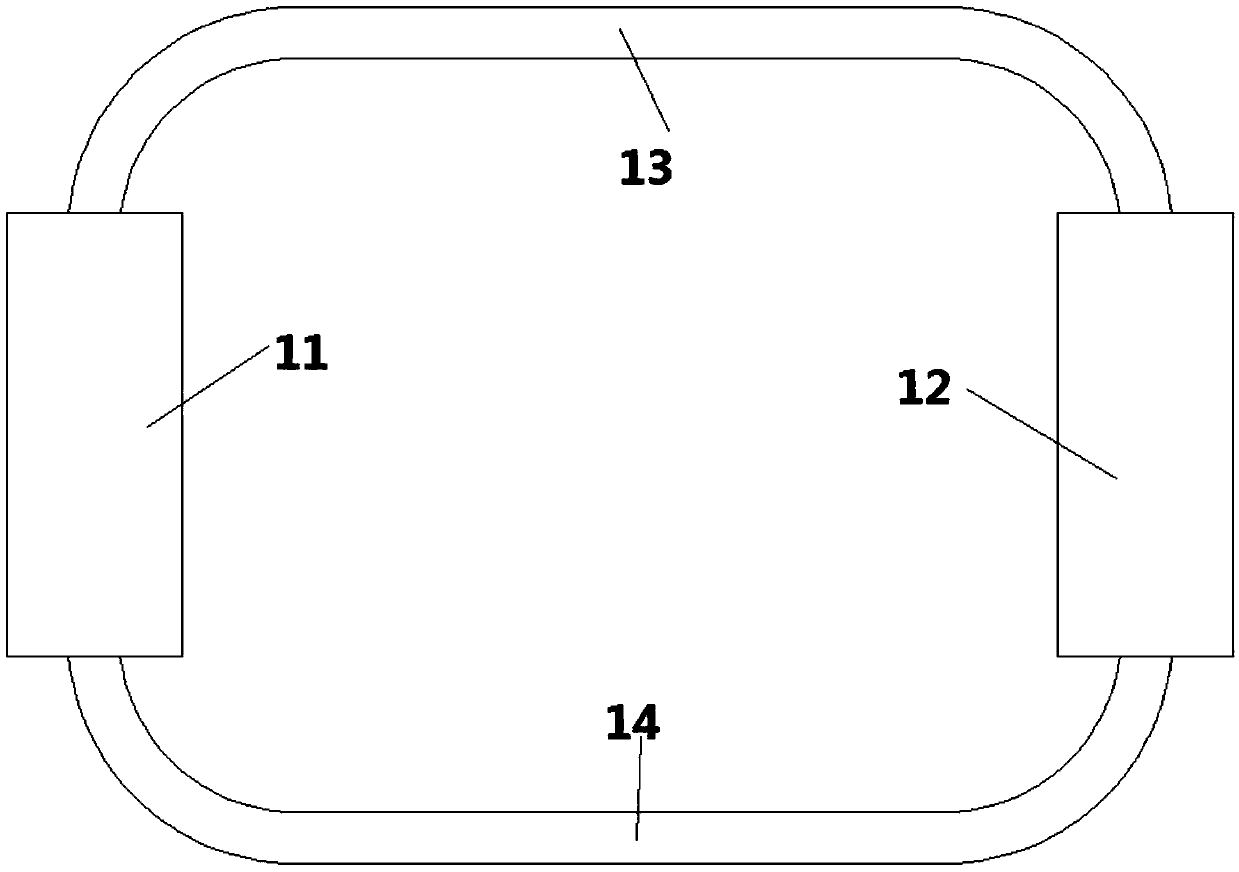

[0063] Such as figure 1 The loop heat pipe 1 shown includes an evaporation part 11, a condensation part 12, and a heat insulation part 13 and a return part 14 connecting the evaporation part and the condensation part. The fluid absorbs heat and evaporates in the evaporation part 11 and enters the condensation part through the heat insulation part 13 12. The condensed fluid is condensed after heat exchange in the condensing part 12, and the condensed fluid returns to the evaporating part 11 through the return pipe 14. Preferably, the return part is also insulated.

