Straw bale burning direct combustion grain drying hot blast stove

A technology of straw bales and hot blast stoves, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of slow combustion speed, waste of resources, low thermal efficiency, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

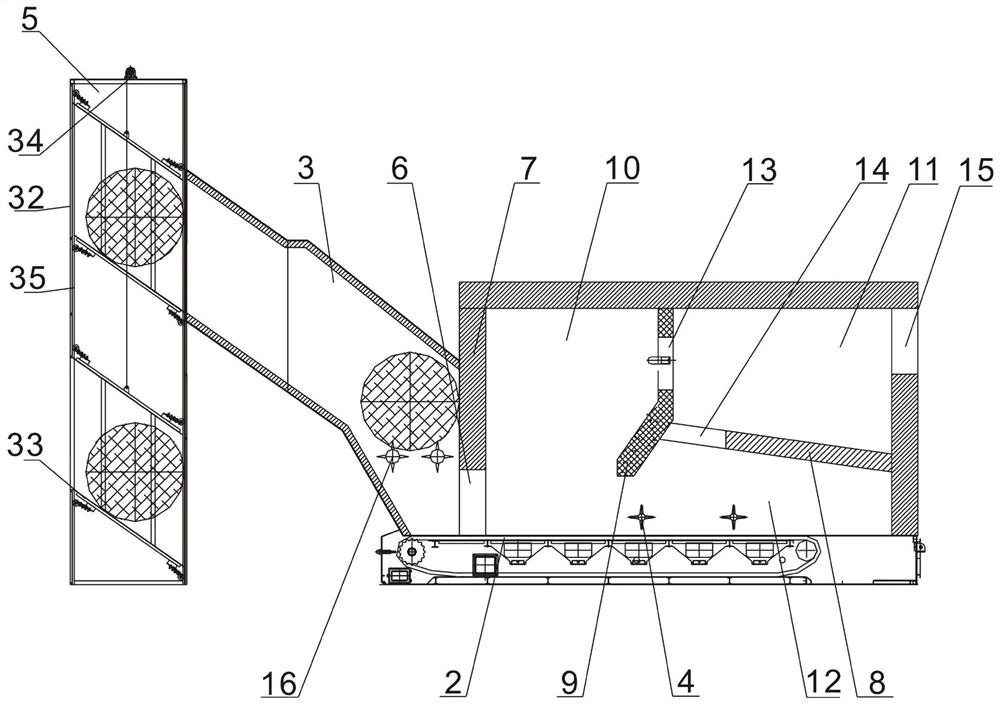

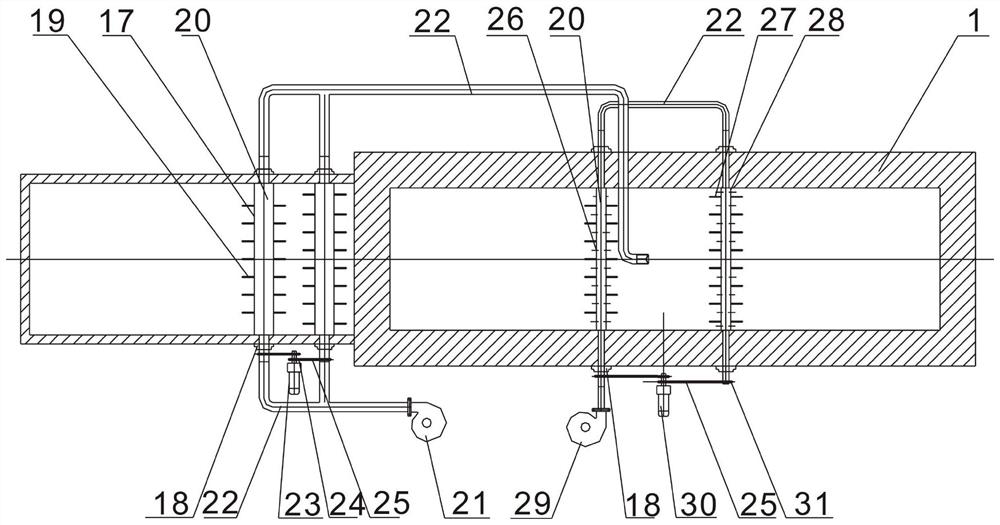

[0046] The following is based on Figure 1-2 A direct-fired grain drying hot air stove for burning straw bundles according to an embodiment of the present invention will be described in detail.

[0047] See attached figure 1 And attached figure 2 , the embodiment of the present invention discloses a direct-fired grain drying hot air stove for straw bundle burning, comprising: a refractory brick hearth 1, a chain grate 2, a straw drying and breaking chamber 3, an air-cooled feeding device 4, and a feeding device 5 ;

[0048] The front wall 7 of the refractory brick furnace 1 is provided with a feed inlet 6, which is used to transport the broken straw into the refractory brick furnace 1 through the chain grate 2, and the rear end of the refractory brick furnace 1 is provided with a rear Arch 8, a partition wall 9 is provided between the front wall 7 and the rear arch 8 of the refractory brick furnace 1, and the partition wall 9, the front wall 7 and the refractory brick furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com