Concrete product capable of being solidified at room temperature and preparation method and application therof

A concrete product, curing technology at room temperature, applied in the direction of chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve the problems of efflorescence, capillary pollutants, etc., to improve the binding force and Effects of compactness, improved adhesion, and enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

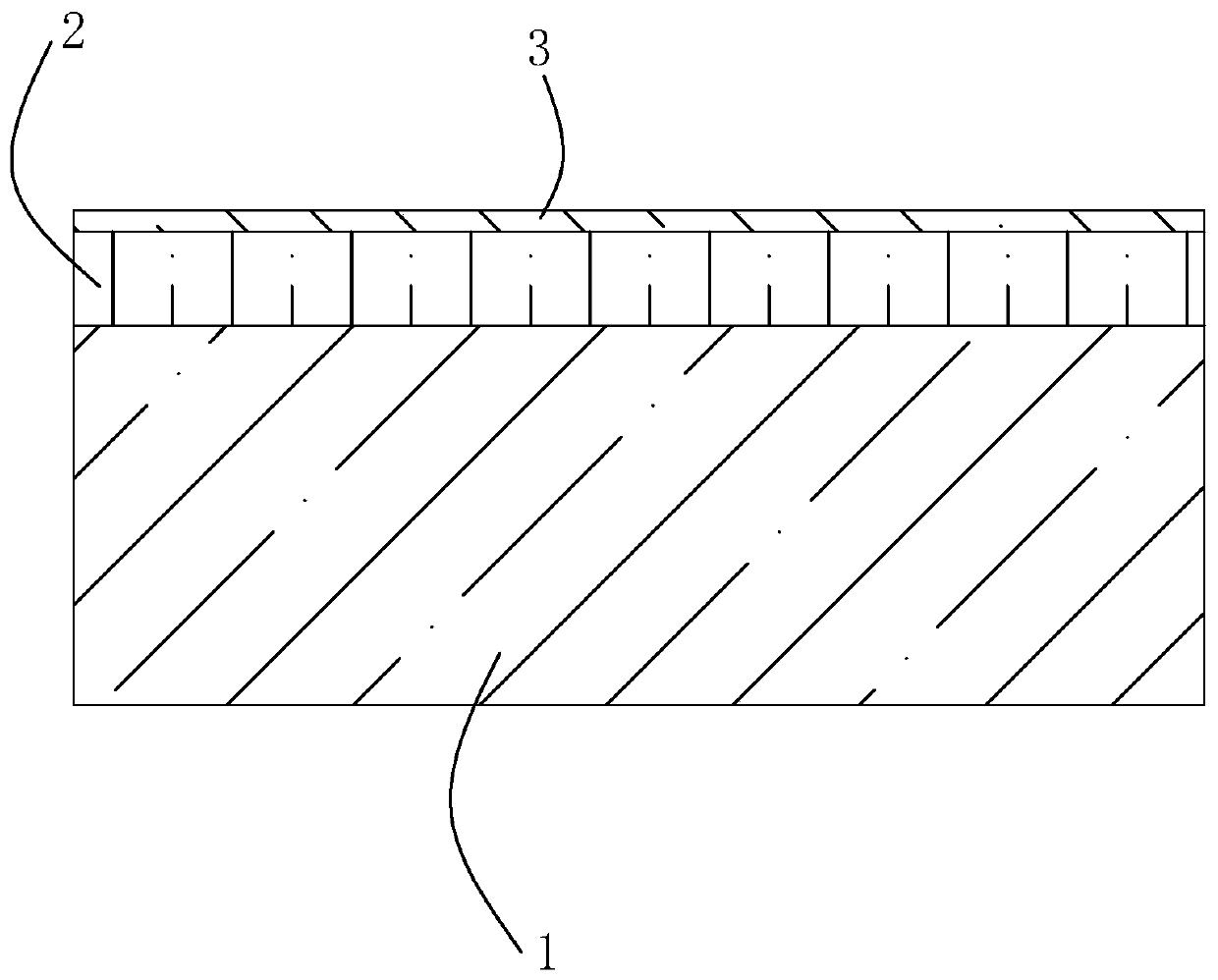

Image

Examples

preparation example 1

[0041] Mix and stir 3kg of fluorocarbon resin, 0.02kg of wetting and dispersing agent, and 1kg of solvent evenly, then add 3.6kg of pigment, disperse and stir evenly, and grind until the fineness is less than 25 microns to obtain pigment slurry. Mix and stir the pigment slurry with 10kg of fluorocarbon resin, add 0.02kg of defoamer and 0.02kg of leveling agent during the stirring process, add 1kg of solvent after stirring evenly, and set aside the mixed material after stirring; weigh 1kg of curing agent is added to the above-mentioned uniformly stirred mixture before use, and it can be stirred evenly. The fluorocarbon resin used in this preparation example is LF-200, the wetting and dispersing agent is BYK-163, the solvent is dimethyl carbonate, the pigment is carbon black, the defoamer is BYK-065, and the leveling agent is BYK-330. The curing agent adopts TKA-75.

preparation example 2

[0043] Mix and stir 2kg of fluorocarbon resin, 0.1kg of wetting and dispersing agent, and 1kg of solvent evenly, then add 2.7kg of pigment, disperse and stir evenly, and grind to a fineness of less than 25 microns to obtain a pigment slurry. Mix and stir the pigment slurry with 6kg of fluorocarbon resin, add 0.05kg of defoamer and 0.15kg of leveling agent during the stirring process, add 1.5kg of solvent after stirring evenly, and set aside after stirring; Take 0.8kg of curing agent, add it to the above-mentioned uniformly stirred mixture before use, and stir evenly. The fluorocarbon resin used in this preparation example is GK-570, the wetting and dispersing agent is BYK-2001, the solvent is ethyl acetate, the pigment is carbon black, the defoamer is BYK-066N, and the leveling agent is BYK-358. The agent uses N3300.

preparation example 3

[0045] Mix and stir 4kg of fluorocarbon resin, 0.06kg of wetting and dispersing agent, and 1.6kg of solvent evenly, then add 4.6kg of pigment, disperse and stir evenly, and grind to a fineness of less than 25 microns to obtain a pigment slurry. Mix and stir the prepared pigment slurry with 11kg of fluorocarbon resin, add 0.04kg of defoamer and 0.16kg of leveling agent during the stirring process, and then add 2kg of solvent after stirring evenly, and the mixed material after stirring is set aside ; Weigh 1.2kg of curing agent, add it to the above-mentioned uniformly stirred mixture before use, and stir evenly. The fluorocarbon resin used in this preparation example is CC-03, the wetting and dispersing agent is BYK-2050, the solvent is ethyl acetate, the pigment is carbon black, the defoamer is BYK-065, and the leveling agent is BYK-358. The agent adopts TSE-100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com