Water-cooled rotary grate straw bale-fired semi-gasified direct-fired atmospheric pressure hot-water boiler

A technology of rotary grate and hot water boiler, applied in the direction of rotary grate, grate, incinerator, etc., which can solve the problems of slow combustion speed, noise pollution, short flue gas flow, etc., so as to save intermediate processing and molding links, reduce heat loss, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

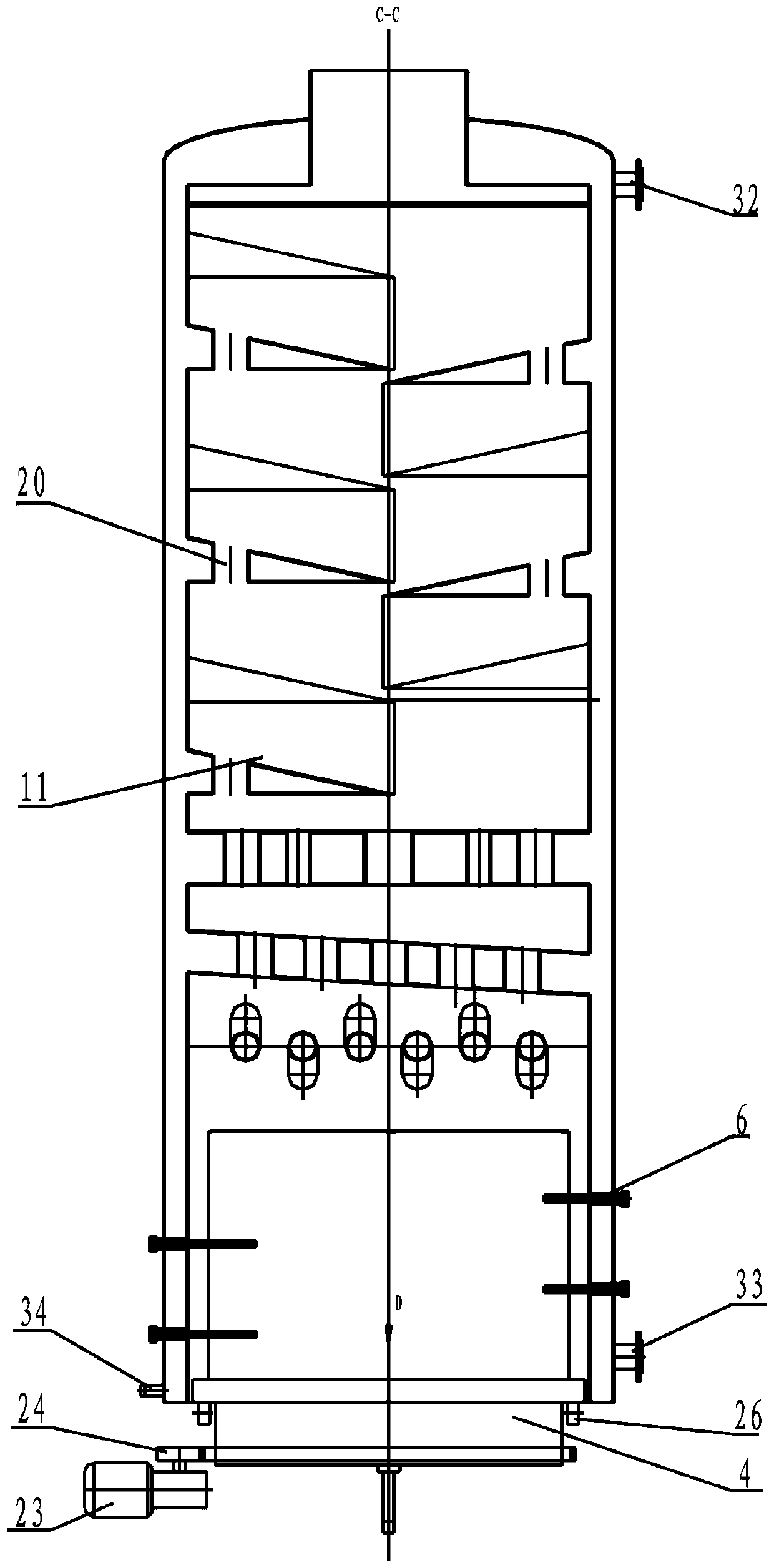

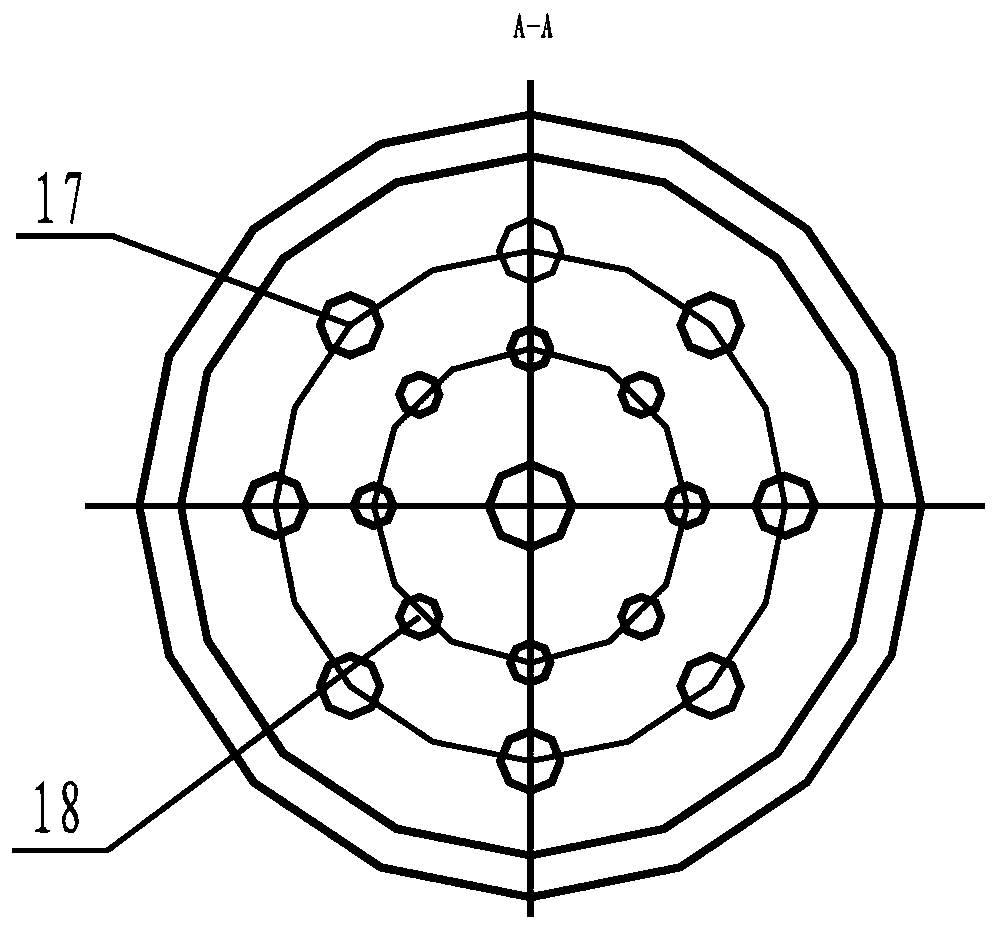

[0045] Such as Figure 1-4 As shown, the embodiment of the present invention discloses a water-cooled rotary grate straw bale burning semi-gasification direct-fired atmospheric hot water boiler, including a straw bale drying chamber 1, a vertical cylindrical boiler shell 2, a boiler inner liner 3, and a water-cooled Rotating grate 4. Among them, the straw bale drying chamber 1 communicates with the bottom of the boiler liner 3; the vertical cylindrical boiler shell 2 is located outside the boiler liner 3, and the interlayer between the two is the boiler water layer; the vertical cylindrical boiler shell 2 has a bottom There are water-cooled rotating grate 4.

[0046] specific,

[0047] The boiler liner 3 includes a main combustion chamber 5 at the bottom. The straw bale drying chamber 1 communicates with the main combustion chamber 5. The side walls of the main combustion chamber 5 are equipped with several bale breaking devices 6 for breaking up straw bales and a The furnace do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com