Water-based inorganic quenching medium

A quenching medium and inorganic technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of peculiar smell in the production process, difficult on-site maintenance, complex raw materials and preparation process, etc., and achieve low overall cost and small quenching stress , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] (1) Composition and proportion of new water-based inorganic quenching medium

[0029] CaCl 2 :28~35wt%, ZnCl 2 :18~22wt%, MgCl 2 :5~8wt%, H 2 O margin. Among them, the three inorganic salts are anhydrous salts with a purity greater than 95%.

[0030] (2) Preparation of new water-based inorganic quenching medium

[0031] Sequentially add the corresponding mass percentage of CaCl in water 2 , ZnCl 2 and MgCl 2 (both are anhydrous inorganic salts), and stir while adding, until the above-mentioned various inorganic salts are completely dissolved in water.

[0032] (3) Physical and chemical properties of the new water-based inorganic quenching medium

[0033] Odorless, dark yellow, no sediment, density 1.49g / cm 3 , the boiling point is 120°C, and the pH value is 5~6 (weakly acidic).

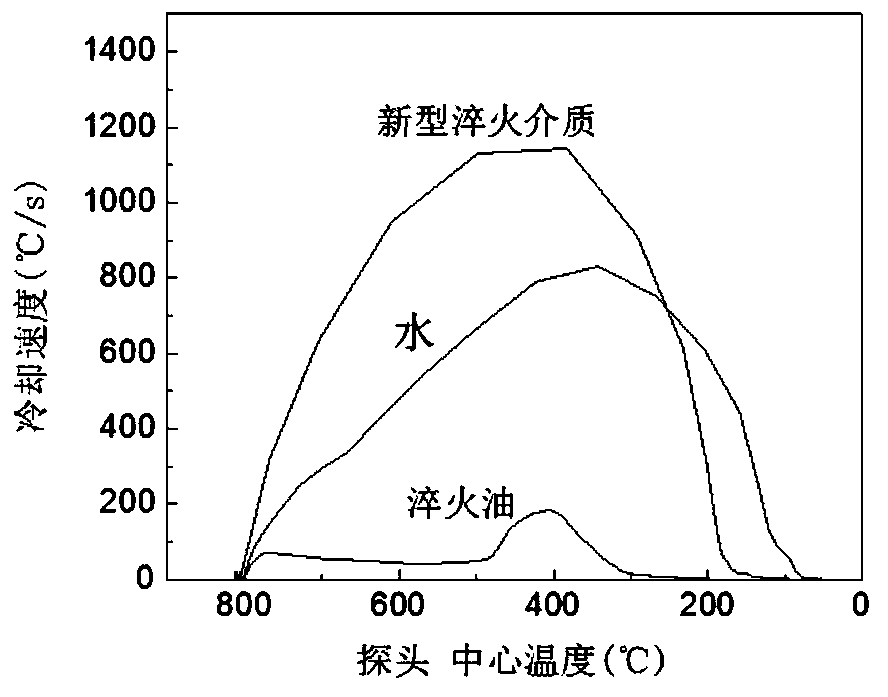

[0034] (4) Cooling characteristics of new water-based inorganic quenching medium

[0035] The instrument for measuring the cooling characteristic curve of the quenching medium is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com