Air cooling coupled heating furnace kiln smoke discharging deep condensate water demisting system

A heating furnace and depth technology, which is applied in the field of air-cooled coupled heating furnace and kiln smoke exhaust deep condensation water mist elimination system, can solve the problems of poor energy saving and environmental protection, and insufficient fog elimination, so as to improve water saving benefits and ensure mist elimination Effects of fog reliability and condensing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

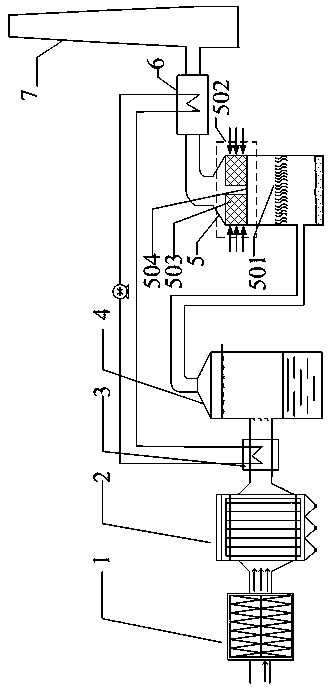

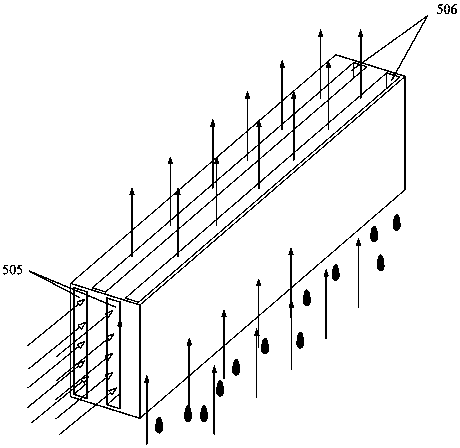

[0037] Such as Figure 1 to Figure 2 As shown, an air-cooled coupled heating furnace exhaust smoke deep condensation and fog elimination system in this embodiment includes a first-stage waste heat recovery heat exchanger 1, a dust collector 2, a desulfurization tower 3, and a waste heat deep recovery heat exchange device 4, flue gas condenser 5, heater 6 and exhaust chimney 7.

[0038] Among them, the first-level waste heat recovery heat exchanger 1 is used to recover the waste heat of the flue gas. After the flue gas is discharged from the kiln, it first passes through the first-level waste heat recovery heat exchanger. The recovered heat can be used in the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com