A spiral three-dimensional oil coke or pitch conveying and cooling device and its design method and application

A cooling device and oil coal coke technology, applied in the field of oil coal coke and asphalt cooling devices, can solve the problems of low utilization rate per unit area and waste of floor space in the factory area, saving floor space, saving factory floor space, using rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, further description will be given below in conjunction with the accompanying drawings and specific embodiments.

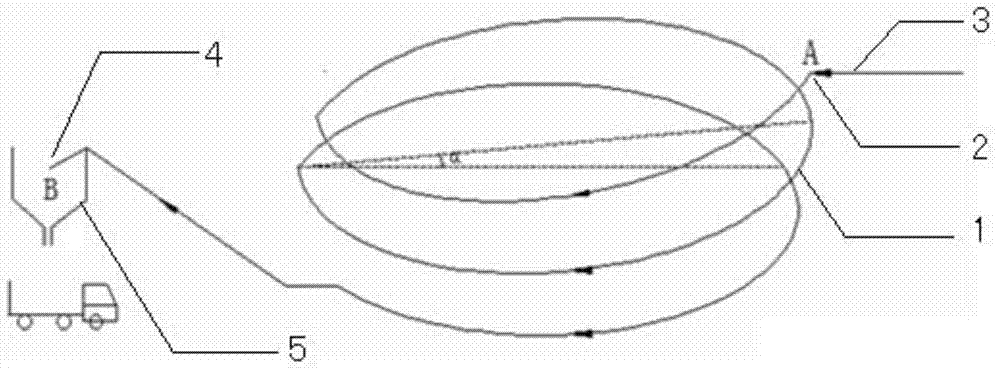

[0025] figure 1 It is a schematic diagram of an embodiment of a spiral three-dimensional oil coke or asphalt conveying and cooling device of the present invention. like figure 1 As shown, this embodiment includes a conveyor belt 1 for transporting oil coke or asphalt. The conveyor belt 1 is arranged in a spiral three-dimensional descending manner. Connected, the bottom end is the discharge port 4, with a spiral descending inclination angle α, which is 15° compared with the horizontal plane. The conveyor belt 1 has a width of 2.5m, a length of 400m, and a conveying speed of 1.0m / s. The device also includes a lower hopper 5, which is connected to the bottom of the conveyor belt 1. The lower hopper 5 is a cylindrical container with an open upper end, has a conical bottom, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com