A double-doped calcium aluminate type near-infrared reflective pigment and its preparation method

A reflective pigment, near-infrared technology, used in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides double-doped CaAl described in the above technical scheme 2 o 4 The preparation method of type near-infrared reflective pigment comprises the following steps:

[0029] (1) Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , Fe(NO 3 ) 3 Mix with water, citric acid, and ethylene glycol to obtain a mixed solution;

[0030] (2) heating the mixed solution to obtain a sol;

[0031] (3) The sol is dried and calcined in sequence to obtain the double-doped CaAl 2 o 4 type near-infrared reflective pigments.

[0032] The present invention will Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , Fe(NO 3 ) 3 Mix with water, citric acid, and ethylene glycol to obtain a mixed solution. In the present invention, the Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 and Fe(NO 3 ) 3 The molar ratio is preferably 28.3:5.0:(55.0-61.7):(5.0-11.7), more preferably 28.3:5.0:(58.0-60.0):(8.0-10.0). In the present invention, the Ca(NO 3 ) 2 Preferably Ca(NO 3 )...

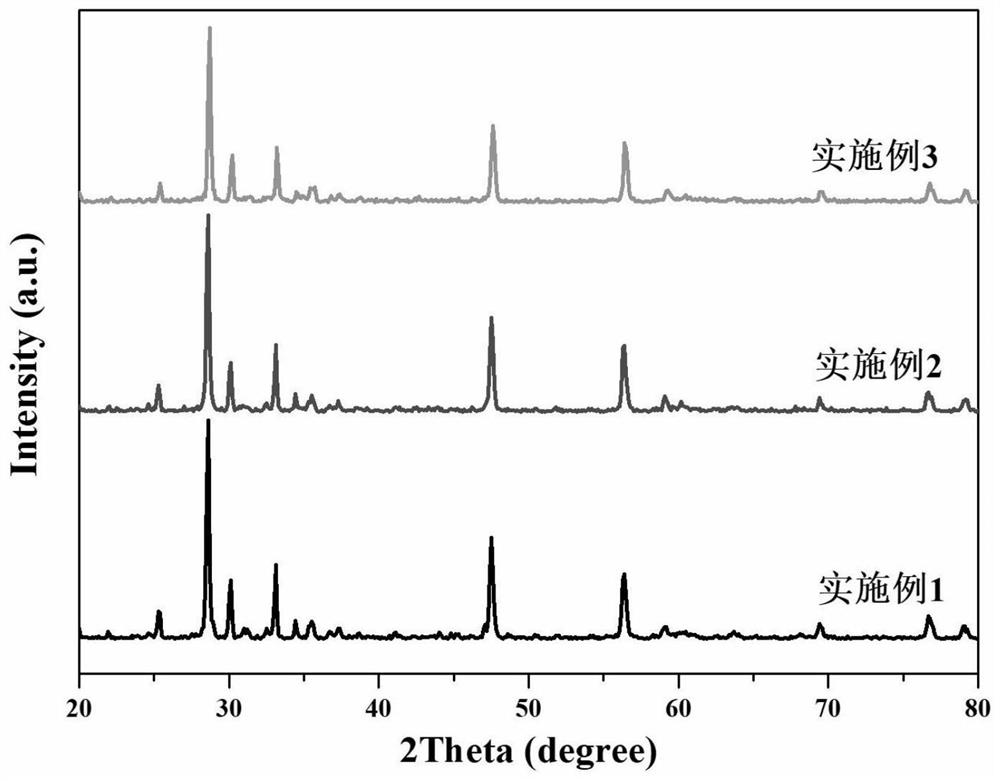

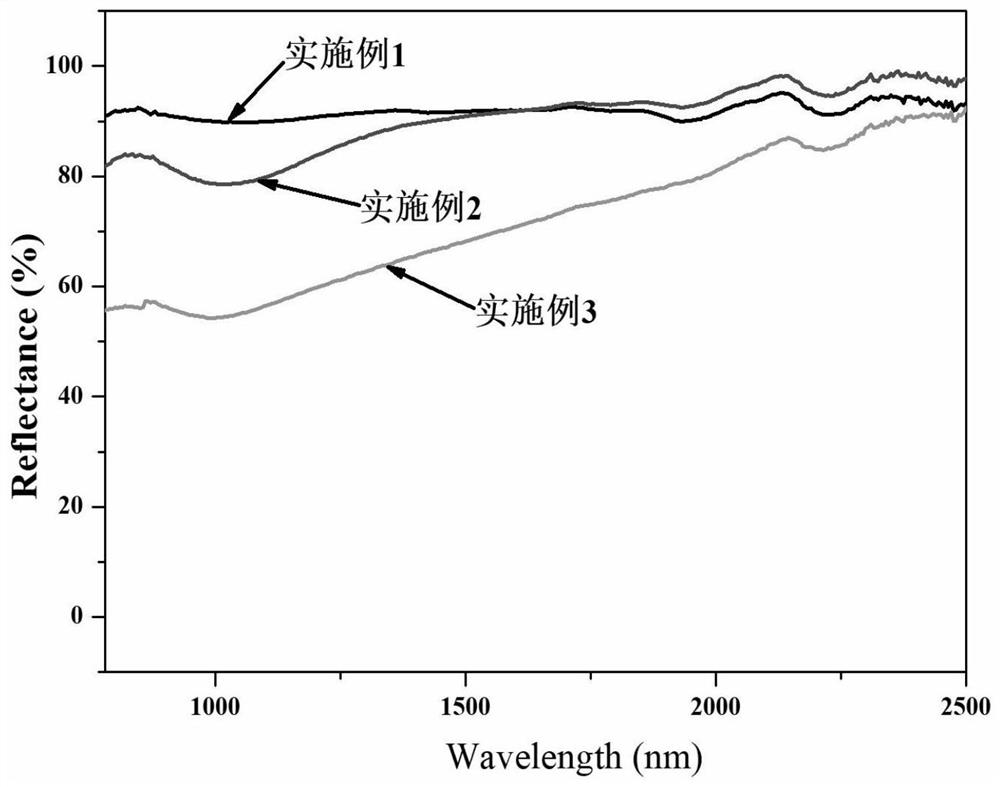

Embodiment 1

[0040] Prepare according to the mole percentage of metal elements: Ca(NO 3 ) 2 4H 2 O is 28.3%, Ce(NO 3 ) 3 ·6H 2 O is 5%, Al(NO 3 ) 3 9H 2 O is 61.7%, Fe(NO 3 ) 3 9H 2 O is 5% mixed with water, the mass ratio of water and metal nitrate is 5:1, stirred until completely dissolved to obtain a mixed solution; then citric acid and ethylene glycol are added to the mixed solution, citric