Alloy material for bearing rolling body and preparation method thereof

A technology of alloy materials and rolling elements, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of radial size, large vibration and noise, and high price, and achieve the effects of improving strength, enhancing hardness, and inhibiting grain growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

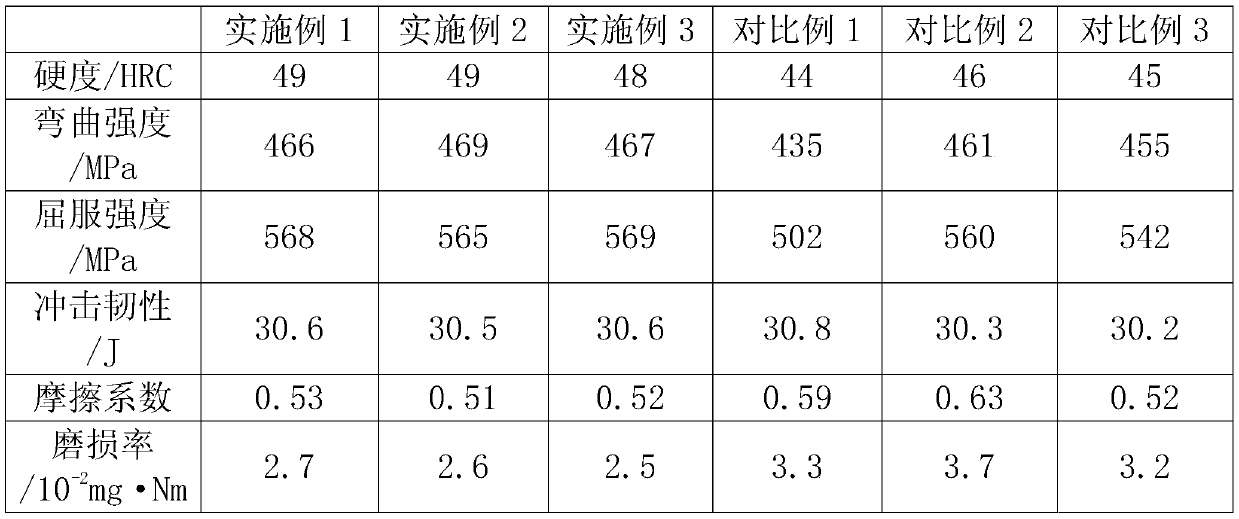

Examples

preparation example Construction

[0039] A method for preparing an alloy material for a bearing rolling body, comprising the following steps:

[0040] Step S1. Mix the metal powders of the base material, add a lubricant, and place them in a cleaned ball mill tank (made of stainless steel). The ball mill tank is evacuated and filled with argon inert gas to prevent the powder from grinding during the ball milling process. Adhesive oxidation, ball milling the mixed powder, ball milling at 250r / min for 2 hours, the ball milling medium is alumina balls, the ball diameters are 10mm, 6mm and 3mm, and the ball-to-material ratio is 10:1;

[0041] Step S2, after the above-mentioned mixed powder is cooled to room temperature, add modified graphene oxide, and continue ball milling at 250r / min for 2h under the protection of argon (divided into two steps of ball milling, which can prevent graphene from being easily wrapped in the composite material) The surface of the metal particles makes it difficult for the metal particl...

Embodiment 1

[0048] An alloy material for a bearing rolling body, made of the following raw materials in parts by weight: 80 parts of base material, 9 parts of lubricant, and 6 parts of modified graphene oxide;

[0049] The alloy material is made by the following steps:

[0050] Step S1. Mix the metal powders of the base material, add lubricant, and place them in a cleaned ball mill tank. The ball mill tank is evacuated and filled with argon inert gas to prevent the powder from bonding and oxidation during the ball milling process. The mixed powder is ball milled for 2 hours at 250r / min, the ball milling medium is alumina balls, the ball diameters are 10mm, 6mm and 3mm, and the ball-to-material ratio is 10:1;

[0051] Step S2, after the above-mentioned mixed powder is cooled to room temperature, then add modified graphene oxide, and continue ball milling at 250r / min for 2h under the protection of argon;

[0052] Step S3, the mixed powder after ball milling is sintered under the sintering ...

Embodiment 2

[0055] An alloy material for a bearing rolling body, made of the following raw materials in parts by weight: 90 parts of a base material, 10 parts of a lubricant, and 6.5 parts of modified graphene oxide;

[0056] The alloy material is made by the following steps:

[0057] Step S1. Mix the metal powders of the base material, add lubricant, and place them in a cleaned ball mill tank. The ball mill tank is evacuated and filled with argon inert gas to prevent the powder from bonding and oxidation during the ball milling process. The mixed powder is ball milled for 2 hours at 250r / min, the ball milling medium is alumina balls, the ball diameters are 10mm, 6mm and 3mm, and the ball-to-material ratio is 10:1;

[0058] Step S2, after the above-mentioned mixed powder is cooled to room temperature, then add modified graphene oxide, and continue ball milling at 250r / min for 2h under the protection of argon;

[0059] Step S3, the mixed powder after ball milling is sintered under the sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com