Cast-in-place concrete separator special for composite light-weight (CL)

A separator and concrete technology, which is applied in the construction, building structure, building material processing and other directions, can solve the problems affecting the apparent state of pouring and building safety, and the pouring of the outer concrete protective layer is not compact, so as to improve the practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

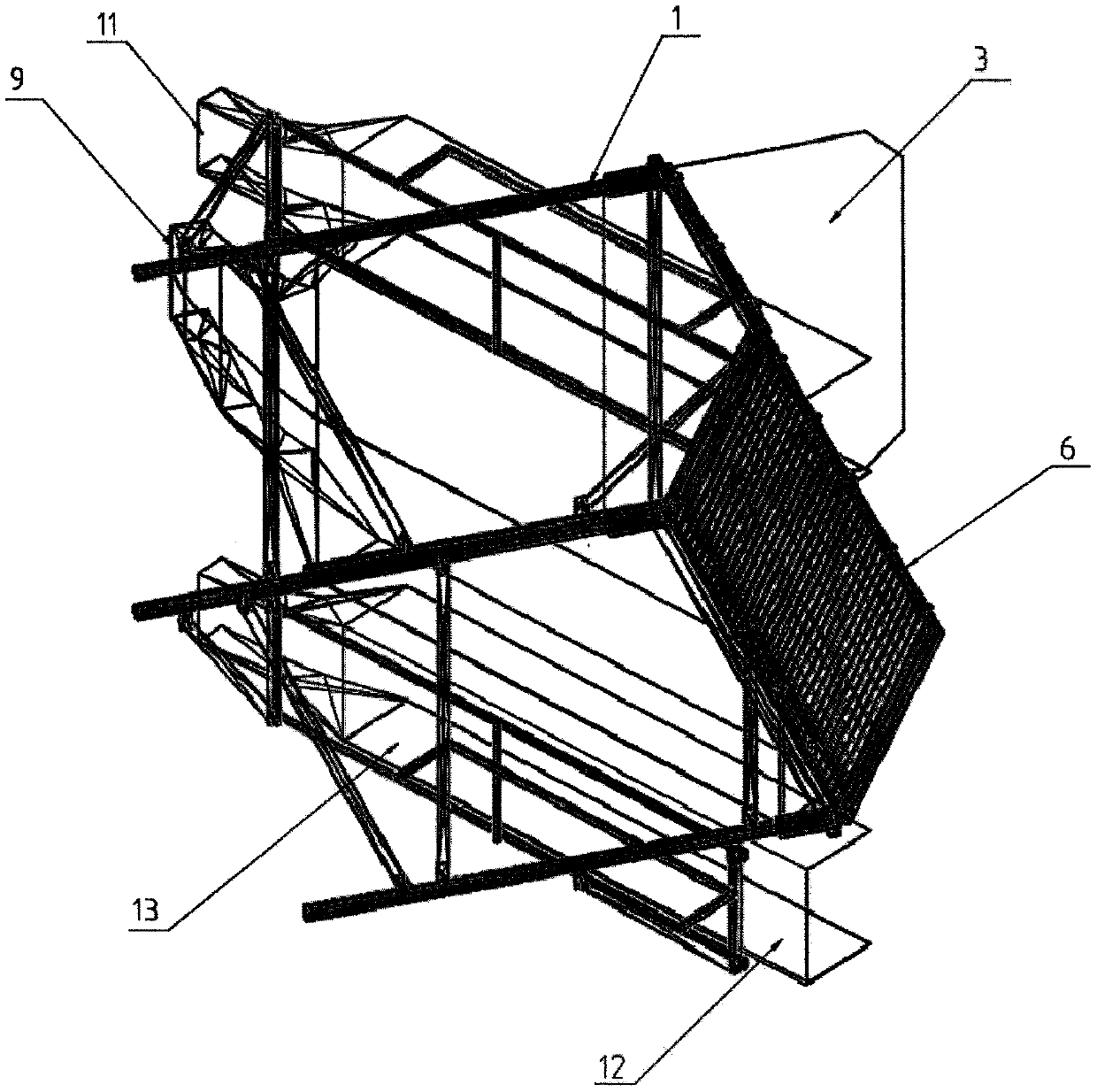

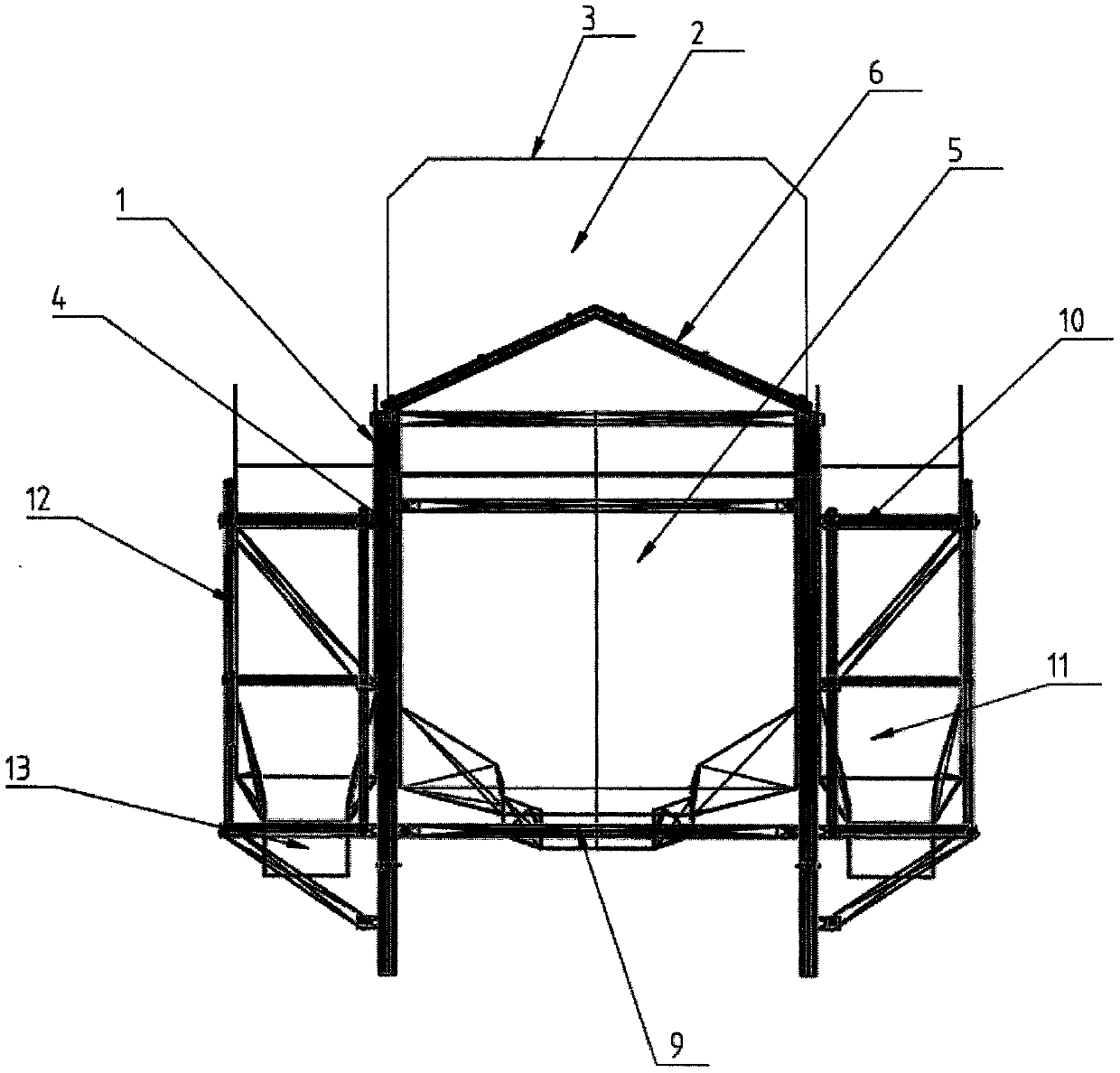

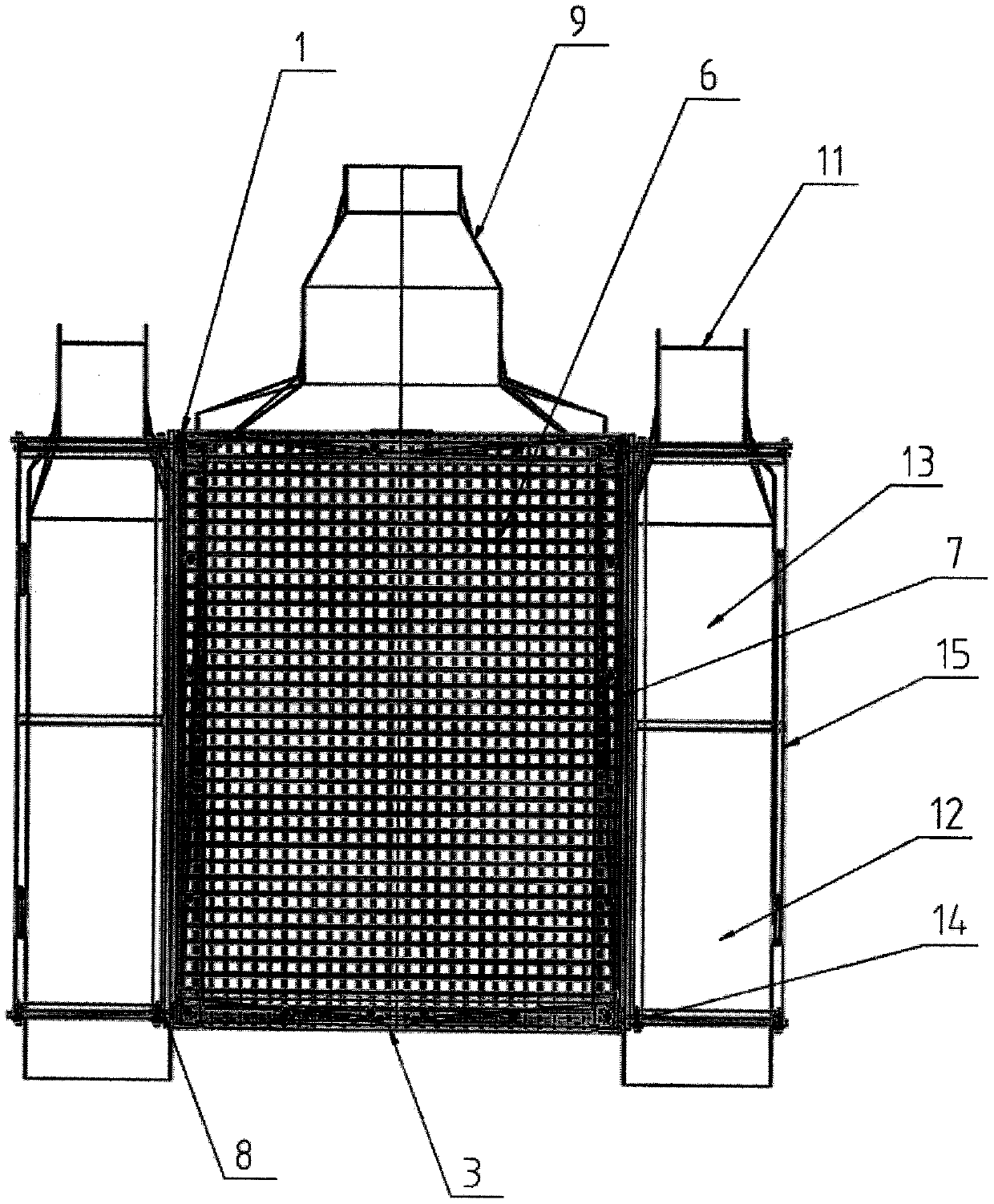

[0026] Such as Figure 1-5 A CL-specific cast-in-place concrete separator shown includes a separator bracket 1, a grouting port 2 is provided on the top of the separator bracket 1, and an overflow prevention baffle 3 is provided on the outside of the grouting port 2. A separation device 4 is provided at the bottom of the grouting port 2;

[0027] Described separation device 4 comprises separation chamber 5, and described separation chamber 5 is provided with separation piece 6, and described separation piece 6 is made of the steel wire mesh sheet of different spacing, and described separation piece 6 is provided with damping pad 7, The shock absorbing pad 7 is provided with a crimping metal buckle 8, and the separating sheet 6 is arranged in the form of a herringbone slope;

