A kind of composite photocatalytic material and preparation method of tin nanoparticle-modified tritin tetraoxide nanosheets with oxygen vacancies

A technology of tritin tetroxide and composite photocatalysis, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to improve the utilization rate of light energy, promote separation, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ① weighed 5mM stannous chloride dihydrate (SnCl 2 · 2h 2 O, 1.128g), 12.5mM sodium citrate dihydrate (Na 3 C 6 Hide 5 O 7 · 2h 2 O, 3.6367g) was dissolved in 12.5ml of deionized water, stirred for 10min, ultrasonic 10min, an aqueous solution containing 12.5ml 0.2M sodium hydroxide was then added to adjust the PH to 5.5. Then ultrasonic 30min, stirred for 1h, dispersed and dissolved completely;

[0027] ② The above solution was transferred to a 50ml autoclave, for 12h at 180 [deg.] C;

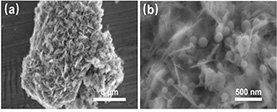

[0028] ③ After completion of the reaction the reaction vessel was cooled to room temperature naturally, and washed 3-5 times with deionized water and the resulting product is ethanol, respectively, and then placed in a thermostatic blast oven kept 10h at 80 ℃, obtained as a pale yellow powder oxide tin sheet;

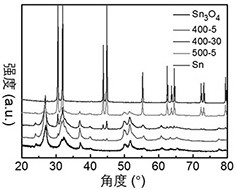

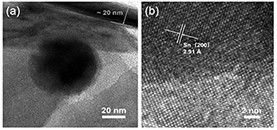

[0029] ④ tetroxide made taking the above steps three pieces tin powder in a quartz boat which was then placed in a tube furnace, in a mixed atmosphere of hydrogen and argon, and heated...

Embodiment 2

[0031] ① weighed 5mM stannous chloride dihydrate (SnCl 2 · 2h 2 O, 1.128g), 12.5mM sodium citrate dihydrate (Na 3 C 6 Hide 5 O 7 · 2h 2 O, 3.6367g) was dissolved in 12.5ml of deionized water, stirred for 10min, ultrasonic 10min, an aqueous solution containing 12.5ml 0.2M sodium hydroxide was then added to adjust the PH to 5.5. Then ultrasonic 30min, stirred for 1h, dispersed and dissolved completely;

[0032] ② The above solution was transferred to a 50ml autoclave, for 12h at 180 [deg.] C;

[0033] ③ After completion of the reaction the reaction vessel was cooled to room temperature naturally, and washed 3-5 times with deionized water and the resulting product is ethanol, respectively, and then placed in a thermostatic blast oven kept 10h at 80 ℃, obtained as a pale yellow powder oxide tin sheet;

[0034] ④ tetroxide made taking the above steps three pieces tin powder in a quartz boat which was then placed in a tube furnace, in a mixed atmosphere of hydrogen and argon, and heated...

Embodiment 3

[0036] ① weighed 5mM stannous chloride dihydrate (SnCl 2 · 2h 2 O, 1.128g), 12.5mM sodium citrate dihydrate (Na 3 C 6 Hide 5 O 7 · 2h 2O, 3.6367 g) was dissolved in 12.5 ml of deionized water, stirred for 10 min, ultrasonic 10min, then adding 12.5 ml of aqueous solution containing 0.2 M sodium hydroxide, and adjusted pH of 5.5. Then ultrason for 30 min, stirred for 1 h, which is completely dispersed;

[0037] 2 Transfer the above solution to 50 ml of the reaction kettle, reacted at 180 ° C for 12 h;

[0038] 3 After the reaction, the reaction kettle was naturally cooled to room temperature, and the resulting product was washed 3 to 5 times with deionized water and anhydrous ethanol, and then placed at a constant temperature blast drying tank at 80 ° C for 10 h, resulting in a pale yellow powder Tetoxide nanotinium;

[0039] 4 Take the above steps to the end of the quartzcea, then placed in the tube furnace, heated to 500 ° C in a mixed atmosphere of hydrogen and argon, heat insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com