Composite photoanode and preparation method thereof

A technology of composite materials and photoanodes, which is applied in the fields of nanomaterials, semiconductor materials and electrochemistry, can solve problems affecting photoelectric performance and poor conductivity, and achieve the effects of enhancing photoelectric performance, improving photoelectric performance, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 prepares α-Fe 2 o 3 Nanocrystalline

[0016] 1. Preparation of Fe(acac) by electrospinning 3 / PVP composite nanofiber

[0017] Take 0.6g of PVP with a molecular weight of 30000-40000 into a 20mL strain bottle, then put it into a magnet with a width of about 1.5cm, then add 4.5mL of ethanol solution, and stir on a magnetic stirrer. After stirring for 12 hours (or using the hot solution method, that is, heat and stir until a clear and transparent solution appears), add 5.25mL of glacial acetic acid to prevent Fe(acac) 3 Hydrolyze, continue to stir until the solution is uniform, then add 1.2g of Fe(acac) 3 Just mix well. Inject the evenly stirred liquid into a 5mL syringe, then fix the syringe in a large electrospinning machine, cover the bottom of the syringe with tin foil as a receiver, set the voltage to 17.5kV, flow rate to 3mL / h, and adjust the humidity to below 40%.

[0018] 2. α-Fe 2 o 3 Preparation of nanocrystals:

[0019] Take 16mg Fe(acac)...

Embodiment 2

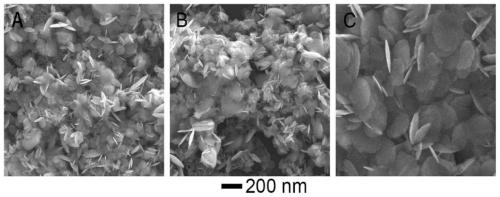

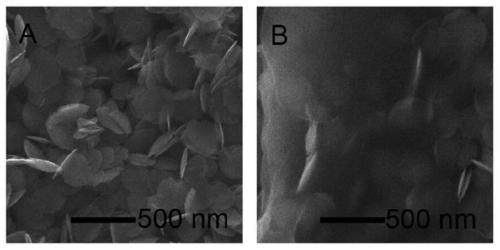

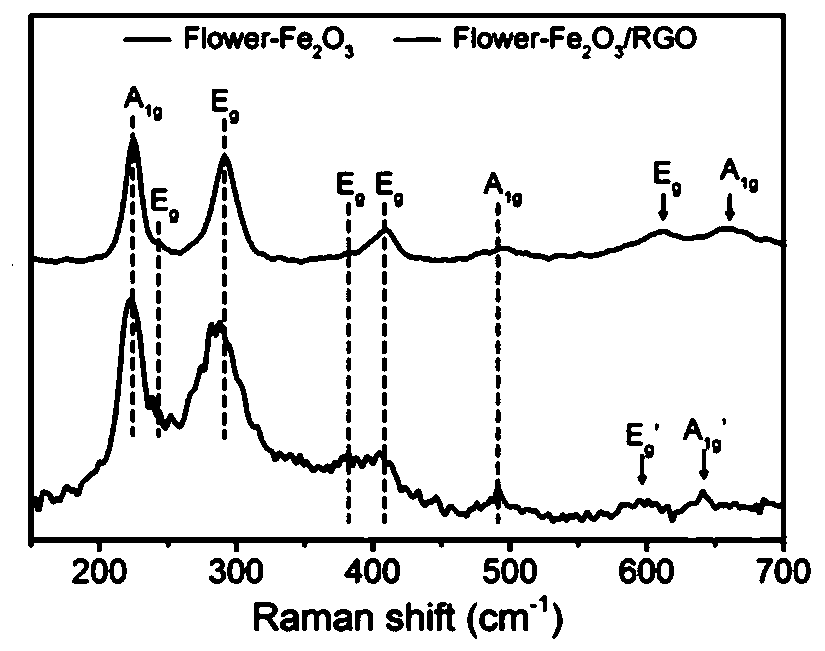

[0020] Example 2 Preparation of α-Fe with GO doping amount of 1% 2 o 3 / RGO Composite Nanomaterials

[0021] 1. Preparation of Fe(acac) by electrospinning 3 / PVP composite nanofiber:

[0022] Take 0.6g of PVP with a molecular weight of 30000-40000 into a 20mL strain bottle, then put it into a magnet with a width of about 1.5cm, then add 4.5mL of ethanol solution, and stir on a magnetic stirrer. After stirring for 12 hours (or using the hot solution method, that is, heat and stir until a clear and transparent solution appears), add 5.25mL of glacial acetic acid to prevent Fe(acac) 3 Hydrolyze, continue to stir until the solution is uniform, then add 1.2g of Fe(acac) 3 Just mix well. Inject the evenly stirred liquid into a 5mL syringe, then fix the syringe in a large electrospinning machine, cover the bottom of the syringe with tin foil as a receiver, set the voltage to 17.5kV, flow rate to 3mL / h, and adjust the humidity to below 40%.

[0023] 2. Improved Hummers method t...

Embodiment 3

[0032] Example 3 Preparation of α-Fe with GO doping amount of 5% 2 o 3 / RGO Composite Nanomaterials

[0033] 1. Preparation of Fe(acac) by electrospinning 3 / PVP composite nanofiber:

[0034] Take 0.6g of PVP with a molecular weight of 30000-40000 into a 20mL strain bottle, then put it into a magnet with a width of about 1.5cm, then add 4.5mL of ethanol solution, and stir on a magnetic stirrer. After stirring for 12 hours (or using the hot solution method, that is, heat and stir until a clear and transparent solution appears), add 5.25mL of glacial acetic acid to prevent Fe(acac) 3 Hydrolyze, continue to stir until the solution is uniform, then add 1.2g of Fe(acac) 3 Just mix well. Inject the evenly stirred liquid into a 5mL syringe, then fix the syringe in a large electrospinning machine, cover the bottom of the syringe with tin foil as a receiver, set the voltage to 17.5kV, flow rate to 3mL / h, and adjust the humidity to below 40%.

[0035] 2. α-Fe 2 o 3 Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com