Defoamer containing silicone oil and epoxidized soybean oil and preparation method thereof

A technology of epoxidized soybean oil and defoamer, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as complex processes, and achieve simple preparation process, wide application range, and excellent defoaming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

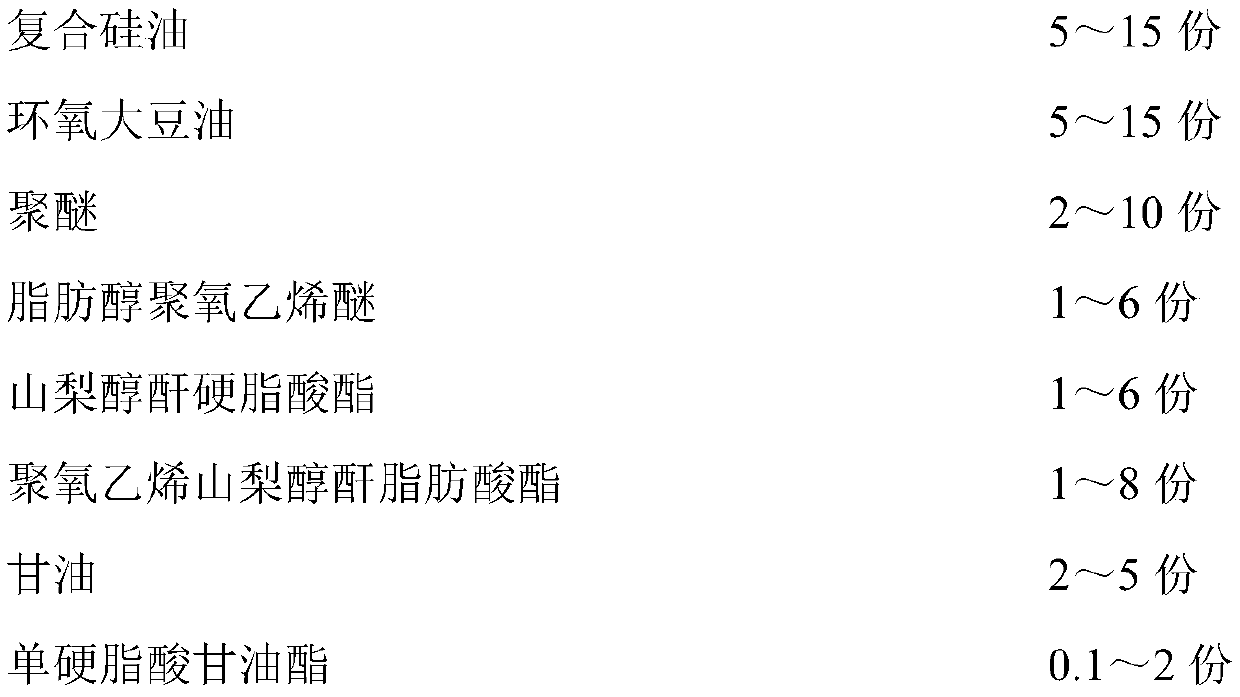

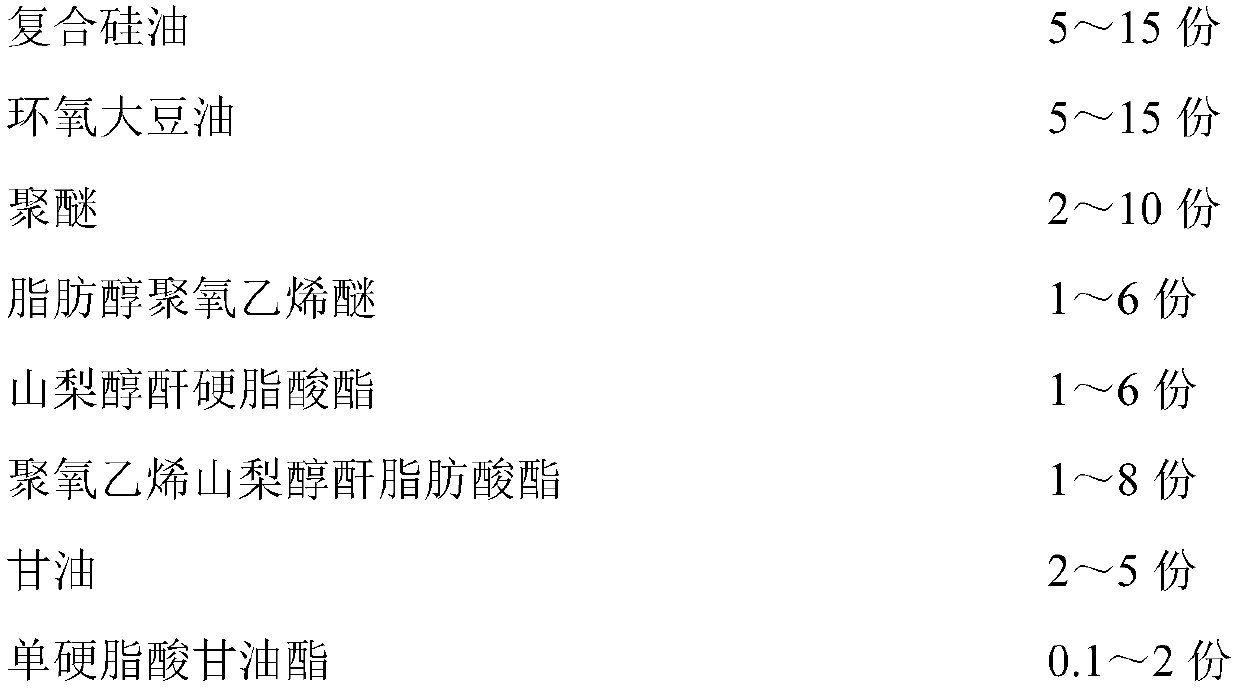

Method used

Image

Examples

Embodiment 1

[0023] Put simethicone oil and silicon dioxide with a viscosity of 1000cs into the reaction kettle at a mass ratio of 100:2, stir slowly, raise the temperature to 160°C, and continue stirring for 3 hours to obtain a composite silicone oil.

[0024] Add 10 parts of the above compound silicone oil, 10 parts of epoxy soybean oil, 6 parts of polyether, 5 parts of fatty alcohol polyoxyethylene ether, 1 part of sorbitan stearate (Span 60), polyoxyethylene sorbitan Put 1 part of fatty acid ester (Tween 80), 2 parts of glycerin and 0.2 part of glycerol monostearate in a reaction kettle, raise the temperature to 60° C., and stir for 0.5 h. Add the remaining amount of water, and then stir rapidly for 45min. Finally, use an emulsification pump to emulsify to obtain defoamer 1#.

Embodiment 2

[0026] Put simethicone oil with a viscosity of 300cs, simethicone oil with a viscosity of 3000cs, and silicon dioxide in a mass ratio of 60:40:2.5 into the reaction kettle, stir slowly, raise the temperature to 180°C, and continue stirring for 3.5h to obtain a composite silicone oil.

