Phase change heat buffer type shipboard flame baffle

A flame baffle and phase change heat technology, applied in the field of flame baffles, can solve the problems of limited application, inability to store and release heat by a phase change energy storage device, low thermal conductivity, etc., and achieve improved safety and efficient heat absorption. Excellent effect on heat dissipation and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail:

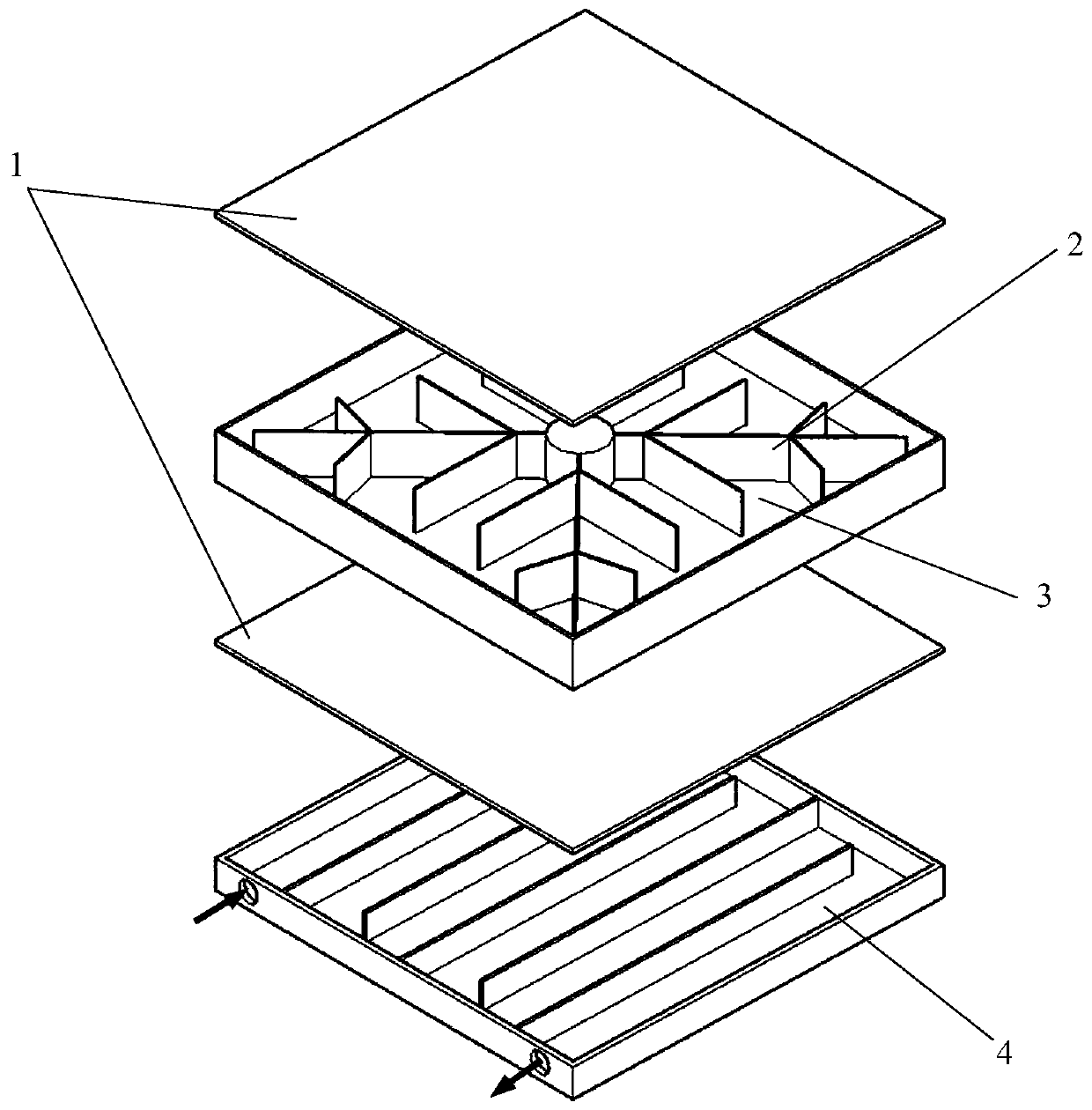

