Variable-compression-ratio piston with driving mechanism

A driving mechanism and compression ratio technology, applied in pistons, engine components, machines/engines, etc., can solve the problems of complex structure, low adaptability, poor compactness, etc., and achieve the effects of reliable and accurate work, space saving and vibration reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

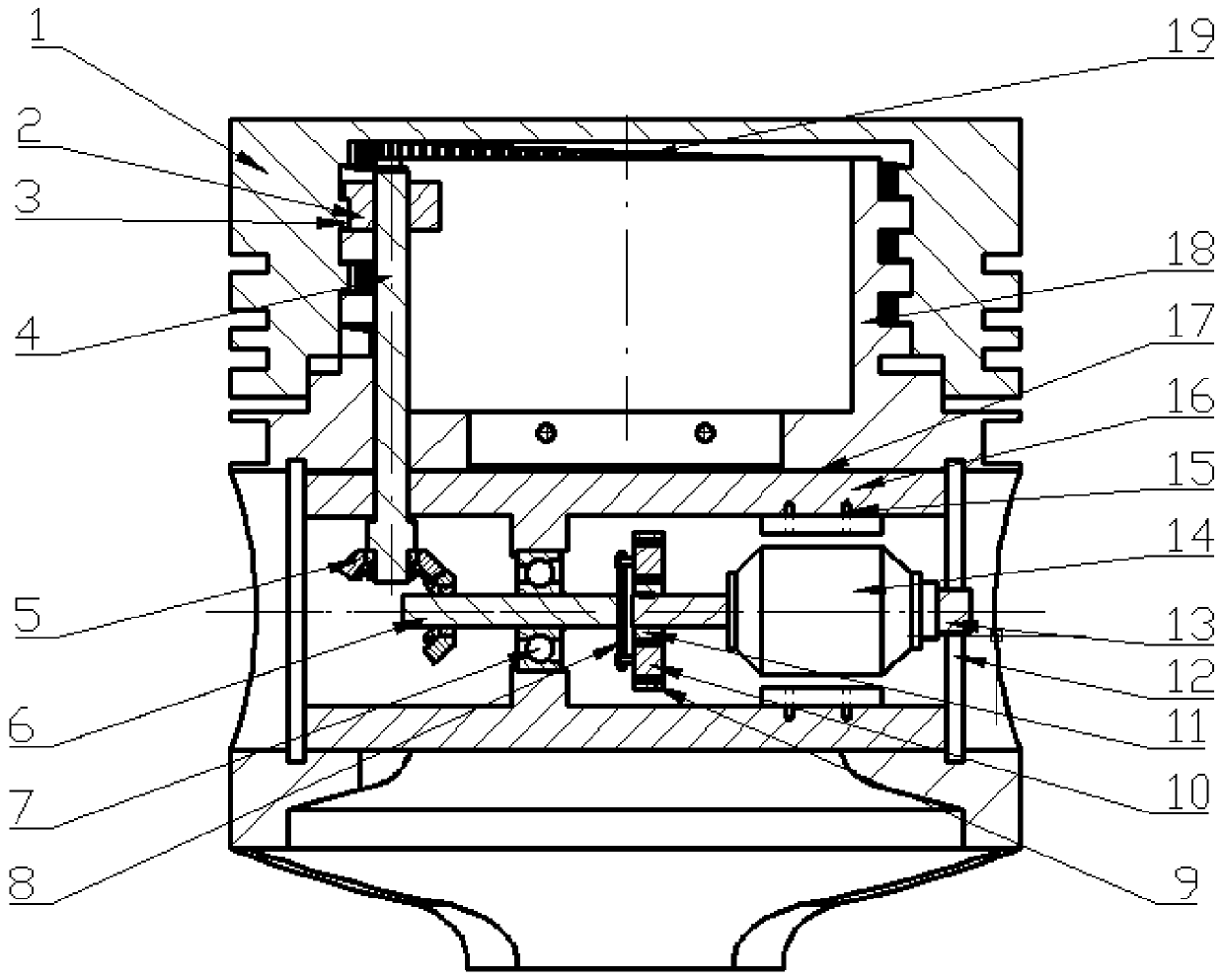

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

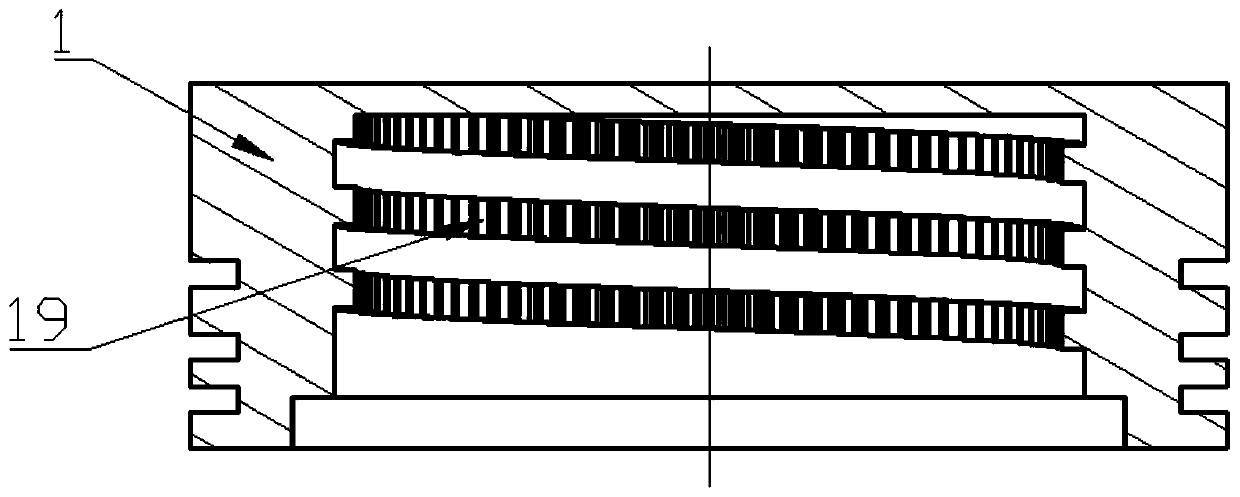

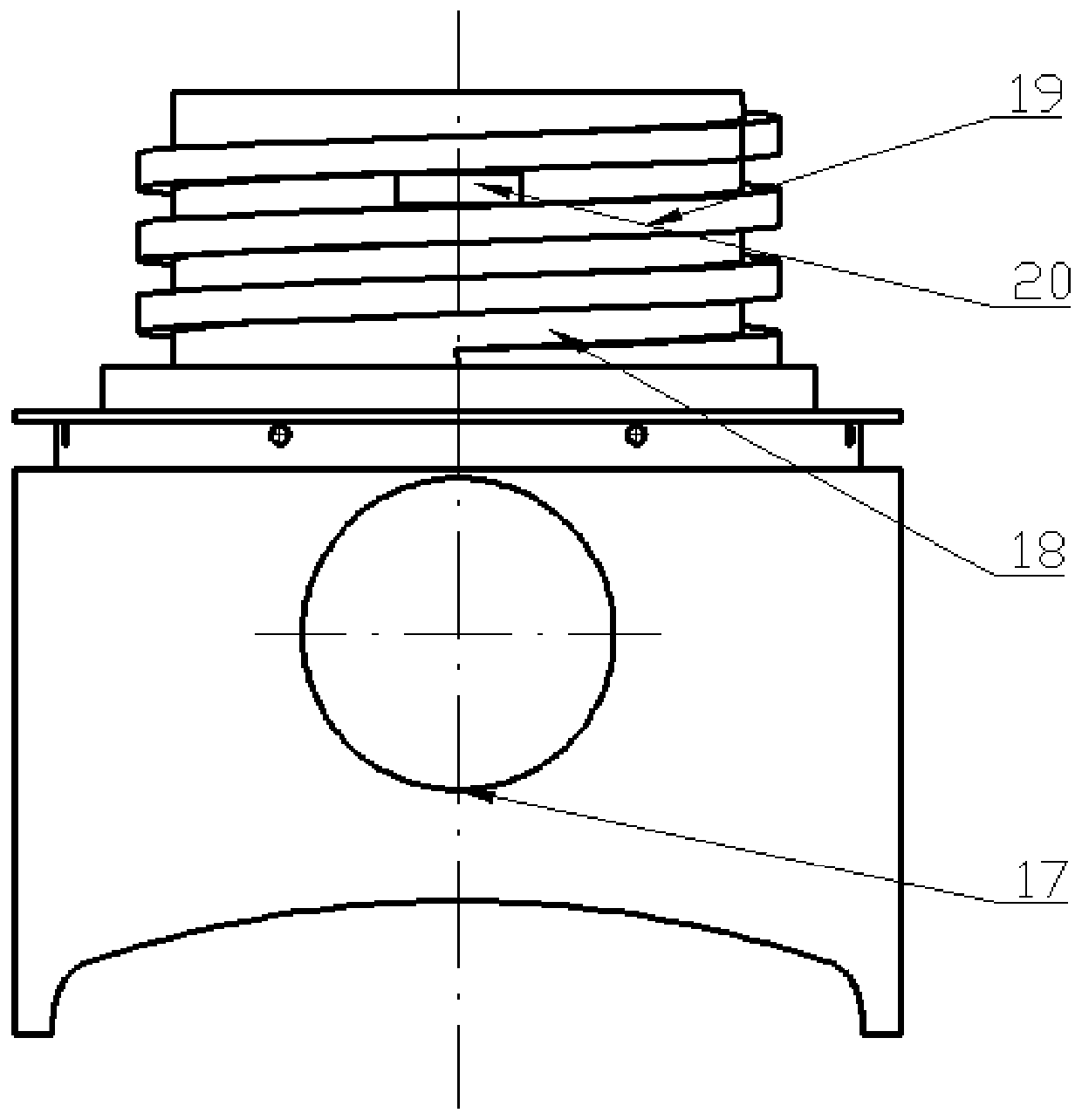

[0031] Such as figure 1 As shown, there is a set of internal teeth 3 meshing with the transmission gear 2 at the trapezoidal thread 19 inside the upper body 1 of the piston head. The trapezoidal thread 19 exists on the inner side of the upper body 1 of the piston head and the outer side of the lower body 18 of the piston head. The two bodies are connected, and the internal teeth 3 are a group of tooth-shaped structures existing at the second thread of the trapezoidal thread 19 on the upper body of the transmission piston head. It is meshed with the transmission gear 2 for transmission. The tooth shape is continuous and vertical to Transmission gear 2 transmits torque to piston head upper body 1; piston head lower body 18 and piston pin 16, piston pin hole 17 are integral parts from top to bottom, and there is an allowable transmission at the second thread of piston head lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com