[0028] The bottom of the separation chamber 5 is provided with a first slurry outlet 9, and the outer side of the first slurry outlet 9 is provided with a flow diversion groove 10, and the end of the flo...

Embodiment 2

[0036] On the basis of the above embodiments, further, the separator 6 can also be set in the form of an arc surface;

[0037] Including a separator bracket 1, the top of the separator bracket 1 is provided with a grouting port 2, the outside of the grouting port 2 is provided with an anti-overflow baffle 3, and the bottom of the grouting port 2 is provided with a separation device 4;

[0038] Described separation device 4 comprises separation chamber 5, and described separation chamber 5 is provided with separation piece 6, and described separation piece 6 is made of the steel wire mesh sheet of different spacing, and described separation piece 6 is provided with damping pad 7, The shock absorbing pad 7 is provided with a crimping metal buckle 8, and the separating sheet 6 is arranged in the form of a herringbone slope;

[0039] The bottom of the separation chamber 5 is provided with a first slurry outlet 9, and the outer side of the first slurry outlet 9 is provided with a f...

Embodiment 3

[0042] Different from Embodiment 1, the connection form between the separation chamber 5 and the separation sheet 6 can also be connected by a mortise and tenon slot;

[0043] Including a separator bracket 1, the top of the separator bracket 1 is provided with a grouting port 2, the outside of the grouting port 2 is provided with an anti-overflow baffle 3, and the bottom of the grouting port 2 is provided with a separation device 4;

[0044]Described separation device 4 comprises separation chamber 5, and described separation chamber 5 is provided with separation piece 6, and described separation piece 6 is made of the steel wire mesh sheet of different spacing, and described separation piece 6 is provided with damping pad 7, The shock absorbing pad 7 is provided with a crimping metal buckle 8, and the separating sheet 6 is arranged in the form of a herringbone slope;

[0045] The bottom of the separation chamber 5 is provided with a first slurry outlet 9, and the outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com