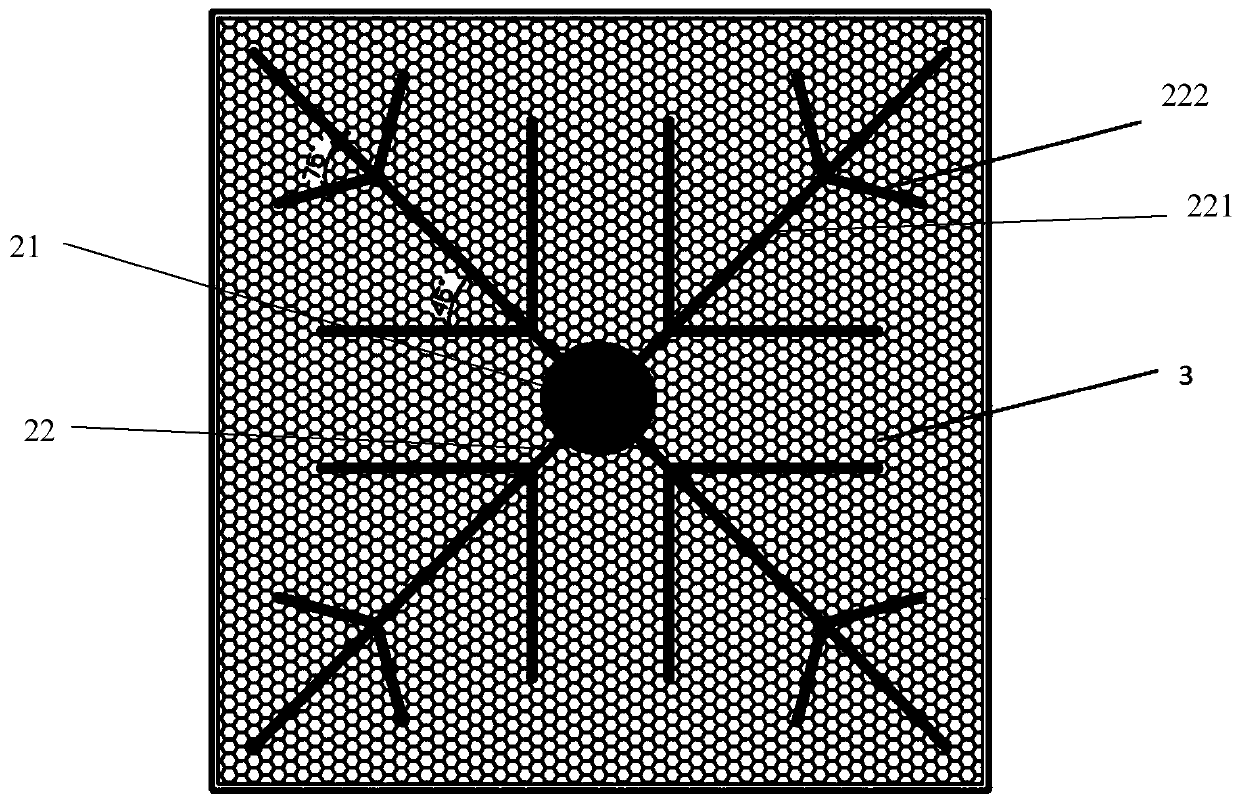

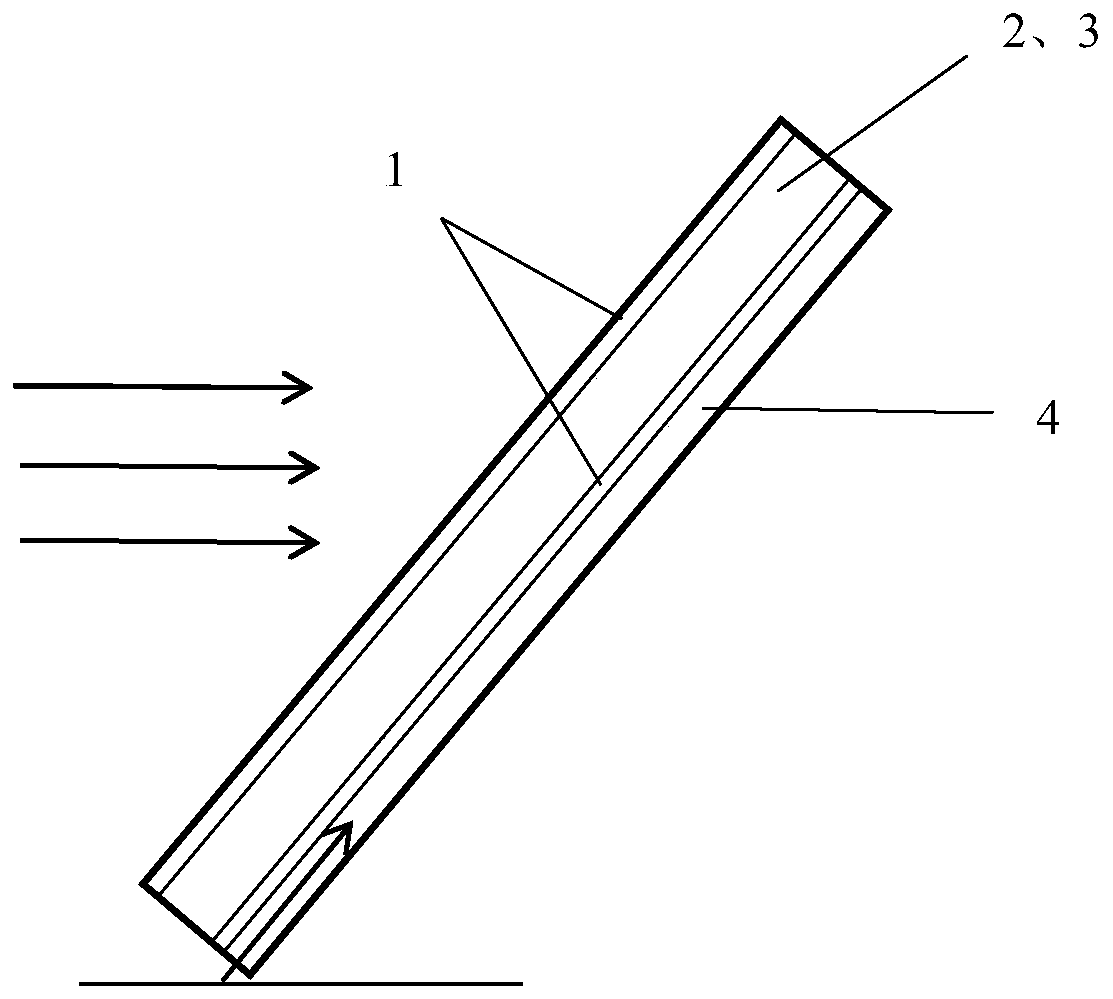

[0025] figure 1 Shown is a schematic diagram of the three-dimensional structure of the shipboard flame shield, which is composed of a heat conducting plate 1 , a heat spreading fin 2 , a phase change material 3 and a heat exchange layer 4 . The heat conduction plate 1 is located on the upper and lower surfaces of the heat dissipation structure layer, and is connected by the heat spreading fins 2 , and the phase change material 3 fills the gap between the heat spreading fins 2 and the heat conduction plate 1 . The heat exchange layer 4 is attached to the lower surface of the heat conduction plate 1, and is used to absorb the heat of the heat dissipation structural layer. The cooling water circulation channel in the heat exchange layer 4 is a grid-like serpentine channel, and the water flow direction is shown by the arrow. The cooling water enters and exits on the same side t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com