Inline structure and production process of a thin film photovoltaic module

A thin-film photovoltaic module and laser scribing technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of large resistance, shading, and large dead area, and achieve low resistance, simple preparation process, and utilization per unit area. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

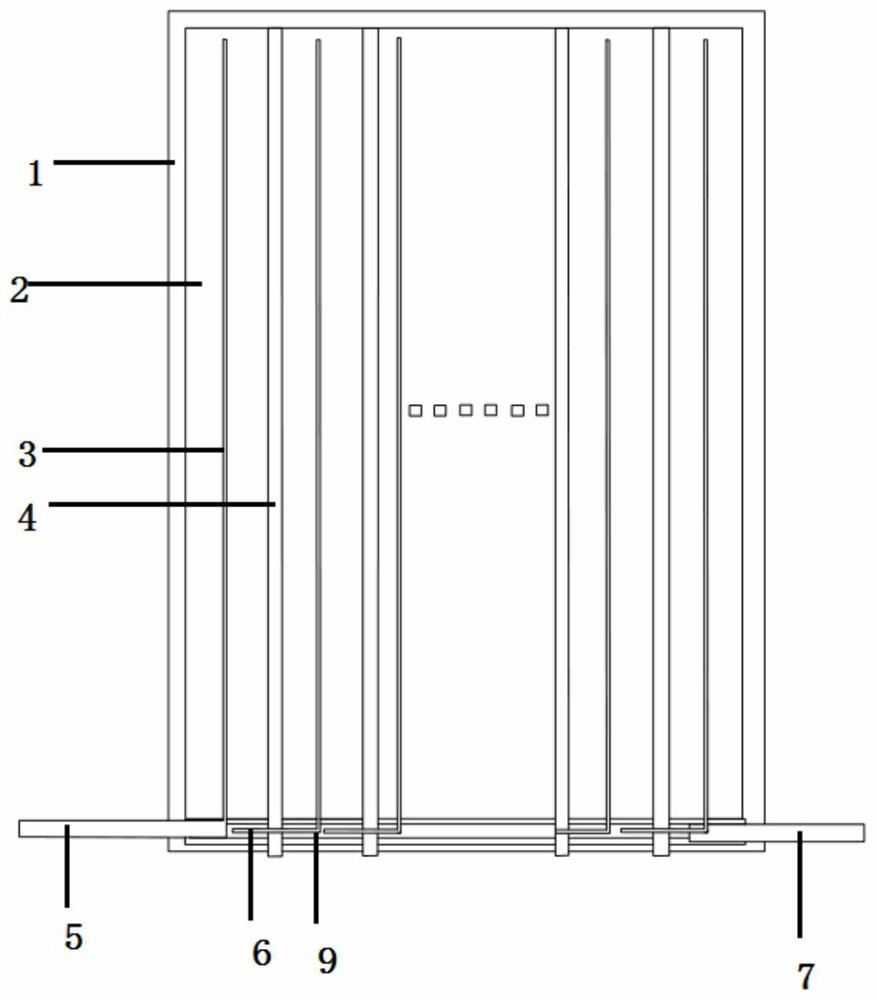

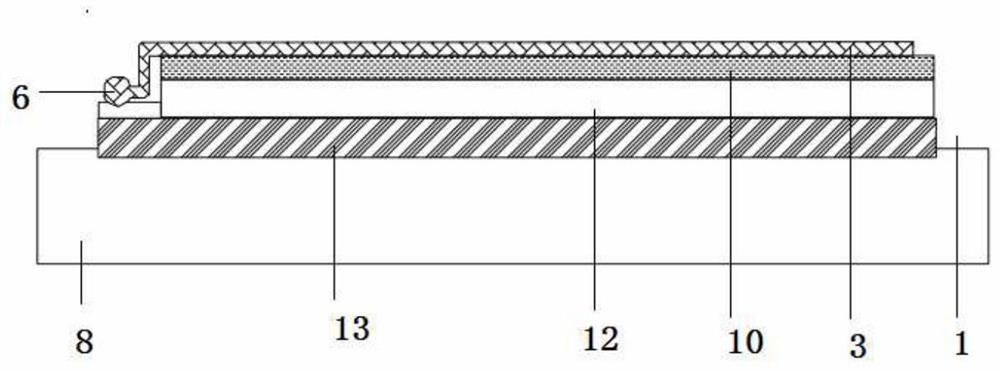

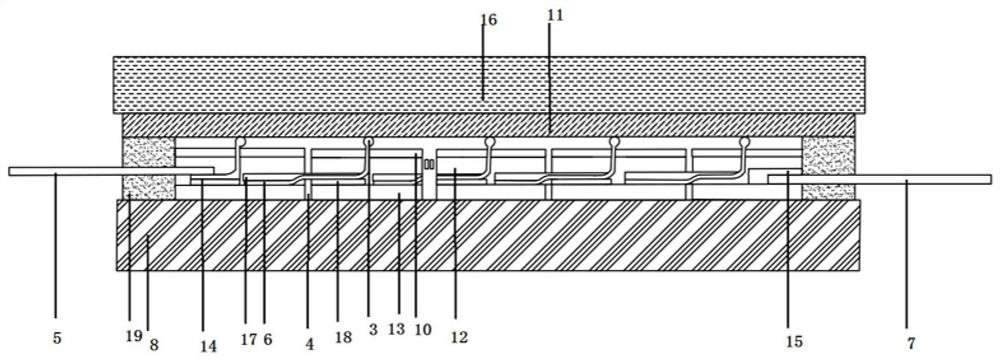

[0030] Example 1, such as figure 1 , figure 2 , image 3 As shown, the inline structure of the thin film photovoltaic module includes a substrate layer 8, a back conductive layer 13, an absorption layer 12, and a transparent conductive layer 10 arranged in sequence from bottom to top, and a laser scribed groove 4 is laser-marked on the thin-film stack The depth of the laser scribed groove 4 reaches the substrate layer 8, which is used to divide the battery into several sub-cells 2. The width of the scribed groove 4 is 25 μm or 150 μm, preferably 100 μm. If the scribed groove 4 is too wide, the dead zone is too large. Too narrow can easily lead to short circuit phenomenon; on the four sides of the battery as a whole, there is an edge laser scribe area 1 that reaches the depth of the substrate layer 8, and the edge laser scribe penetrates the transparent conductive layer 10, the absorption layer 12 and the back conductive layer 13 until the substrate layer 8, so as to effecti...

Embodiment 2

[0034] Embodiment 2, the present invention also provides a production process of the inline structure of the thin film photovoltaic module, comprising the following steps:

[0035] S1 deposits the back conductive layer 13, the absorption layer 12 and the transparent conductive layer 10 sequentially on the substrate layer 8, and the preparation of the entire thin film stack can be deposited continuously, which avoids the frequent contact between each film layer due to air contact during the preparation of each layer of thin film. Contact causes oxidation or contamination, and ensures good bonding between the film layers in a continuous vacuum environment. The substrate layer 8 can be made of materials such as stainless steel, glass or polyester; the back conductive layer 13 is used as the positive electrode of the battery, the transparent conductive layer 10 is used as the negative electrode of the battery, and the absorbing layer 12 is the core absorbing layer of the battery P~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com