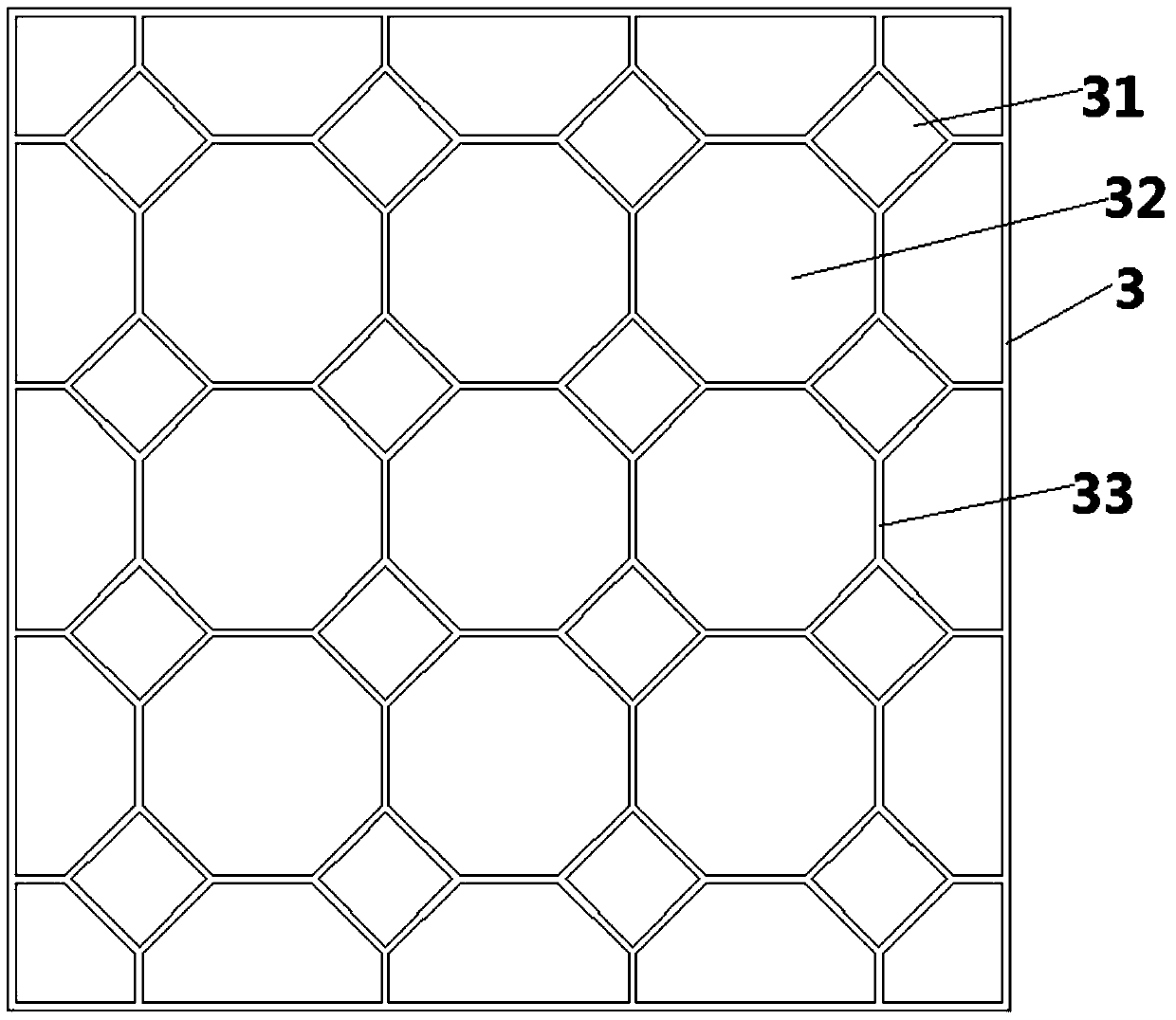

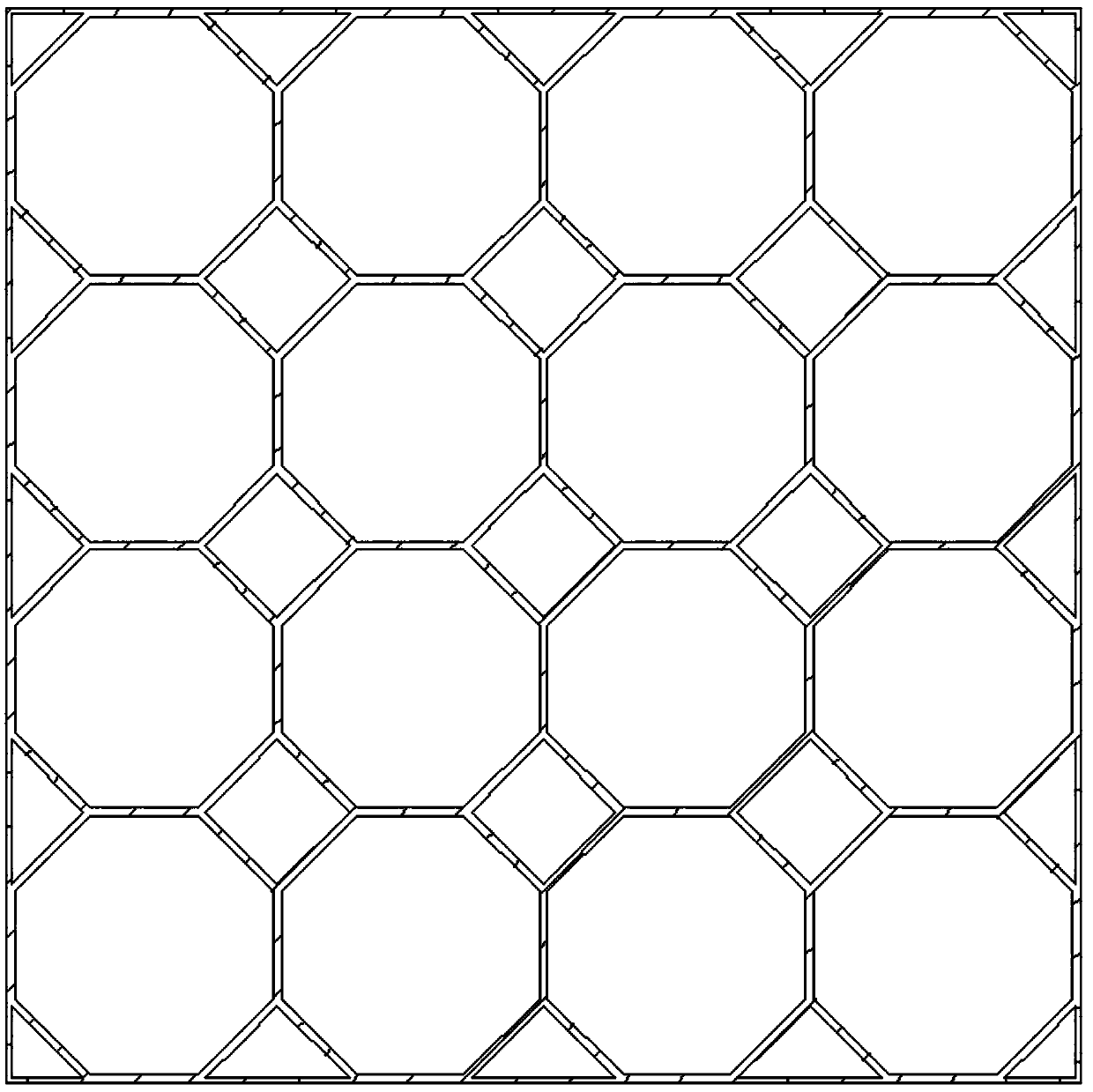

[0064] As an improvement, the evaporator includes a heat absorption tube, and a partition device 3 is arranged in the heat absorption tube....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com