A method for rapidly dissolving chitosan by acidic ionic liquid at low temperature

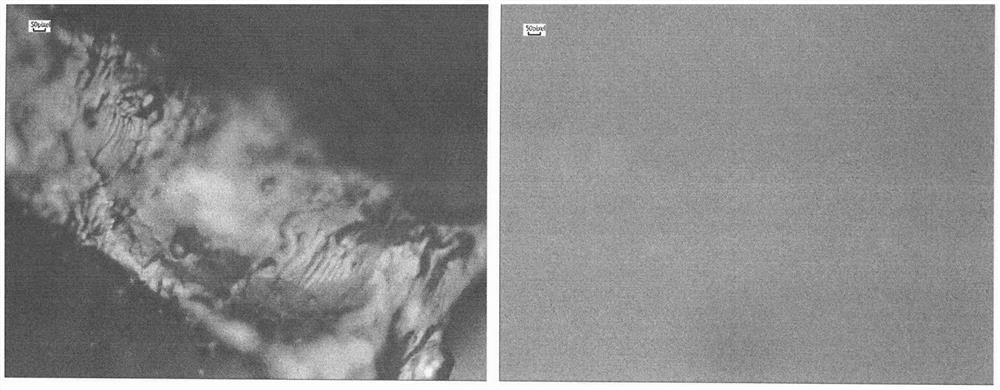

A technology of acidic ionic liquid and chitosan, which is applied in the preparation of acidic ionic liquid, and in the field of rapid dissolution of chitosan by acidic ionic liquid at low temperature, can solve the problems of low dissolution efficiency, chitosan hydrolysis, and long dissolution time, and achieve dissolution The effect of fast speed, low dissolution temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