[0027] Add 8 parts of the above compound silicone oil, 12 parts of epoxy soybean oil, 3 parts of polyether, 6 parts of fatty alcohol polyoxyethylene ether, 2 parts of sorbitan stearate (Span 60), polyoxyethylene sorbitan Put 2 parts of fatty acid ester (Tween 80), 2 parts of glycerin and 0.1 part of glycerol monostearate in a reaction kettle, raise the temperature to 50°C, and stir for 1 hour. Add the remaining amount of water, and then stir rapidly for 1h. Finally, emulsify with an emulsification pump to obtain defoamer 2#.

Embodiment 3

[0029] Put simethicone oil with a viscosity of 300cs, simethicone oil with a viscosity of 3000cs and silicon dioxide into the reaction kettle at a mass ratio of 60:40:5, stir slowly, heat up to 180°C, and continue stirring for 4 hours to obtain a composite silicone oil.

[0030] Add 6 parts of the above compound silicone oil, 14 parts of epoxy soybean oil, 3 parts of polyether, 6 parts of fatty alcohol polyoxyethylene ether, 2 parts of sorbitan stearate (Span 60), polyoxyethylene sorbitan Put 2 parts of fatty acid ester (Tween 80), 2 parts of glycerin and 0.1 part of glycerol monostearate in a reaction kettle, raise the temperature to 70°C, and stir for 1 hour. Add the remaining amount of water, and then stir rapidly for 1.5h. Finally, emulsify with an emulsification pump to obtain defoamer 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com