acid and the above metal The molar ratio of ions is 3:1, the molar ratio of ethylene glycol and citric acid is 2:3, stir until completely dissolved; then put the mixed solution into a water bath for water bath heating, the heating temperature is 60°C, and the heating time is 4h , to obtain a sol; then put the sol into an oven for drying at a drying temperature of 120° C. and a drying time of 12 hours to obtain a xerogel. Then grind the obtained xerogel and put it into a muffle furnace for calcination. Under the atmosphere of air, start to heat up from room temperature at a rate of 5°C / min...

Embodiment 2

[0042] Prepare according to the mole percentage of metal elements: Ca(NO 3 ) 2 4H 2 O is 28.3%, Ce(NO 3 ) 3 ·6H 2 O is 5%, Al(NO 3 ) 3 9H 2 O is 58.4%, Fe(NO 3 ) 3 9H 2O is 8.3% mixed with water, the mass ratio of water to metal nitrate is 6:1, stirred until completely dissolved to obtain a mixed solution; then citric acid and ethylene glycol are added to the mixed solution, citric acid and the above metal The molar ratio of ions is 3:1, the molar ratio of ethylene glycol and citric acid is 2:3, stir until completely dissolved; then put the mixed solution into a water bath for water bath heating, the heating temperature is 80°C, and the heating time is 2h , to obtain a sol; then put the sol into an oven for drying at a drying temperature of 110° C. and a drying time of 14 hours to obtain a xerogel. Then grind the obtained xerogel and put it into a muffle furnace for calcination. Under the atmosphere of air, start to heat up from room temperature at a rate of 5°C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com