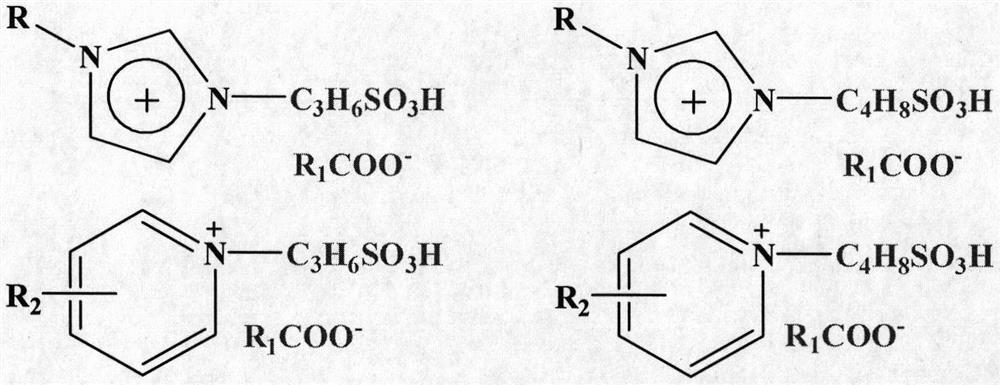

[0036] 1-Methyl-3-(propyl-3-sulfonic acid) imidazolium salt (mPSO 3 )Synthesis

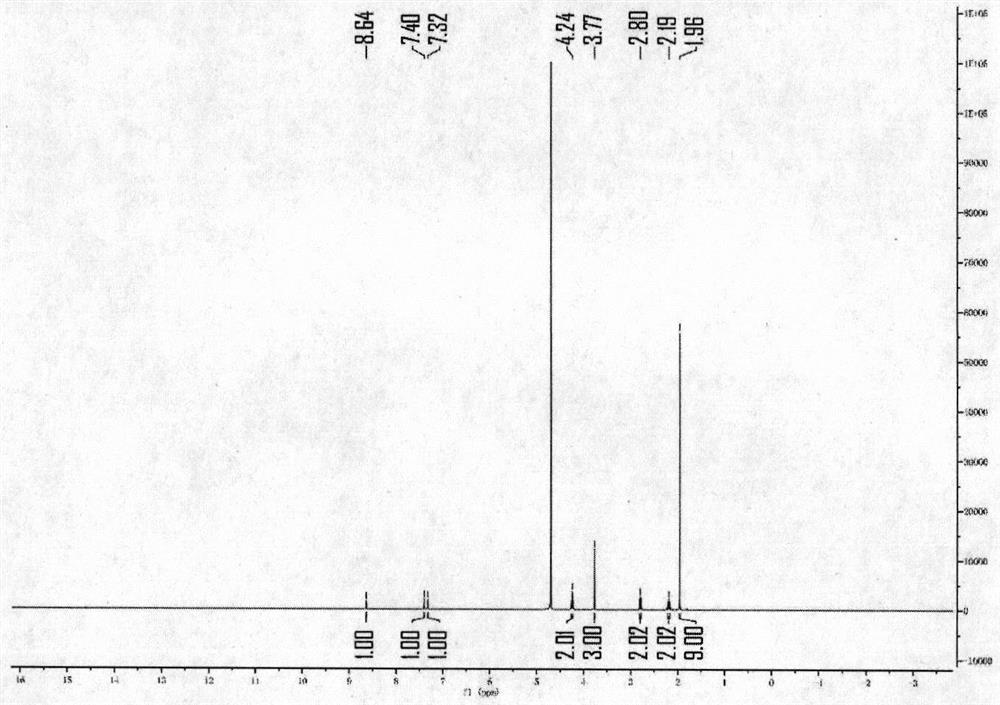

[0037] Add 80 mL of dichloromethane to the four-necked flask, add 0.105 mol of propyl sultone, cool down in an ice bath under constant stirring, slowly add 0.1 mol of N-methylimidazole dropwise at a constant pressure, slowly heat up after dropping, and react at room temperature for 2 h, Suction filtration, wash the solid three times with ethyl acetate, remove excess propyl sultone and dichloromethane, dry at 80 °C for 2 h, the obtained white solid is mPSO 3 , the yield was 99%, the melting point was 227 °C, and the structure was confirmed by H NMR;

[0038] The reaction equation is as follows:

[0039]

[0040] Synthesis of 1-methyl-3-(propyl-3-sulfonic acid)imidazole acetate (mPSAc)

[0041] The first step product (mPSO 3 ) and acetic acid (mol ratio of 1: 3) were added to the four-necked flask, stirred at room temperature, and the mixture gradually formed a homogeneous viscous liquid, whi...

Embodiment 2

[0049] 1-Butyl-3-(propyl-3-sulfonic acid)imidazolium salt (bPSO 3 )Synthesis

[0050] Add 80 mL of dichloromethane to the four-necked flask, add 0.105 mol of propyl sultone, cool down in an ice bath with constant stirring, slowly add 0.1 mol of N-butylimidazole dropwise at a constant pressure, slowly heat up after dropping, and react at room temperature for 2 h, Suction filtration, wash the solid 3 times with ethyl acetate, remove excess propyl sultone and dichloromethane, dry at 80 °C for 2 h, the obtained white solid is bPSO 3 , the yield was 99%, the melting point was 179 °C, and the structure was confirmed by H NMR;

[0051]

[0052] Synthesis of 1-butyl-3-(propyl-3-sulfonic acid)imidazole acetate (bPSAc)

[0053] The first step product (bPSO 3 ) and acetic acid (mol ratio of 1: 3) were added to the four-necked flask, stirred at room temperature, and the mixture gradually formed a homogeneous viscous liquid, which was an acidic ionic liquid (bPSAc), the yield was 100...

Embodiment 3

[0061] Synthesis of 1-methyl-3-(butyl-4-sulfonic acid) imidazolium salt (mBSO3)

[0062] Add 80 mL of dichloromethane to the four-necked flask, add 0.105 mol of butyl sultone, cool down in an ice bath with constant stirring, slowly add 0.1 mol of N-methylimidazole dropwise at a constant pressure, slowly heat up after dropping, and react at 25 °C 3h, suction filtration, wash the solid 3 times with ethyl acetate, remove excess butyl sultone and dichloromethane, dry, and the obtained white solid is mBSO 3 , the yield was 98%, the melting point was 216 °C, and the structure was confirmed by hydrogen NMR.

[0063] The product structure is as follows:

[0064]

[0065] Synthesis of 1-methyl-3-(butyl-4-sulfonic acid)imidazole acetate (mBSAc)

[0066] The first step product (mBSO 3 ) and acetic acid (mol ratio of 1: 3) were added to the four-necked flask, stirred at room temperature, and the mixture gradually formed a homogeneous viscous liquid, which was an acidic ionic liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com